Recovery device for high-boiling residues in chlorosilane raffinate

A chlorosilane raffinate and recovery device technology, applied in halosilane, halide silicon compound, fractionation, etc., can solve the problems of high energy consumption, high operation cost, large equipment investment, etc., achieve small volume, low operation cost, The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

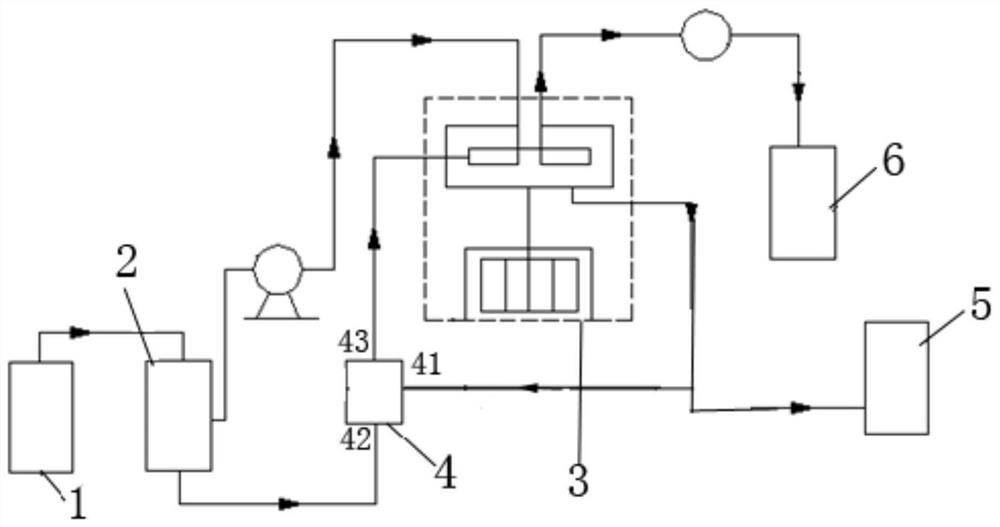

[0038] In an exemplary embodiment, a recovery device for high boilers in chlorosilane raffinate is provided, such as figure 1 , 2 As shown, the recovery unit includes:

[0039] An evaporator 1, which is used for evaporating the chlorosilane raffinate containing high boilers;

[0040] A raw material tank 2, the raw material tank 2 is connected to the evaporation kettle 1 to receive the evaporated chlorosilane raffinate;

[0041] A high gravity rotating packed bed 3, the high gravity rotating packed bed 3 includes a steam inlet 38, a raw material liquid inlet 35, a steam outlet 37 and a liquid outlet 36, and the raw material liquid inlet 35 is connected to the raw material tank 2;

[0042] Reboiler 4, described reboiler 4 comprises first reboiler inlet 41, second reboiler inlet 42 and reboiler outlet 43, and described first reboiler inlet 41 is connected with described liquid outlet 36 , the second reboiler inlet 42 is connected to the raw material tank 2, and the reboiler ou...

