Correction structure and method for eliminating sunspot phenomenon of image sensor

An image sensor and sunspot technology, applied in the field of correction structure of sunspot phenomenon, can solve the problems of large circuit occupation area, increased power consumption, insufficient driving ability, etc., to reduce the occupation area, improve the driving ability and driving ability Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

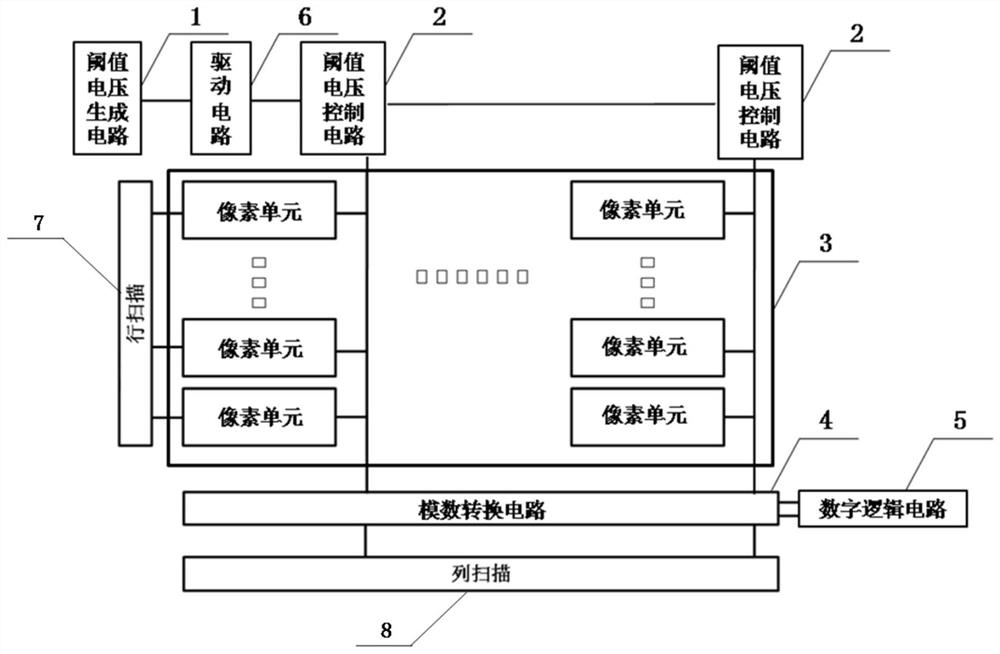

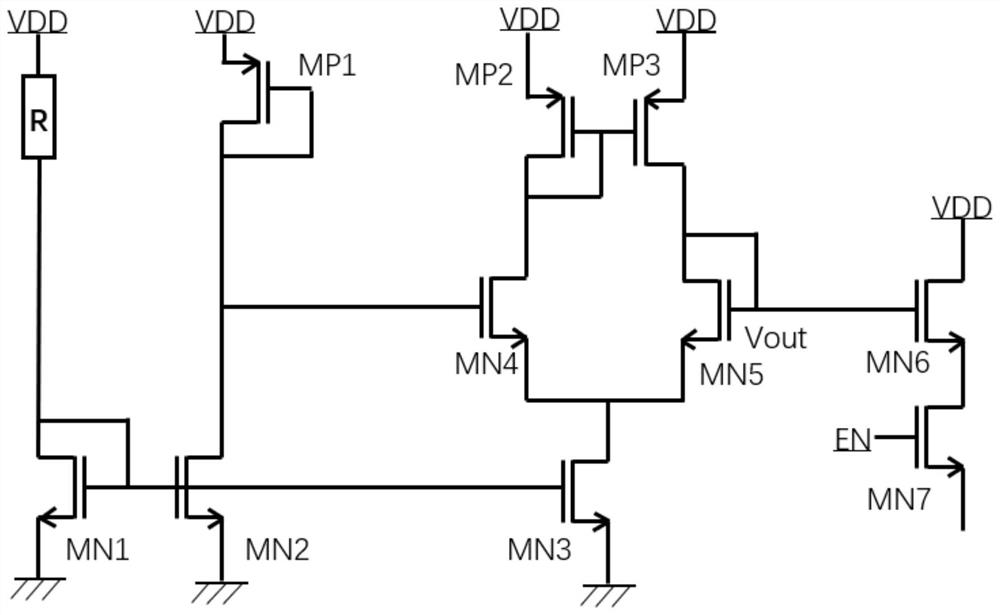

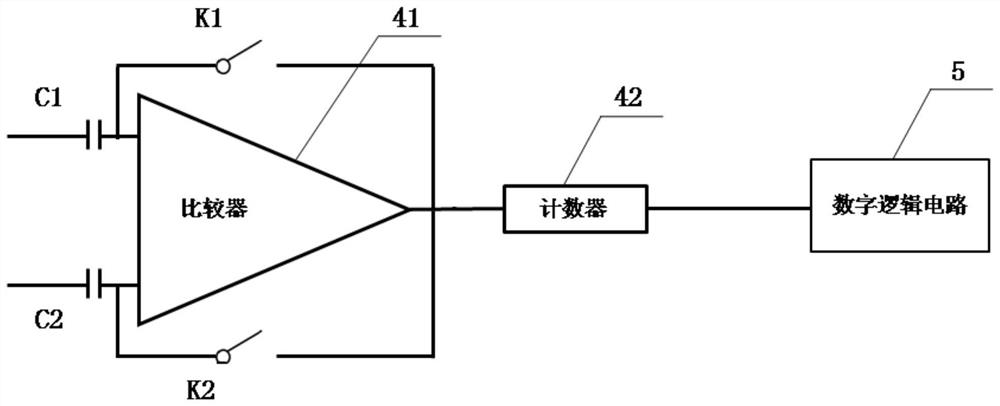

[0048] figure 1 A schematic circuit diagram of a correction structure for eliminating the sunspot phenomenon of an image sensor provided in this embodiment. As shown in the figure, this correction structure includes: a threshold voltage generation circuit 1, a plurality of threshold voltage control circuits 2, a pixel module 3, an analog-to-digital conversion circuit 4, a digital logic circuit 5, a row scan control module 7 and a column scan control module 8 , for driving and selecting the pixel unit output of each row and each column; a plurality of threshold voltage control circuits 2 are connected in parallel on a bus, and the threshold voltage generation circuit 1 is connected to the input end of the bus, and each row A plurality of pixel units are connected on the row scanning control module 7, and a plurality of pixel units of each column are connected on the column scanning control module 8; the pixel module 3 includes multi-row and multi-column pixel units, and the thr...

Embodiment 2

[0061] In combination with the correction structure of Embodiment 1, this embodiment provides a method for eliminating the sunspot phenomenon by using the above correction structure, including:

[0062] Step 1: using the threshold voltage generation circuit to generate a threshold voltage;

[0063] Step 2: using the threshold voltage control circuit to transmit the circuit-generated threshold voltage generated by the threshold voltage to the pixel unit module;

[0064] Step 3: Compensating and correcting the low voltage of the pixel unit through the threshold voltage to obtain a corrected reset voltage of the pixel unit, and ensuring that the reset voltage of the pixel unit is not lower than the threshold voltage;

[0065] Step 4: The pixel module transmits the collected pixel unit reset voltage to the analog-to-digital conversion module, which is obtained after compensating and correcting the pixel unit reset voltage;

[0066] Step 5: using the analog-to-digital conversion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com