Oil-resistant conductive fluororubber, and preparation method and application thereof

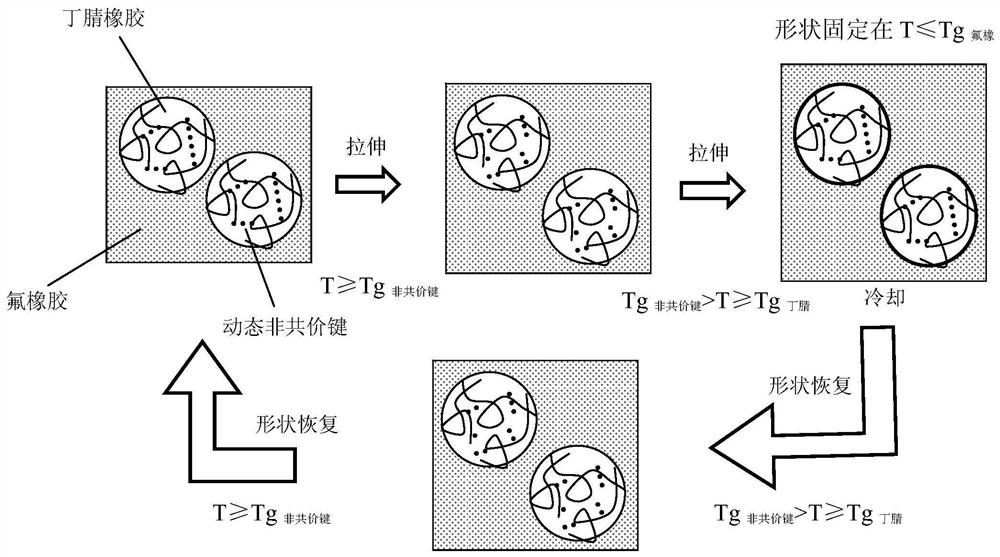

A fluororubber and oil-resistant technology, which is applied in the field of oil-resistant and conductive fluororubber, can solve problems such as difficult preparation of shape memory materials, achieve the effects of improving shape fixation rate and shape recovery, improving mixing effect, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of a kind of oil-resistant conductive fluororubber of the present invention is as follows:

[0040] (1) Prepare fluororubber compound rubber according to the following formula: 100 parts of fluororubber, 1 to 3 parts of fluororubber vulcanizing agent, 0.1 to 0.8 parts of fluororubber accelerator, 1 to 5 parts of fluororubber acid absorber;

[0041](2) Prepare the nitrile rubber compound according to the following formula: 100 parts of nitrile rubber, 0.5-3 parts of sulfur, 0.5-3 parts of vulcanization accelerator, 30-40 parts of coordination salt, and 1-5 parts of anti-aging agent.

[0042] (3) The nitrile rubber compound is frozen and ground into powder, sieved, mixed evenly with 1 to 4 parts of carbon nanotubes, and then mixed and vulcanized with the fluorine rubber compound; the quality of the fluorine rubber compound: The mass of nitrile rubber-carbon nanotube mixed powder is 9:1~6:4.

[0043] In an optional embodiment, the fluorine rubber in...

Embodiment 1

[0061] In this embodiment, the preparation method of oil-resistant conductive fluororubber comprises the following steps:

[0062] (1) Prepare the nitrile rubber compound according to the following formula:

[0063] Nitrile rubber (Zhenjiang Nandi 1052) 100g;

[0064] Sulfur 1.5g;

[0065] Vulcanization accelerator DM 0.5g;

[0067] Anti-aging agent MB 1g;

[0068] Anti-aging agent RD 2g.

[0069] The specific steps are as follows: zinc chloride and acetone are prepared into an organic solution with a concentration of 51 wt%, and are uniformly mixed by ultrasonic;

[0070] Plasticize nitrile rubber at room temperature, then raise the temperature to 90°C, add zinc chloride solution dropwise on the rubber, knead on an open mill, cool to room temperature after volatilizing the acetone, and weigh other Raw materials are mixed on the open mill;

[0071] (2) the acrylonitrile-butadiene rubber compound in the step (1) is used with a frozen mill to g...

Embodiment 2

[0083] The preparation method of the oil-resistant conductive fluororubber of the present embodiment comprises the following steps:

[0084] (1) Prepare the nitrile rubber compound according to the following formula:

[0085] Hydrogenated nitrile rubber (Zion 2210) 100g;

[0086] Sulfur 1.5g;

[0087] Vulcanization accelerator D 0.5g;

[0088] Ferric chloride 40g;

[0089] Anti-aging agent MB 3g;

[0090] Antiaging agent RD 1g.

[0091] The specific steps are: preparing ferric chloride and acetone into an organic solution with a concentration of 60 wt%, and mixing them uniformly through ultrasonic;

[0092] Plasticize the hydrogenated nitrile rubber at room temperature, then raise the temperature to 95°C, add the ferric chloride solution onto the rubber, and knead on the open mill. After volatilizing the acetone, cool to room temperature, and weigh Other raw materials are mixed on the open mill;

[0093] (2) The hydrogenated nitrile butadiene rubber compound in step (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com