Surface treatment method of steel wire for needle bearing

A surface treatment, needle roller bearing technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as poor lubrication, achieve good lubrication effect, solve poor lubrication, and bond firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

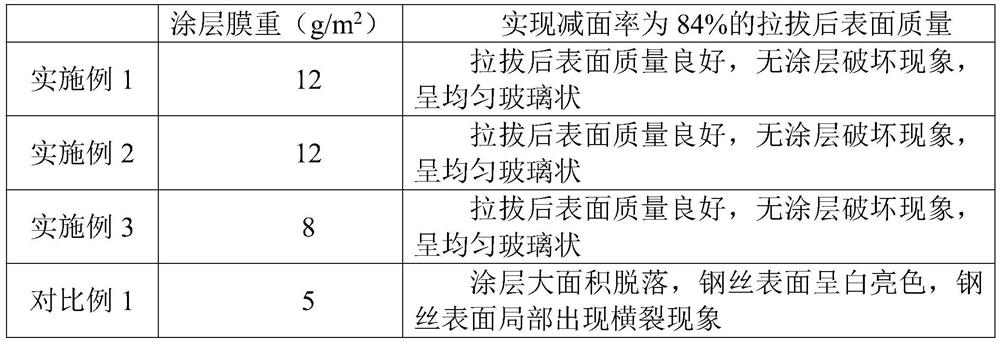

Examples

Embodiment 1

[0051] A surface treatment method for steel wires for needle bearings, comprising the following steps: pickling-rinsing-neutralization-coating-drying; specifically:

[0052] 1) Immerse the steel wire in a hydrochloric acid solution with a temperature of 40-50°C and a concentration of 120-200g / L for 30-60 minutes to remove the oxidized substances on the surface;

[0053] 2) Then use 0.75-1.2MPa high-pressure water to wash off the acid attached to the surface of the material;

[0054] 3) neutralize with 0.5-2wt% NaOH solution for 30-60s;

[0055] 4) Soak the steel wire treated in step 3) in the coating solution for 3 minutes, and the temperature of the coating solution is 90-100° C.;

[0056] 5) Dry the steel wire in a drying tank at 120-150°C for 10-15 minutes;

[0057] The mass percentage composition of the coating solution that adopts in the coating process is as follows:

[0058] Borax Na 2 B 4 o 7 .10H 2 O: 20%;

[0059] Trisodium phosphate dodecahydrate: 2%;

[00...

Embodiment 2

[0068] A surface treatment method for steel wires for needle bearings, comprising the following steps: pickling-rinsing-neutralization-coating-drying; specifically:

[0069] 1) Immerse the steel wire in a hydrochloric acid solution with a temperature of 40-50°C and a concentration of 120-200g / L for 30-60 minutes to remove the oxidized substances on the surface;

[0070] 2) Then use 0.75-1.2MPa high-pressure water to wash off the acid attached to the surface of the material;

[0071] 3) neutralize with 0.5-2wt% NaOH solution for 30-60s;

[0072] 4) Soak the steel wire treated in step 3) in the coating solution for 3 minutes, and the temperature of the coating solution is 90-100° C.;

[0073] 5) Dry the steel wire in a drying tank at 120-150°C for 10-15 minutes;

[0074] The mass percentage composition of the coating solution that adopts in the coating process is as follows:

[0075] Borax Na 2 B 4 o 7 .10H 2 O: 20%;

[0076] Trisodium phosphate dodecahydrate: 2%;

[00...

Embodiment 3

[0085] A surface treatment method for steel wires for needle bearings, comprising the following steps: pickling-rinsing-neutralization-coating-drying; specifically:

[0086] 1) Immerse the steel wire in a hydrochloric acid solution with a temperature of 40-50°C and a concentration of 120-200g / L for 30-60 minutes to remove the oxidized substances on the surface;

[0087] 2) Then use 0.75-1.2MPa high-pressure water to wash off the acid attached to the surface of the material;

[0088] 3) neutralize with 0.5-2wt% NaOH solution for 30-60s;

[0089] 4) Soak the steel wire treated in step 3) in the coating solution for 3 minutes, and the temperature of the coating solution is 90-100° C.;

[0090] 5) Dry the steel wire in a drying tank at 120-150°C for 10-15 minutes;

[0091] The mass percentage composition of the coating solution that adopts in the coating process is as follows:

[0092] Borax Na 2 B 4 o 7 .10H 2 O: 15%;

[0093] Trisodium phosphate dodecahydrate: 1.5%;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com