Flame-retardant glass fiber composite material and preparation method thereof

A technology of glass fiber and composite materials, which is applied in the field of flame-retardant glass fiber composite materials, and can solve the problems of loose glass fiber structure, glass fiber elastic modulus, reduction of hardness and chemical stability, and easy fracture of glass fiber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

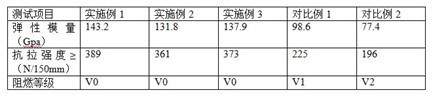

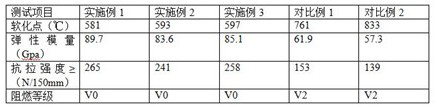

Examples

Embodiment 1

[0020] A kind of fire-retardant glass fiber composite material, raw material comprises glass fiber composition and epoxy resin substrate glue solution, and described glass fiber composition is mainly made up of the raw material of following weight parts: SiO 2 60 parts, γ-Al 2 o 3 8 parts, CaO12 parts, MgO10 parts, B 2 o 3 3 copies, Li 2 O0.2 parts, Na 2 O1.2 parts, Sb 2 o 3 0.02 parts and 0.3 parts of Co powder; 110 parts of the epoxy resin, 22 parts of silica nanoparticles, 12 parts of hexahydrophthalic anhydride, 12 parts of polyacrylamide, 2 parts of carboxymethyl cellulose, and nanometer CaCO31. 3 parts and 7 parts aluminum hydroxide.

[0021]The γ-Al 2 o 3 The particle size is 10-25nm, and the specific surface area is ≥300m 2 / g, the Li 2 O, Na 2 O, Sb 2 o 3 and Co powder particle size are smaller than γ-Al 2 o 3 particle size.

[0022] The mixing method of described glass fiber composition comprises the steps:

[0023] (1) Weigh the raw materials ac...

Embodiment 2

[0028] A flame-retardant glass fiber composite material, raw materials include a glass fiber composition and an epoxy resin substrate glue, the weight ratio of the glass fiber composition to the epoxy resin substrate glue is 7:3; the glass The fiber composition is mainly composed of the following raw materials in parts by weight: SiO 2 58 parts, γ-Al 2 o 3 5 parts, CaO8 parts, MgO8 parts, B 2 o 3 2 copies, Li 2 O0.1 parts, Na 2 O0.5 parts, Sb 2 o 3 0.01 part and 0.1 part of Co powder; the epoxy resin substrate glue mainly consists of the following raw materials in parts by weight: 100 parts of epoxy resin, 20 parts of silica nanoparticles, 5 parts of hexahydrophthalic anhydride, 5 parts of polyacrylamide, 1 part of carboxymethyl cellulose, nano-CaCO 3 0.5 parts and 5 parts of aluminum hydroxide.

[0029] The γ-Al 2 o 3 The particle size is 10-25nm, and the specific surface area is ≥300m 2 / g, the Li 2 O, Na 2 O, Sb 2 o 3 and Co powder particle size are small...

Embodiment 3

[0036] A flame-retardant glass fiber composite material, raw materials include a glass fiber composition and an epoxy resin substrate glue, the weight ratio of the glass fiber composition to the epoxy resin substrate glue is 7:3.5; the glass The fiber composition is mainly composed of the following raw materials in parts by weight: SiO 2 65 parts, γ-Al 2 o 3 10 parts, CaO16 parts, MgO13 parts, B 2 o 3 5 copies, Li 2 O0.3 parts, Na 2 O2 parts, Sb 2 o 3 0.03 part and 0.5 part of Co powder; the epoxy resin substrate glue mainly consists of the following raw materials in parts by weight: 120 parts of epoxy resin, 25 parts of silica nanoparticles, 10 parts of hexahydrophthalic anhydride, 10 parts of polyacrylamide, 3 parts of carboxymethyl cellulose, nano-CaCO 3 2 parts and 10 parts of aluminum hydroxide.

[0037] The γ-Al 2 o 3 The particle size is 10-25nm, and the specific surface area is ≥300m 2 / g, the Li 2 O, Na 2 O, Sb 2 o 3 and Co powder particle size are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com