Method for synthesizing star block copolymer based on combination of active anionic polymerization and hydrosilylation click reaction

A block copolymer and living anion technology, applied in the field of living anion polymerization, can solve the problems that are not conducive to the precise regulation of polymer composition and distribution, cumbersome synthesis methods, and complicated processing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

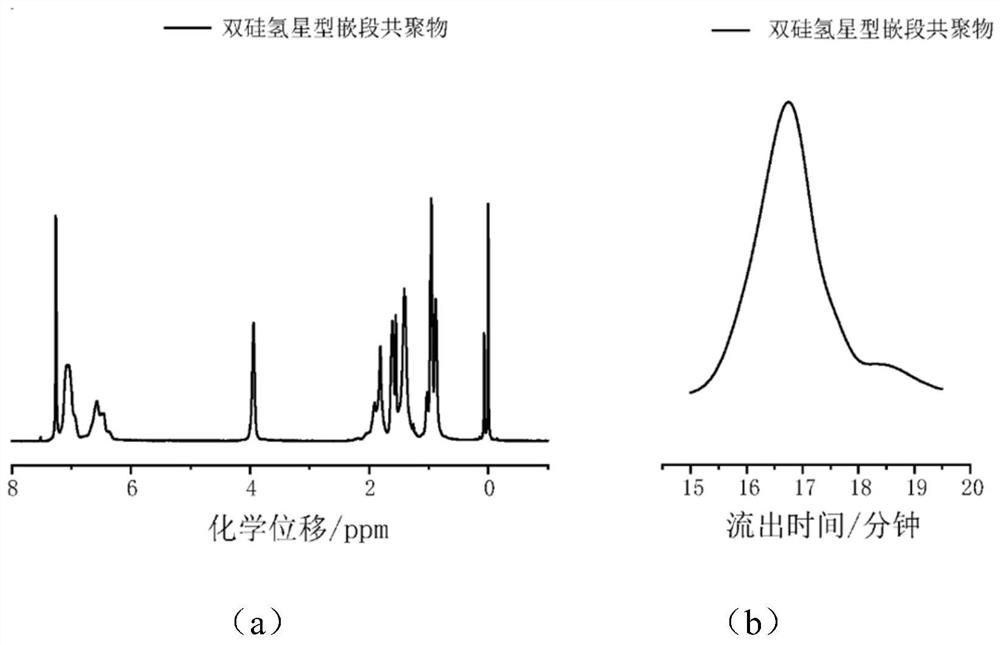

[0039] Using living anionic polymerization combined with hydrosilylation click reaction, the molecular weight of polystyrene is designed to be 6.0×10 4 The molecular weight of g / mol poly-n-butyl methacrylate is designed to be 3.0×10 4 g / mol. The whole process of polystyrene polymerization in this experiment was completed in a glove box protected by argon atmosphere, and the polymerization of polymethyl methacrylate n-butyl ester was carried out under the condition of isolating water and oxygen at -78 ℃. Before the experiment, a certain amount of monomer DPE-2SiH needs to be mixed Prepare for dilution.

[0040] The first step: at 20°C, add (1g, 9.60mmol) styrene and 9g of solvent benzene into a 20mL polymerization bottle, shake slightly for 2min to make it fully mixed, and then quickly inject sec-BuLi (430μl 0.04651mol / L ) to initiate the polymerization of the monomer and shake to make it evenly initiated, and the reaction solution is orange-yellow. After 6 h, quantitative D...

Embodiment 2

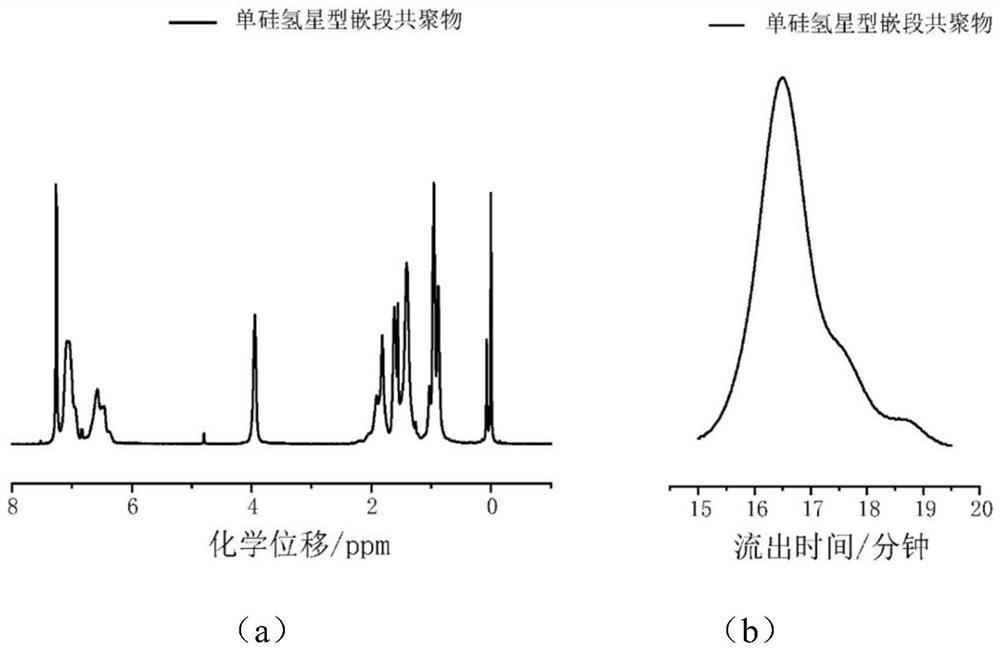

[0044] Using living anionic polymerization combined with hydrosilylation click reaction, the molecular weight of polystyrene is designed to be 6.0×10 4 The molecular weight of g / mol poly(n-butyl methacrylate) is designed to be 6.0×10 4 g / mol. The whole process of polystyrene polymerization in this experiment was completed in a glove box protected by argon atmosphere, and the polymerization of poly-n-butyl methacrylate was carried out under the condition of isolating water and oxygen at -78 °C. Before the experiment, a certain amount of monomer DPE-SiH Prepare for dilution.

[0045] The first step: at 20°C, add (0.5g, 4.81mmol) 18ml of styrene solvent benzene into a 20mL polymerization bottle, shake slightly for 2min to make it well mixed, and then quickly inject sec-BuLi (358μl 0.04651mol / L ) to initiate the polymerization of the monomer and shake to make it evenly initiated, and the reaction solution is orange-yellow. After 3h, quantitative DPE-SiH (1.67×10) was rapidly ad...

Embodiment 3

[0049] Using living anionic polymerization combined with hydrosilylation click reaction, the molecular weight of polystyrene is designed to be 6.0×10 4 The molecular weight of g / mol poly-n-butyl methacrylate is designed to be 3.0×10 4 g / mol. The whole process of polystyrene polymerization in this experiment was completed in a glove box protected by an argon atmosphere, and the polymethacrylic acid polymerization was carried out under the condition of isolating water and oxygen at -78 °C. Before the experiment, a certain amount of monomer DPE-2SiH needs to be diluted for use. .

[0050] The first step: at 25°C, add (1g, 9.60mmol) styrene and 9g of solvent benzene into a 20mL polymerization bottle, shake slightly for 2min to make it fully mixed, and then quickly inject sec-BuLi (430μl 0.04651mol / L ) to initiate the polymerization of the monomer and shake to make it evenly initiated, and the reaction solution is orange-yellow. After 6 h, quantitative DPE-2SiH (1.9×10) was rapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com