Embodiment 2

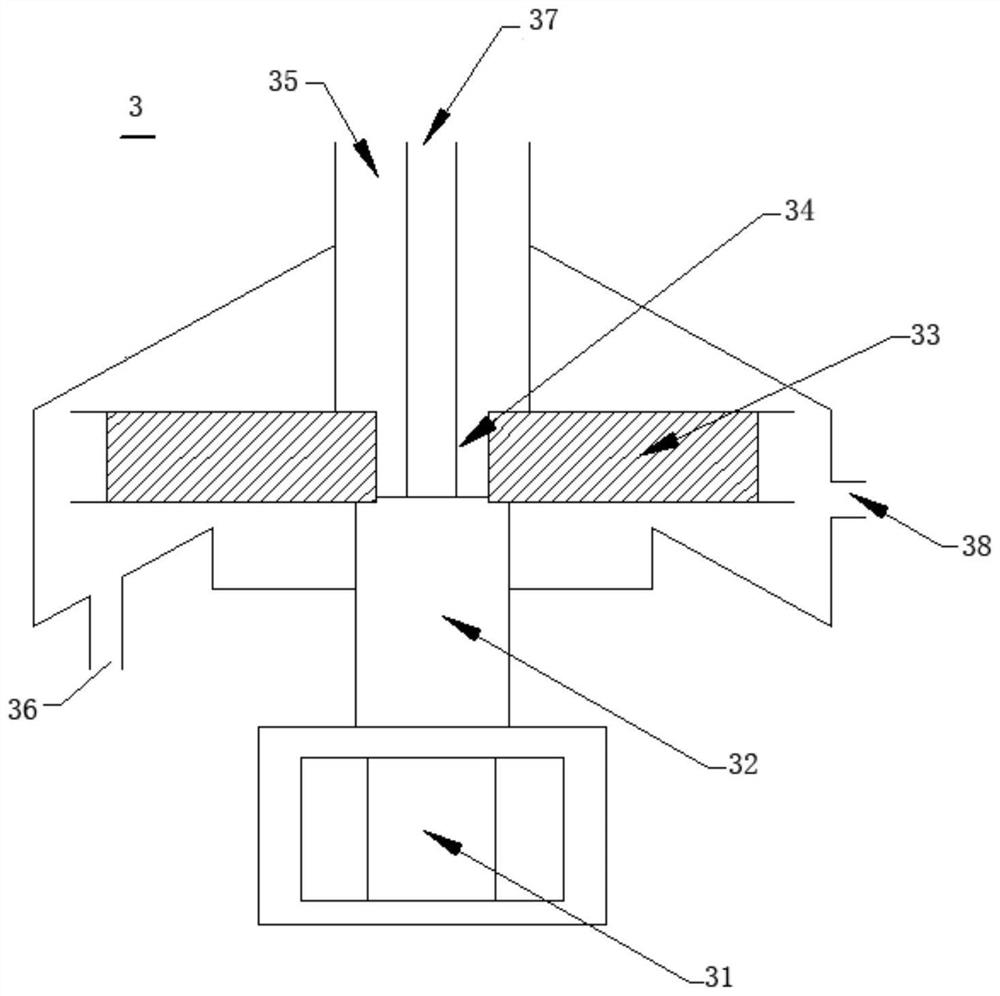

[0052] Based on embodiment 1, a recovery device for high boilers in the chlorosilane raffinate is provided, such as figure 2 As shown, the high-gravity rotating packed bed 3 also includes a high-gravity motor 31, a rotating shaft 32, a packing layer 33 and a liquid distributor 34 arranged on the rotating shaft 32, and the high-gravity motor 31 and the rotating shaft 32 connected, the liquid distributor 34 is used to evenly distribute the liquid in the packing layer 33 .

[0053] Further, the packing layer 33 includes an inner layer and an outer layer that communicate with each other, the inner layer is connected to the raw material liquid inlet 35 , and the outer layer is connected to the steam inlet 38 . The raw material liquid is added into the rotating bed and flows from the inside of the packing layer to the outside of the packing layer, and the steam conducts mass transfer and heat transfer in a countercurrent direction from the outside of the packing layer to the inside...

Embodiment 3

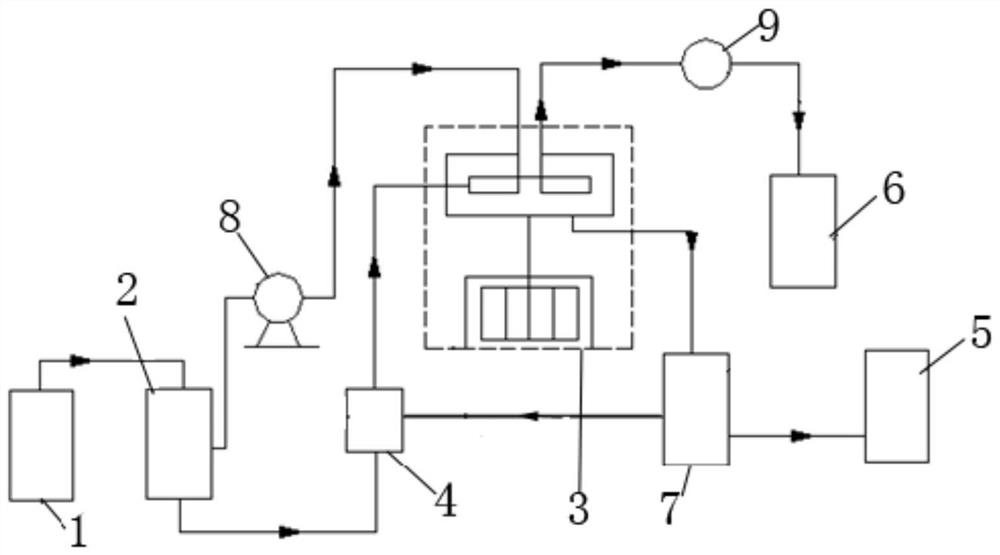

[0059] Based on embodiment 1, a recovery device for high boilers in the chlorosilane raffinate is provided, such as image 3 As shown, the liquid outlet 36 is provided with a liquid collection tank 7, and the liquid collection tank 7 is connected to the first reboiler inlet 41 and the first recovery tank 5 respectively.

[0060] Further, the pipeline connecting the raw material tank 2 and the raw material liquid inlet 35 is provided with a pump 8. Specifically, the pump 8 uses power to smoothly transport the liquid in the raw material tank 2 to the high-gravity rotating packed bed 3 .

[0061] Further, a heat exchanger 9 is provided on the pipeline connecting the second recovery tank 6 and the steam outlet 37 . Specifically, the heat exchanger 9 selects a condenser to cool the steam and collect it in the second recovery tank 6 .

[0062] Further, the working temperature of the evaporator 1 is 150°C-200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com