Purification method suitable for large-scale plasmid DNA production

A purification method and plasmid technology, applied in biochemical equipment and methods, DNA preparation, chemical instruments and methods, etc., can solve the problems of high cost, easy collapse, and large diameter of chromatographic columns, and achieve low cost, small diameter, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Bacteria solution lysing

[0043] After high-density fermentation of engineering bacteria, the bacteria are collected by high-speed centrifugation and resuspended in the resuspension buffer; or the concentrated bacterial solution is collected through a hollow fiber column and replaced with a resuspension buffer; the lysate is added to the bacterial suspension and mixed gently After the lysis is completed, add the neutralizing solution and mix evenly to stop the reaction.

Embodiment 2

[0044] Embodiment 2 bacterial liquid lysates concentrate

[0045] After clarifying the lysate obtained in Example 1 with a depth filter or a hollow fiber column, use a tangential flow ultrafiltration system to concentrate through a mold bag or a hollow fiber column with a pore size of 100-500kD, and then use a pH value of 6.5-7.5 The ion-exchange equilibrium buffer is changed, and the change ratio is 3-5 times the volume of the concentrated feed solution.

Embodiment 3

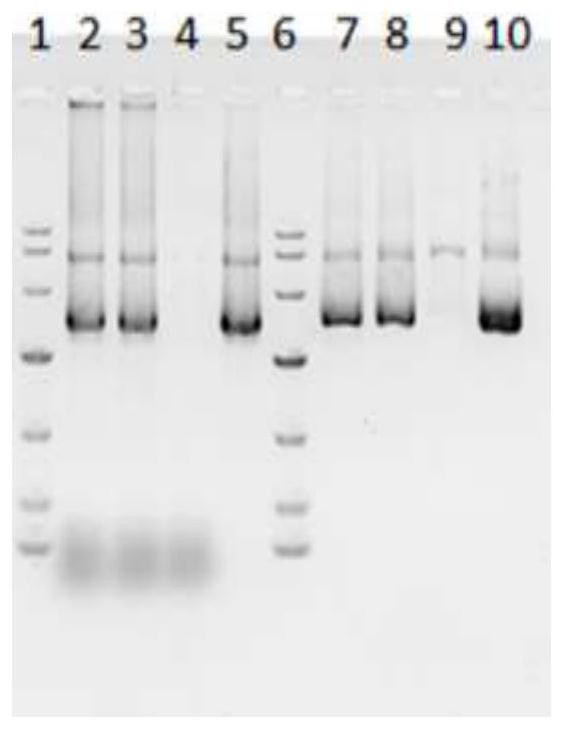

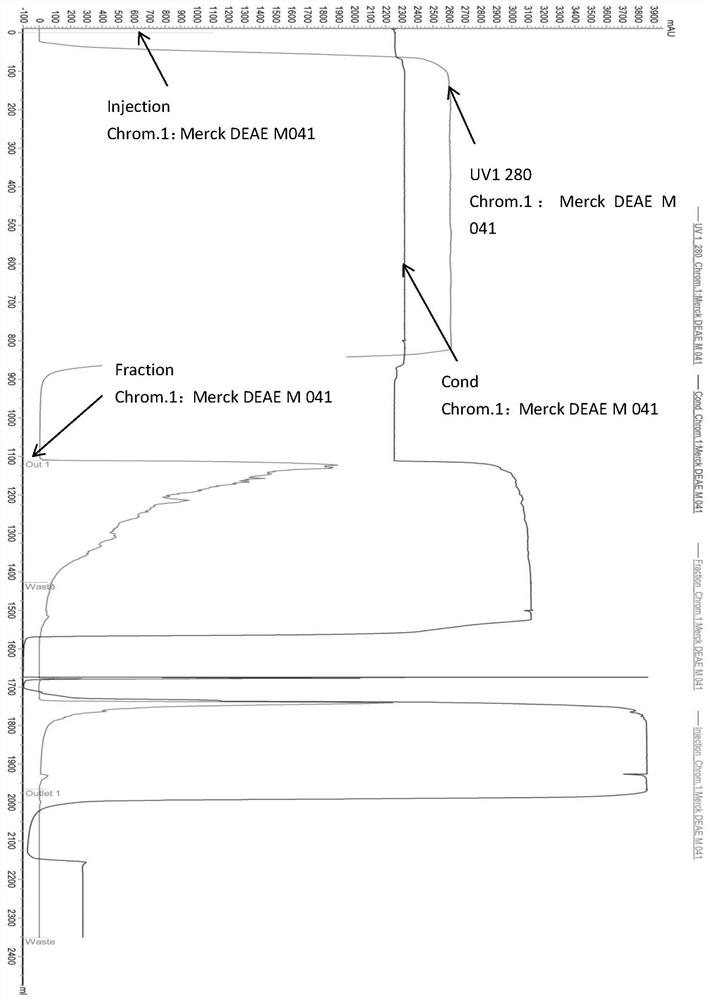

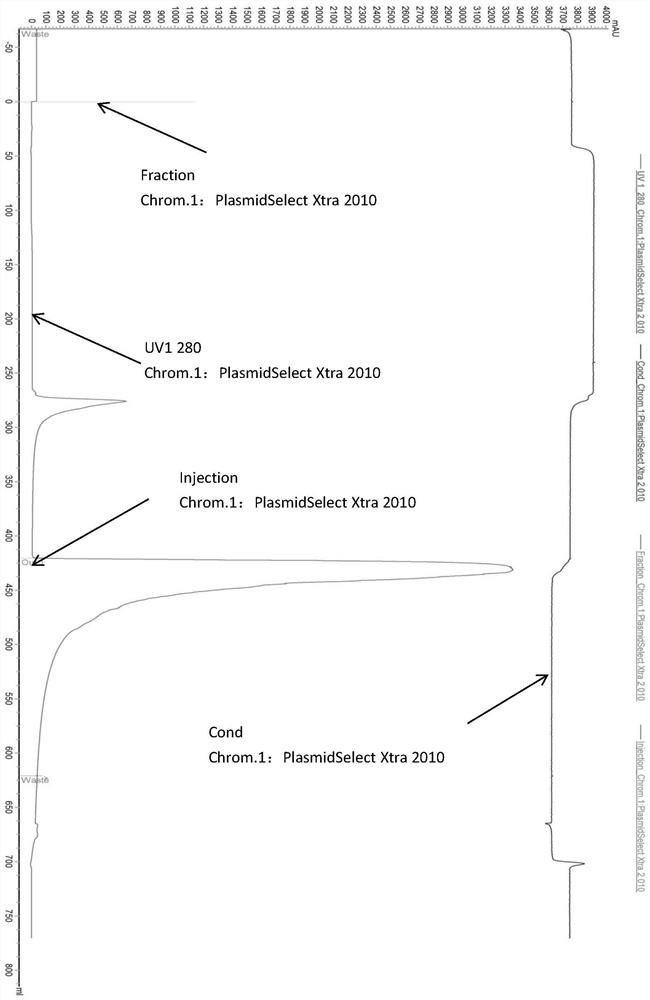

[0046] Embodiment 3 ion exchange chromatography

[0047] In the AKTA chromatographic system of GE Company, the ion-exchange chromatography column is balanced with ion-exchange equilibration buffer, and 3-5 column volumes are balanced; the concentrated solution after clarification in Example 2 is loaded to the ion-exchange chromatography column; After the end, rinse the chromatography column with equilibration buffer for 3-5 column volumes until the absorbance at 280nm drops to near the baseline level, and do not collect the peaks during loading and column washing;

[0048]Elute with elution buffer, wash 3-5 column volumes, collect the peak, stop collecting when the absorbance at 280nm drops to near baseline level; wash the chromatography column with 0.5M NaOH, wash 3-5 columns Volume, until the absorbance at 280nm drops to near the baseline level, do not collect the flushing solution. There are 3 main peaks in the chromatogram, wherein the main component of the first peak is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com