Durable super-hydrophobic candle ash coating and preparation method thereof

A super-hydrophobic and durable technology, applied in coatings, metal material coating processes, devices for coating liquids on surfaces, etc., can solve problems such as coating damage, surface roughness difficult to control, and low life, and achieve improved The effect of corrosion resistance, good mechanical stability, and superior self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

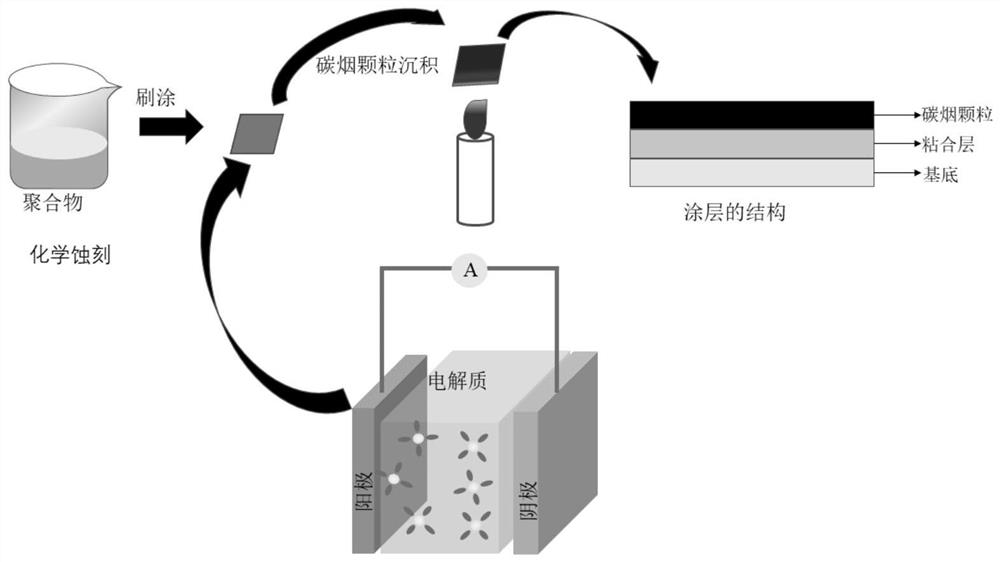

[0029] Such as figure 1 As shown in the preparation of durable superhydrophobic candle soot coating, the specific steps are as follows:

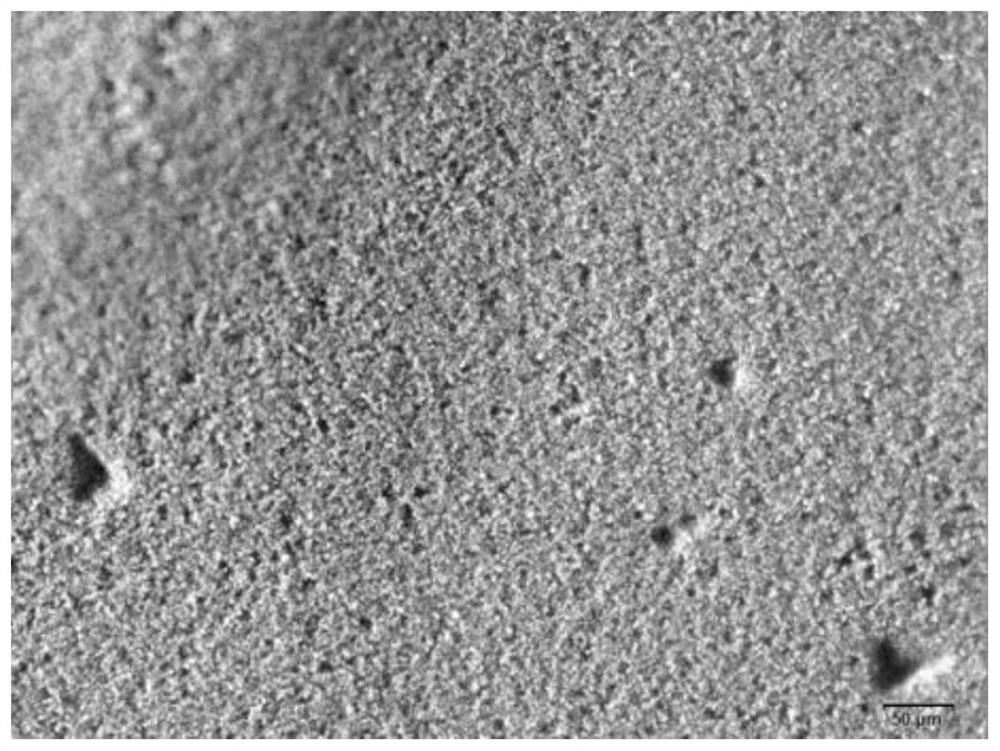

[0030] Step 1): Immerse a 2cm×2cm×0.25cm copper sheet and a stainless steel sheet with a purity of 99.99% in a 95% ethanol solution, and clean it with an ultrasonic cleaner (set at 25°C) for 10 minutes to remove impurities on the surface of the substrate and grease. The copper piece is connected to the anode of the power supply, the stainless steel piece is connected to the cathode of the power supply, and the copper piece and the stainless steel piece are immersed in the copper sulfate electrolyte solution at the same time. Turn on the power and set the parameters to a current density of 0.00075mm 2 / A, the voltage is 3V, and the power-on time is 30min. After the power-on is completed, the copper sheet will produce a microscopic appearance of micro-nano level unevenness. Then use an ultrasonic cleaner (parameter setting temperature 25°C)...

