A semiconductor structure with low internal loss, low resistance and high efficiency and its preparation method

A semiconductor and low-resistance technology, applied in the field of low-internal loss, low-resistance, high-efficiency semiconductor structure and its preparation, can solve the problems that the luminous efficiency of light-emitting semiconductor devices needs to be improved, so as to optimize series resistance and internal loss, reduce internal loss, and improve The effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

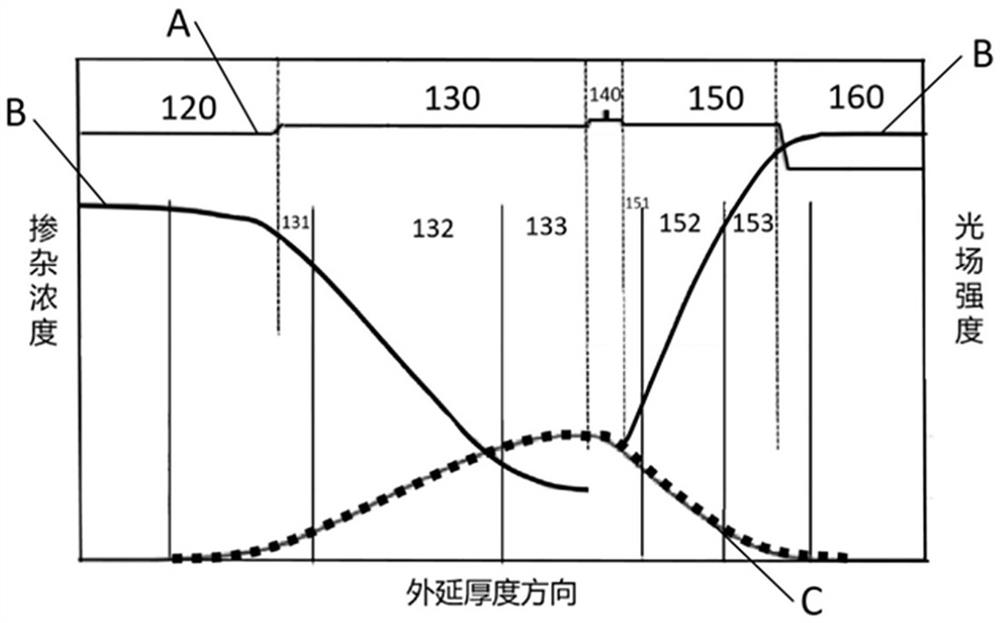

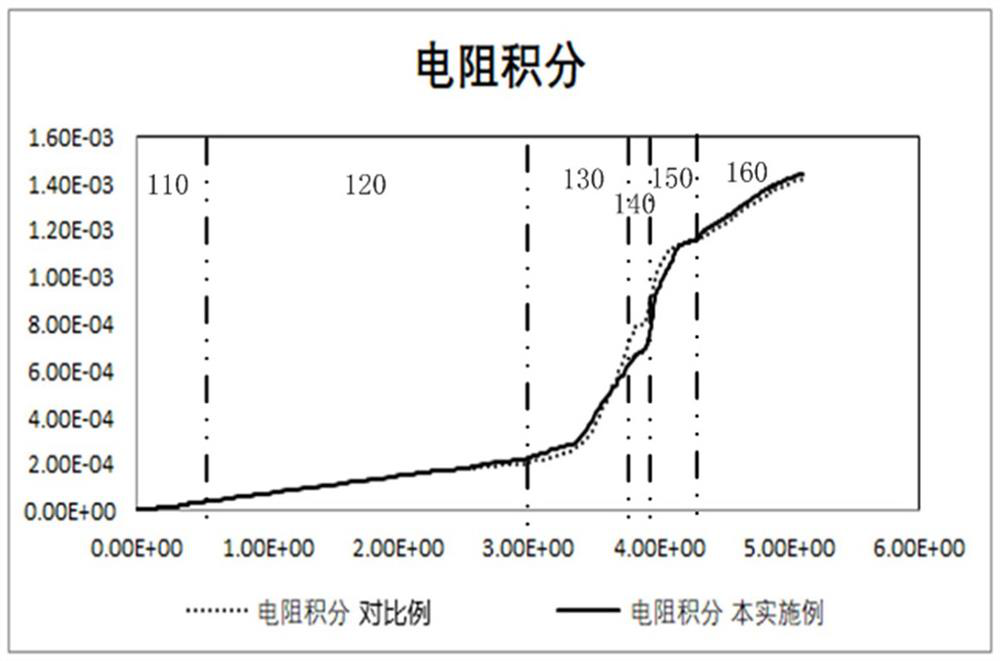

[0027] In addition to power and wavelength, the electro-optical conversion efficiency is the most important indicator of light-emitting semiconductor structures, which directly affects the power consumption and reliability of light-emitting semiconductor structures. The light-emitting semiconductor structure with high electro-optical efficiency not only has less waste heat and high reliability, but also can simplify the thermal management system of the whole system, greatly improving the application level of the light-emitting semiconductor structure. The following is the electrical-to-optical conversion efficiency formula of a light-emitting semiconductor structure:

[0028]

[0029] The electro-optical conversion efficiency that determines the light-emitting semiconductor structure is mainly divided into four items, the first item is the internal quantum efficiency ; The second term is the loss of the resonant cavity of the light-emitting semiconductor structure ; The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com