High-sensitivity flexible pressure sensing material in pure water and application thereof

A high-sensitivity, sensing material technology, applied in the field of high-sensitivity flexible pressure sensing materials, can solve the problem of lack of clear micro-engineering methods, and achieve the effects of good adjustability, high sensitivity and stability, and high pressure response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

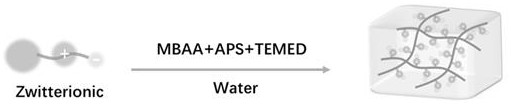

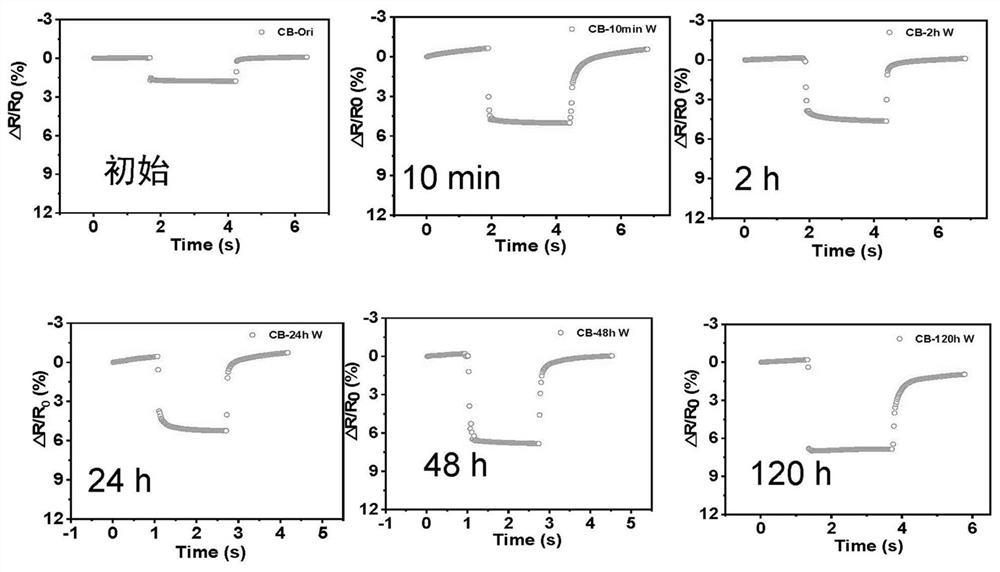

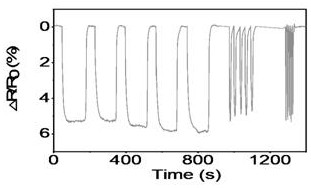

[0027] figure 1 A schematic diagram showing the polymerization of alkenyl monomers containing zwitterions to form a hydrogel; specifically, the following steps are included: (1) adding 3-[[2-(methacryloyloxy)ethyl]dimethylammonium]propane Ester (carboxybetaine) (4.2 g) was dissolved in water (12 mL), sonicated to dissolve completely, then methylenebisacrylamide (cross-linking agent) (0.0125 g) was added, sonicated to dissolve, and finally added Ammonium sulfate (thermal initiator) (0.02g) and tetramethylethylenediamine (accelerator) (0.0155g, 20μL) were stirred thoroughly to obtain a pre-reaction solution. Add the pre-reaction solution between two slides separated by a 2 mm thick PDMS spacer. Polymerization was then carried out at 60°C for 6 hours to ensure sufficient reaction. After the reaction, the hydrogel was peeled off from the glass slide and soaked in pure water, and the pure water was replaced every day for 5 days to remove unreacted chemicals and reagents to obtain...

Embodiment 2

[0030] (1) Dissolve 3-[[2-(methacryloyloxy)ethyl]dimethylammonium]propionate (carboxybetaine) (4.2 g) in water (12 mL), and ultrasonically make it completely Dissolved, followed by addition of methylenebisacrylamide (crosslinker) (0.025 g), sonicated for dissolution, and finally ammonium persulfate (thermal initiator) (0.02 g) and tetramethylethylenediamine (accelerator) (20 μL), and stir well to obtain the pre-reaction solution. Add the pre-reaction solution between two slides separated by a 2 mm thick PDMS spacer. Polymerization was then carried out at 60°C for 6 hours to ensure sufficient reaction. After the reaction, the hydrogel was peeled off from the glass slide and soaked in pure water, and the pure water was replaced every day for 5 days to remove unreacted chemicals and reagents to obtain a highly sensitive flexible pressure sensor with swelling balance. Sensitive material.

[0031] The setting parameters of digital bridge LCR are: test frequency 100 kHz, test lev...

Embodiment 3

[0033] Dissolve 3-[[2-(methacryloyloxy)ethyl]dimethylammonium]propionate (carboxybetaine) (4.2 g) in water (12 mL), sonicate to dissolve completely, and then Add methylenebisacrylamide (crosslinker) (0.05 g), dissolve by ultrasonication, and finally add ammonium persulfate (thermal initiator) (0.02 g) and tetramethylethylenediamine (accelerator) (20 μL), The pre-reaction solution is obtained after fully stirring evenly. Add the pre-reaction solution between two slides separated by a 2 mm thick PDMS spacer. Polymerization was then carried out at 60°C for 6 hours to ensure sufficient reaction. After the reaction, the hydrogel was peeled off from the glass slide and soaked in pure water, and the pure water was replaced every day for 5 days to remove unreacted chemicals and reagents to obtain a highly sensitive flexible pressure sensor with swelling balance. Sensitive material.

[0034] The setting parameters of digital bridge LCR are: test frequency 100 kHz, test level 2 V. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com