Embodiment 2

[0038] To prepare a durable superhydrophobic candle soot coating, the specific steps are as follows:

[0039] Step 1): Immerse a 2cm×2cm×0.25cm copper sheet and a stainless steel sheet with a purity of 99.99% in a 95% ethanol solution, and clean it with an ultrasonic cleaner (set at 25°C) for 10 minutes to remove impurities on the surface of the substrate and grease. The copper piece is connected to the anode of the power supply, the stainless steel piece is connected to the cathode of the power supply, and the copper piece and the stainless steel piece are immersed in the copper sulfate electrolyte solution at the same time. Turn on the power and set the parameters to a current density of 0.00060mm 2 / A, the voltage is 3V, and the power-on time is 30min. After the power-on is over, the copper sheet will produce a micro-nano-level uneven texture. Then use an ultrasonic cleaner (parameter setting temperature 25° C.) with 95% ethanol as a cleaning solvent to clean the chemical...

Embodiment 3

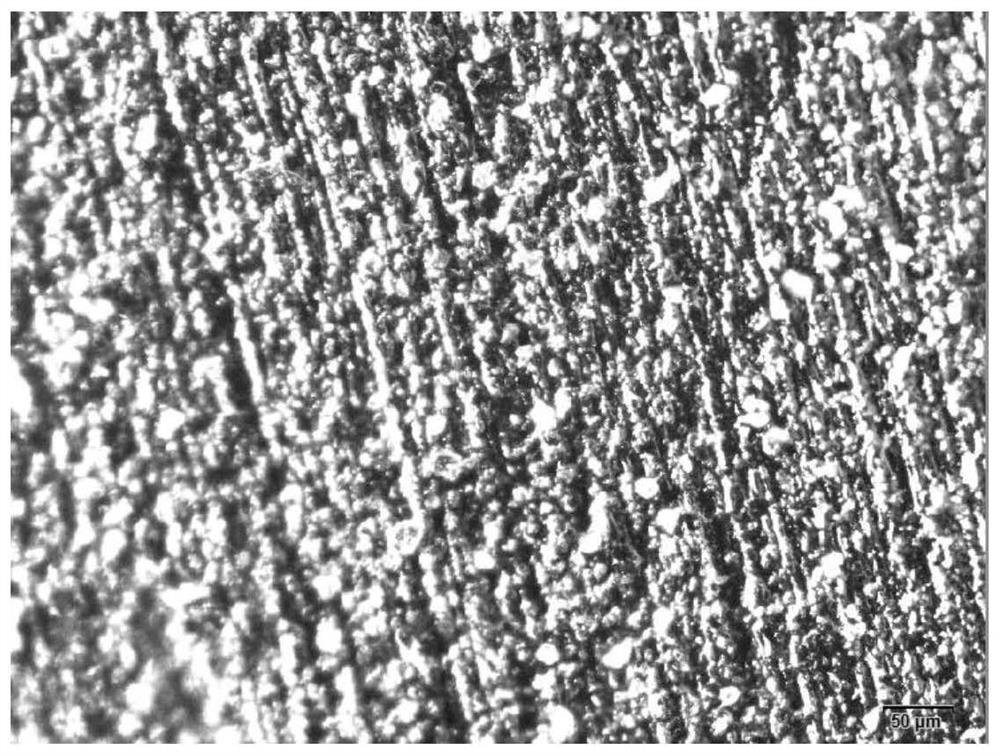

[0048] To prepare a durable superhydrophobic candle soot coating, the specific steps are as follows:

[0049] Step 1): immerse 2cm×2cm×0.25cm copper and zinc sheets with a purity of 99.99% in 95% ethanol solution, and clean them with an ultrasonic cleaner (temperature set at 25°C) for 10 minutes to remove impurities on the surface of the substrate and grease. The zinc piece is connected to the anode of the power supply, and the copper piece is connected to the cathode of the power supply, and the copper piece and the zinc piece are immersed in the dilute sulfuric acid electrolyte solution at the same time. Turn on the power and set the parameters to a current density of 0.00075mm 2 / A, the voltage is 3V, and the energization time is 30min. After the energization is over, the zinc sheet will produce a microscopic appearance of micro-nano level unevenness. Then use an ultrasonic cleaner (parameter setting temperature 25° C.) and use 95% ethanol as a cleaning solvent to clean t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com