Preparation method of heptafluoroisobutyronitrile

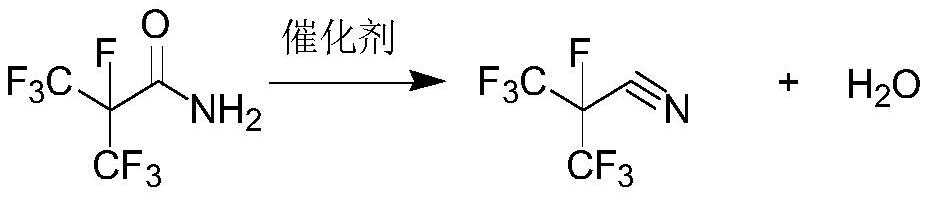

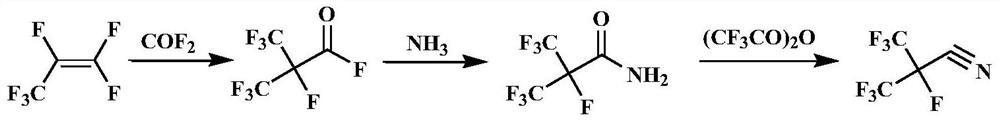

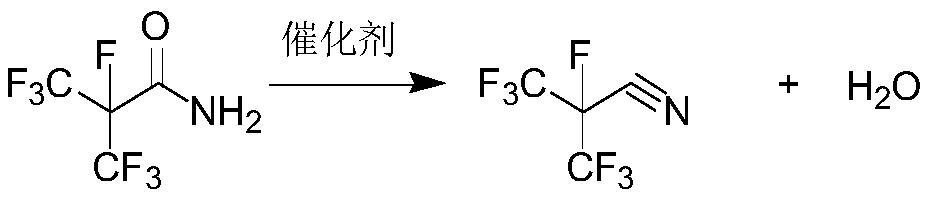

A technology of heptafluoroisobutyronitrile and heptafluoroisobutyramide, which is applied to the purification/separation of carboxylic acid nitriles, organic chemistry, etc., can solve the problems of easy deactivation of catalysts, low reaction yield, harmful environment, etc., and achieve improved product quality. Selectivity, simple preparation process, no effects of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 3A molecular sieves were calcined at 300°C for 4 hours under the protection of nitrogen, and 100g of 3A molecular sieves were loaded into a tubular reactor, and heptafluoroisobutyramide (213g, 1mol) was heated in a preheater, preheated to 160°C, and put into a tubular reactor. In the reactor, the reaction temperature is 200°C, the residence time is 30s, the reaction pressure is 0.05MPa, and the material flow rate is 0.2m / s. Heptafluoroisobutyronitrile was collected and tested: the purity of heptafluoroisobutyronitrile was 99.0%, and the yield was 93.2%.

Embodiment 2

[0034] The 5A molecular sieve was roasted at 300°C for 4 hours under the protection of nitrogen, and 100g of 5A molecular sieve was loaded into the tubular reactor. Heptafluoroisobutyramide (213g, 1mol) was heated in the preheater, preheated to 160°C, and entered into the tubular reaction device, the reaction temperature is 200°C, the residence time is 30s, the reaction pressure is 0.05MPa, and the material flow rate is 0.2m / s. Heptafluoroisobutyronitrile was collected and tested: the purity of heptafluoroisobutyronitrile was 98.7%, and the yield was 90.1%.

Embodiment 3

[0036] The β molecular sieve was roasted at 300°C for 4 hours under the protection of nitrogen, and 100g of the β molecular sieve was loaded into the tubular reactor, and heptafluoroisobutyramide (213g, 1mol) was sent to the preheater for heating, preheated to 160°C, and entered into the tubular reaction device, the reaction temperature is 200°C, the residence time is 30s, the reaction pressure is 0.05MPa, and the material flow rate is 0.2m / s. Heptafluoroisobutyronitrile was collected and tested: the purity of heptafluoroisobutyronitrile was 98.2%, and the yield was 92.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com