Surface modified polytetrafluoroethylene fiber membrane and preparation method thereof

A polytetrafluoroethylene, surface modification technology, applied in the direction of fiber type, fiber treatment, biochemical fiber treatment, etc., can solve the problems of prosthesis failure, obstructive thrombus, and failure to achieve adhesion, so as to promote proliferation and promote Effect of endothelialization and accelerated adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

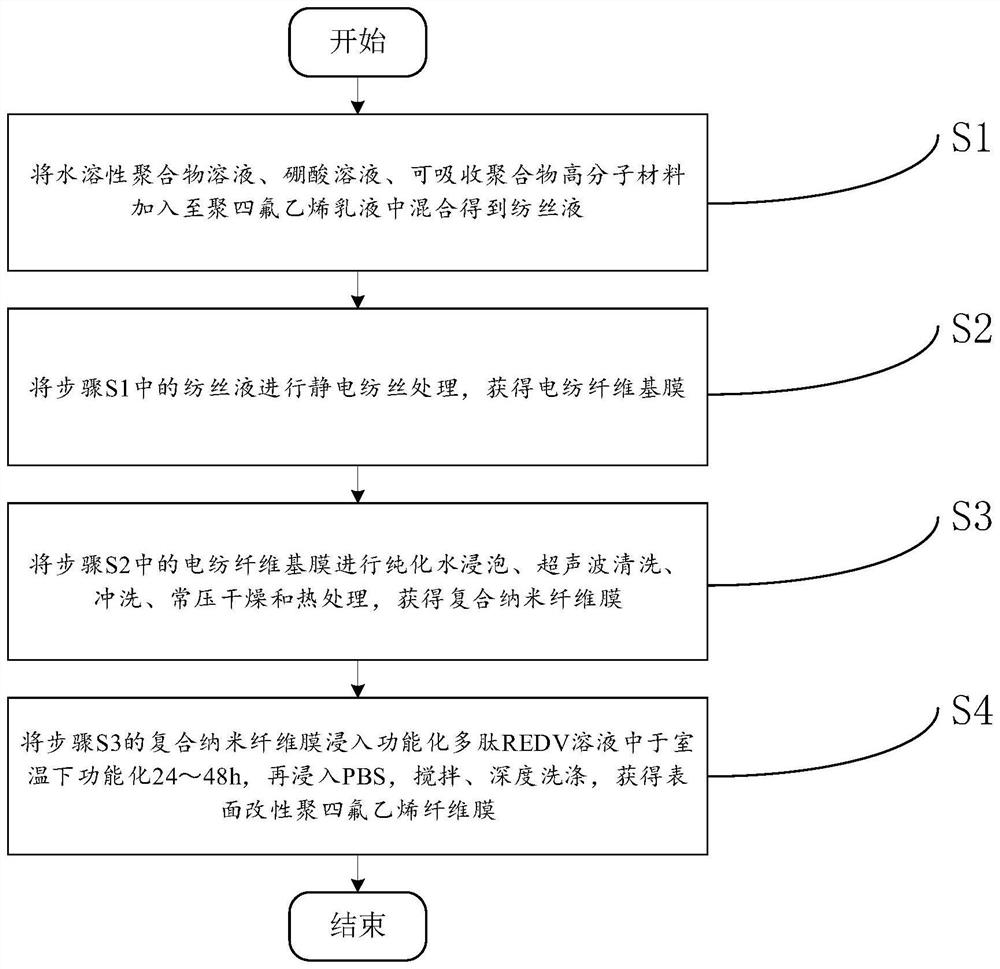

[0025] The preparation method of the surface-modified polytetrafluoroethylene fiber membrane provided by this embodiment, the specific technical scheme is as follows:

[0026] (1) Preparation of composite nanofiber membrane:

