Membrane electrode catalyst layer with gradient pore structure as well as preparation method and application of membrane electrode catalyst layer

A technology of catalytic layer and gradient hole, which is applied in the field of membrane electrode catalytic layer with gradient pore structure and its preparation, can solve the problems of hindering electron conduction, blocking, weakening battery performance, etc., and achieve the effect of reducing the cost of membrane electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

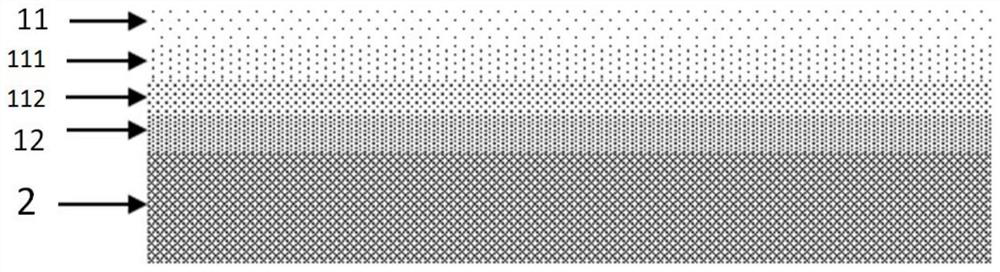

[0047] The preparation method of the membrane electrode catalytic layer with gradient pore structure comprises the following steps:

[0048] Preparation of the small hole catalyst layer slurry: Mix the small catalyst, perfluorosulfonic acid resin solution, low boiling point solvent and deionized water evenly to obtain the small hole layer catalyst layer slurry;

[0049] Preparation of transition layer catalytic layer slurry: uniformly mix small catalyst, large catalyst, perfluorosulfonic acid resin solution, low boiling point solvent and deionized water to obtain transition layer catalytic layer slurry; in the transition layer catalytic layer slurry, the In the transition layer catalytic layer slurry, the mass of the large catalyst accounts for 10-90% of the mass of the transition layer, and the mass of the small catalyst accounts for 10-90% of the mass of the transition layer.

[0050] Preparation of macroporous layer catalyst layer slurry: mix macrocatalyst, perfluorosulfoni...

Embodiment 1

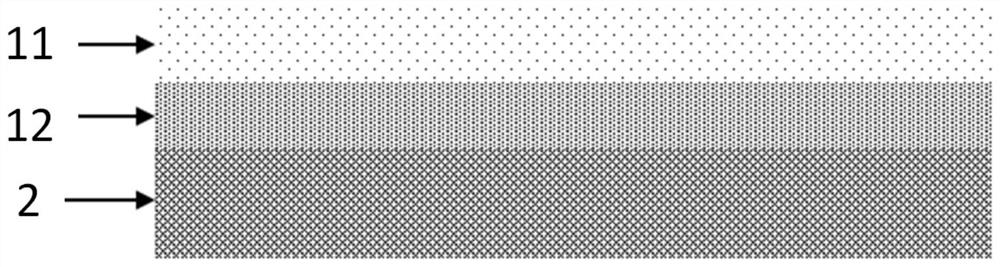

[0055] A method for preparing a catalytic layer with a large and small two-layer pore structure, comprising the following steps:

[0056] a: Preparation of the slurry of the catalytic layer of the small hole layer: mix the noble metal catalyst, perfluorosulfonic acid resin solution, low boiling point solvent and deionized water evenly to obtain the catalyst slurry; the diameter of the carbon carrier of the noble metal catalyst is 30-100nm, perfluorinated The mass ratio of the quality of the sulfonic acid resin solid to the total carbon component in the precious metal catalyst is 0.7, the carrier diameter of the precious metal catalyst is between 2-10nm, the loading capacity of the precious metal Pt nanoparticles is 50%, the low boiling point solvent and The mass ratio of deionized water is 10; the solid content in the catalyst slurry is 1%;

[0057] b: Preparation of macroporous catalyst layer slurry: Mix noble metal catalyst, perfluorosulfonic acid resin solution, low boiling...

Embodiment 2

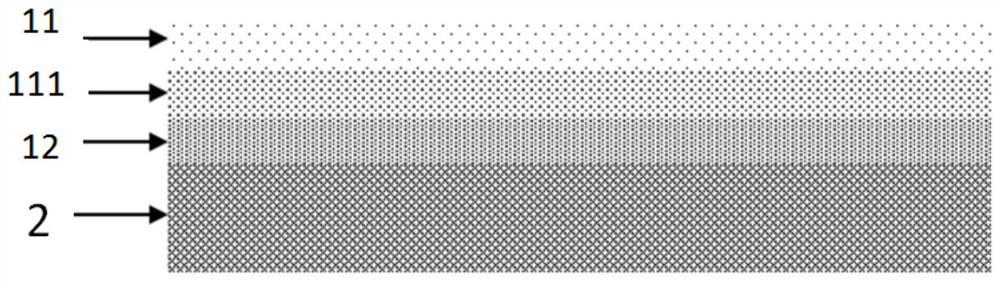

[0061] The preparation method of the catalytic layer having a three-layer pore structure of a macroporous layer, a single-layer transition layer and a small pore layer comprises the following steps:

[0062] a: Preparation of small hole layer catalyst layer slurry, mix noble metal catalyst, perfluorosulfonic acid resin solution, low boiling point solvent and deionized water evenly to obtain catalyst slurry; wherein the diameter of noble metal catalyst carbon carrier is 30-100nm, perfluorinated The mass ratio of the quality of the sulfonic acid resin solid to the total carbon component in the noble metal catalyst is 0.7, the carrier diameter of the noble metal catalyst is between 2-10nm, and the loading capacity of the noble metal Pt nanoparticles is 50%; the low boiling point solvent and The mass ratio of deionized water is 10; the solid content in the catalyst slurry is 1%;

[0063] b: preparation of transition layer catalyst layer slurry, mix noble metal catalyst, perfluoros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com