Anti-EMI super-junction VDMOS device and preparation method thereof

A device and conductive type technology, applied in the field of anti-EMI superjunction VDMOS devices and preparation, can solve the problems of electromagnetic pollution of components and equipment, parasitic transistor turn-on, fast switching speed, etc., to reduce EMI electromagnetic radiation noise, reduce switching The effect of shock and endurance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

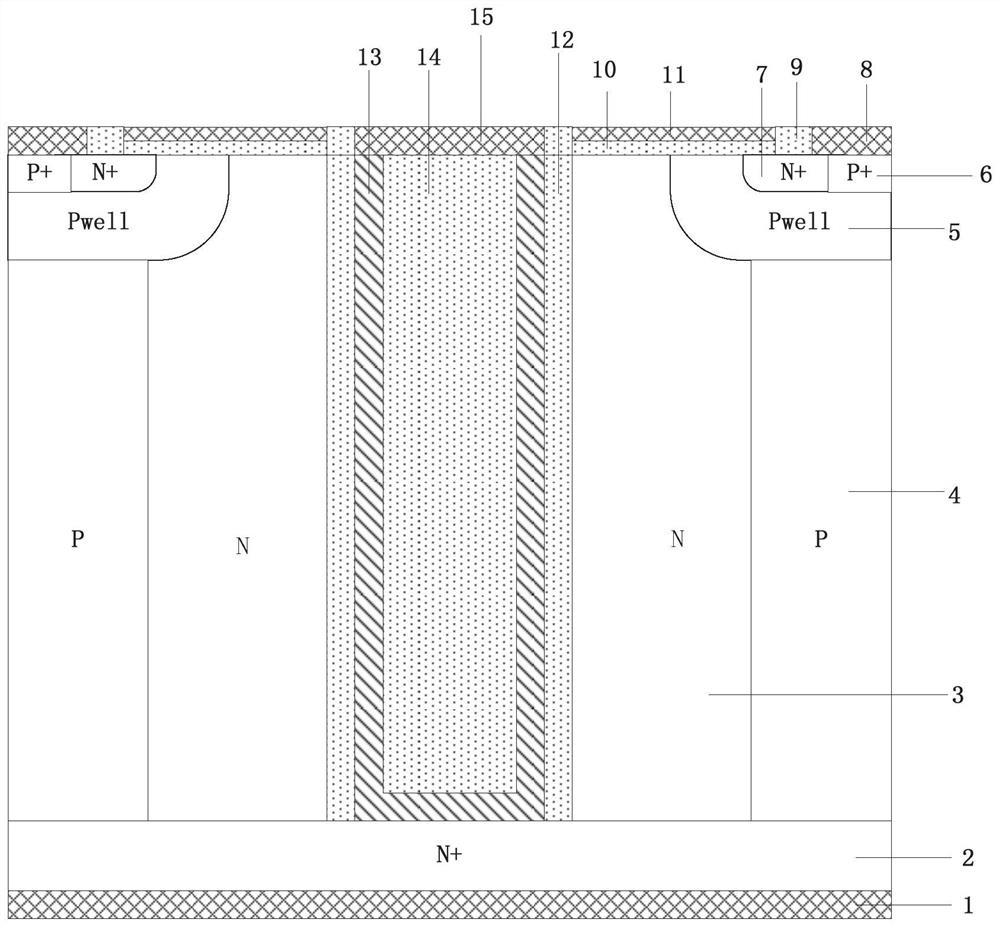

[0053] like figure 1 As shown, Embodiment 1 of the present invention provides a kind of anti-EMI super junction VDMOS device, comprising:

[0054] Drain Metal 1;

[0055] a substrate 2 of the first conductivity type located above the drain metal 1;

[0056] A super junction drift region located above the substrate 2 of the first conductivity type, the super junction drift region includes a drift region 3 of the first conductivity type and a drift region 4 of the second conductivity type;

[0057] The second conductivity type base region 5 located on the upper part of the superjunction drift region;

[0058] The second conductivity type ohmic contact region 6 and the first conductivity type source region 7 located inside the second conductivity type base region 5;

[0059] a gate oxide layer 10 located above the base region 5 of the second conductivity type;

[0060] a gate 11 located above the gate oxide layer 10;

[0061] The source metal 8 located above the second condu...

Embodiment 2

[0069] Embodiment 2 of the present invention provides a method for preparing an anti-EMI super junction VDMOS device, including the following process:

[0070] Take the semiconductor substrate material of the first conductivity type;

[0071] Epitaxially form the drift region of the super junction structure on the substrate material;

[0072] Etching a trench in the super junction drift region, the trench runs through the entire super junction drift region to the first conductivity type substrate;

[0073] growing an oxide layer dielectric on the sidewall of the trench;

[0074] Depositing and forming a U-shaped semi-insulating polysilicon layer in the trench;

[0075] Depositing an oxide layer dielectric in the U-shaped semi-insulating polysilicon layer;

[0076] growing a gate oxide over the drift region;

[0077] Depositing a polysilicon gate over the gate oxide;

[0078] Ion implantation in the upper part of the drift region and push the junction to form the base regi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com