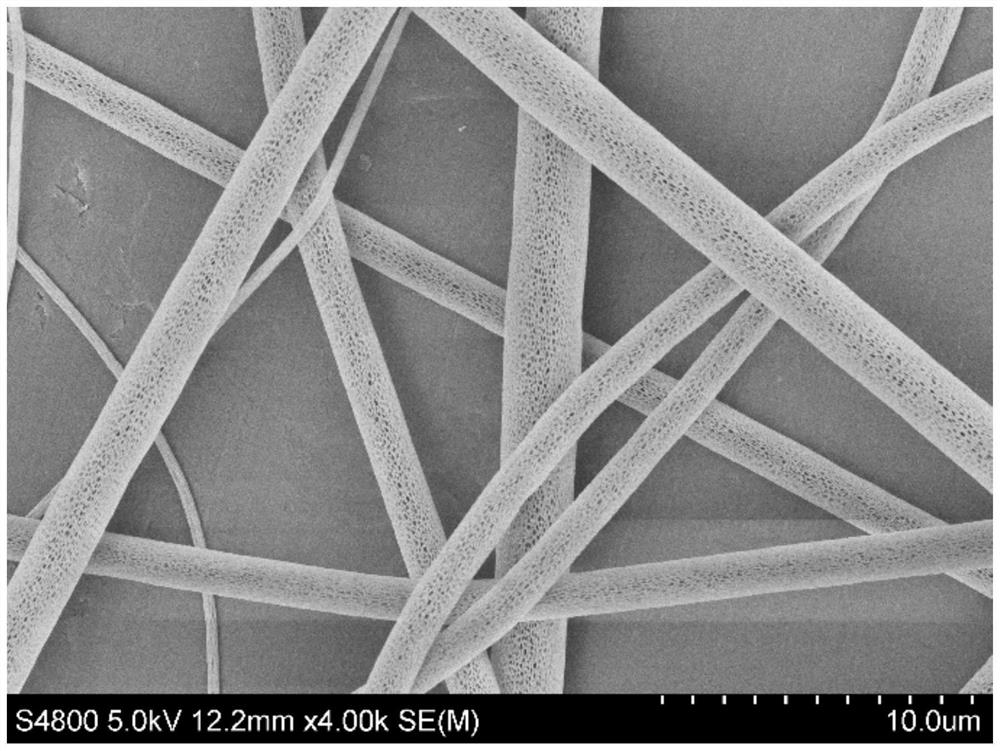

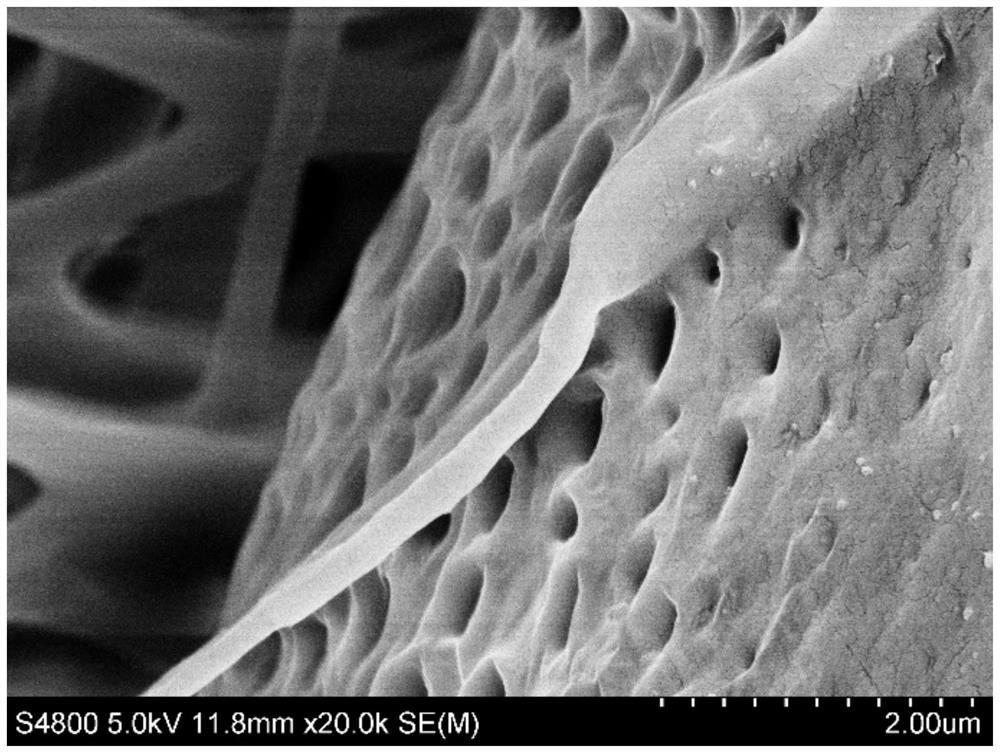

[0027] 4 mL of 5% PVA solution, 20 μL of 10% boric acid solution and 2 g of PLGA were added to 50 mL of 40% PTFE emulsion, mixed, and stirred at room temperature for 24 hours to obtain a spinning solution. The spinning solution was transferred to a 30mL syringe with a needle of 0.6cm to start high-voltage electrospinning, the spinning voltage was set to 40kV, the distance from the syringe needle to the receiving drum was 30cm, the ambient temperature was controlled at 22°C, and the humidity was 45%. After spinning, the electrospun fiber base film is taken out from the drum. Soak the electrospun fiber base membrane in a container filled with purified water for 6 hours, then ultrasonically clean it for 20 minutes, rinse it with ethanol three times, and fi...

Embodiment 2

[0032] The present embodiment provides the preparation method of surface modified polytetrafluoroethylene fiber membrane, and specific technical scheme is as follows:

[0033] (1) Preparation of composite nanofiber membrane:

[0034] Add 10 mL of 10% PVA solution, 160 μL of 5% boric acid solution and 2 g of PLGA into 60% and 50 mL of PTFE emulsion, mix and stir at room temperature for 24 hours to obtain a spinning solution. The spinning solution was transferred to a 30mL syringe with a needle of 0.8cm to start high-voltage electrospinning, the spinning voltage was set to 30kV, the distance from the syringe needle to the receiving drum was 20cm, the ambient temperature was controlled at 20°C, and the humidity was 40%. After spinning, the electrospun fiber base film is taken out from the drum. Soak the electrospun fiber base membrane in a container filled with purified water for 6 hours, then ultrasonically clean it for 10 minutes, rinse it with ethanol three times, and finally...

Embodiment 3

[0039] The present embodiment provides the preparation method of surface modified polytetrafluoroethylene fiber membrane, and specific technical scheme is as follows:

[0040] (1) Preparation of composite nanofiber membrane:

[0041] Add 2 mL of 15% PVA solution, 200 μL of 2% boric acid solution and 2 g of PLGA into 80% and 12.5 mL of PTFE emulsion, mix and stir at room temperature for 24 hours to obtain a spinning solution. The spinning solution was transferred to a 30mL syringe with a needle of 0.6cm to start high-voltage electrospinning, the spinning voltage was set to 40kV, the distance from the syringe needle to the receiving drum was 30cm, the ambient temperature was controlled at 22°C, and the humidity was 45%. After spinning, the electrospun fiber base film is taken out from the drum. Soak the electrospun fiber base membrane in a container filled with purified water for 6 hours, then ultrasonically clean it for 3 minutes, rinse it with ethanol for 3 times, and finally d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compression modulus | aaaaa | aaaaa |

| Maximum stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com