Preparation method of polystyrene foaming nucleating agent master batch and foaming polystyrene using nucleating agent master batch

A technology of polystyrene foaming and nucleating agent masterbatch, which is applied in the field of expanded polystyrene, which can solve the problems of uneven dispersion of nucleating agents, agglomeration and unevenness of nucleating agents, and facilitate in-situ polymerization , Improve the foaming effect and improve the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

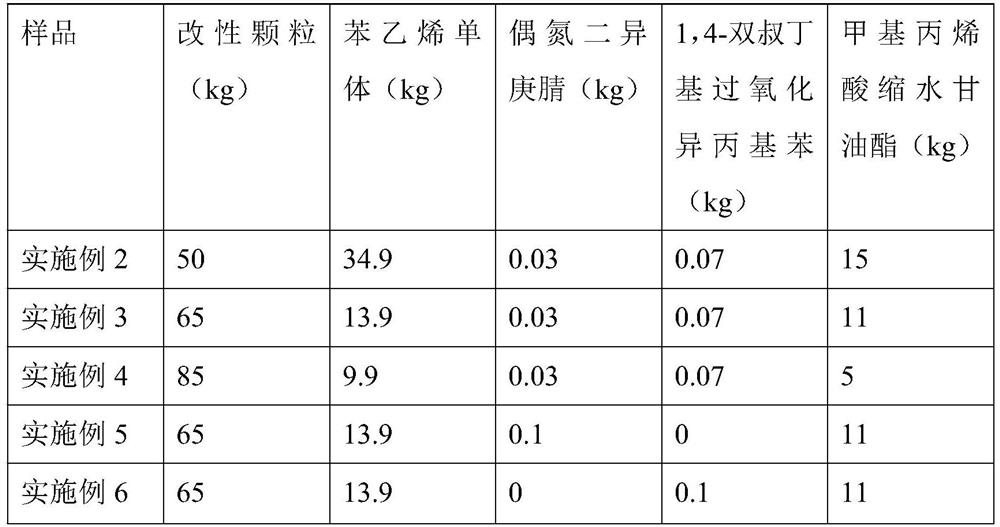

[0032] This embodiment provides a method for preparing polystyrene foaming nucleating agent masterbatch, the preparation method comprising the following steps:

[0033] Through the powder wet surface modification method, the surface treatment agent is used to modify the surface of the inorganic particles to obtain modified particles;

[0034] First, add the modified particles, styrene monomer, initiator and comonomer into the prepolymerization device, and under the protection of inert gas, first stir evenly at room temperature, then raise the temperature to 50-160°C, and then stir for 30- 60min, obtain the prepolymer of styrene;

[0035] The styrene prepolymer is added into an extruder to carry out in-situ polymerization reaction to obtain the polystyrene foaming nucleating agent master batch.

[0036] For the inorganic particles mentioned in the preparation method of the polystyrene foaming nucleating agent masterbatch of the present embodiment, inorganic micro-nano particle...

preparation example

[0048] The detection method of grafting rate of modified particles:

[0049] Take 2 grams of modified particles, wash its surface repeatedly with a mixed solvent of 90% ethanol and 10% water in the total weight ratio, remove unreacted coupling agent, dry it, and weigh it W1, and then carry out muffle furnace calcination, remove the coated coupling agent, weigh again as W2, the grafting rate of coupling agent

preparation example 1

[0051] Stir the γ-aminopropyltriethoxysilane that accounts for 20% of the total weight ratio, the ethanol that accounts for 72% of the total weight ratio, and the water that accounts for 8% of the total weight ratio to form a transparent coupling agent stock solution . Add silicon dioxide with an average particle size of 65 nanometers into a high-speed mixer, and slowly spray a coupling agent stock solution accounting for 7.5% by weight of silicon dioxide on the stirring silicon dioxide during stirring. After adding the stock solution of the coupling agent, the material was stirred in a high-speed mixer for another half an hour, and then dried at 120° C. for 2 hours to obtain modified particles. The grafting rate of the modified particles is 1.28%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com