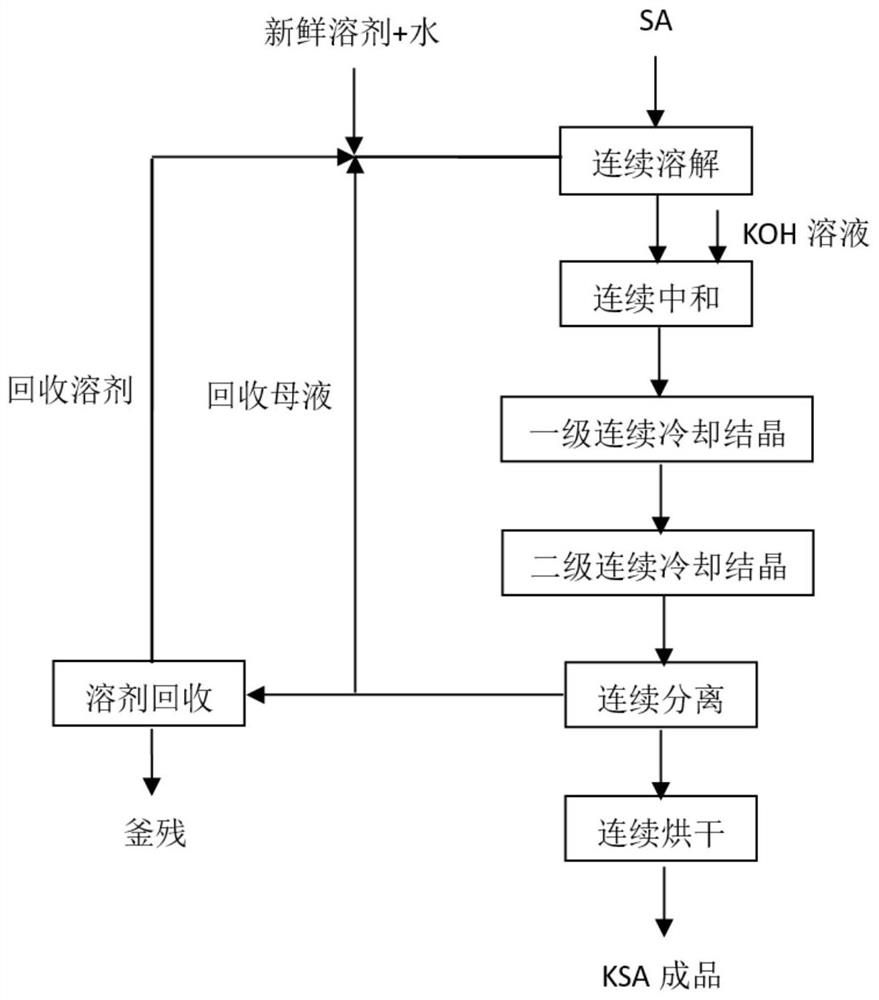

Method for producing potassium sorbate through liquid-liquid neutralization reaction and continuous cooling crystallization

A technology of potassium sorbate and cooling crystallization, which is applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc. It can solve uneven neutralization reactions, low product quality, and many by-products, etc. problems, to achieve the effect of reducing drying energy consumption, high product quality, and controllable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

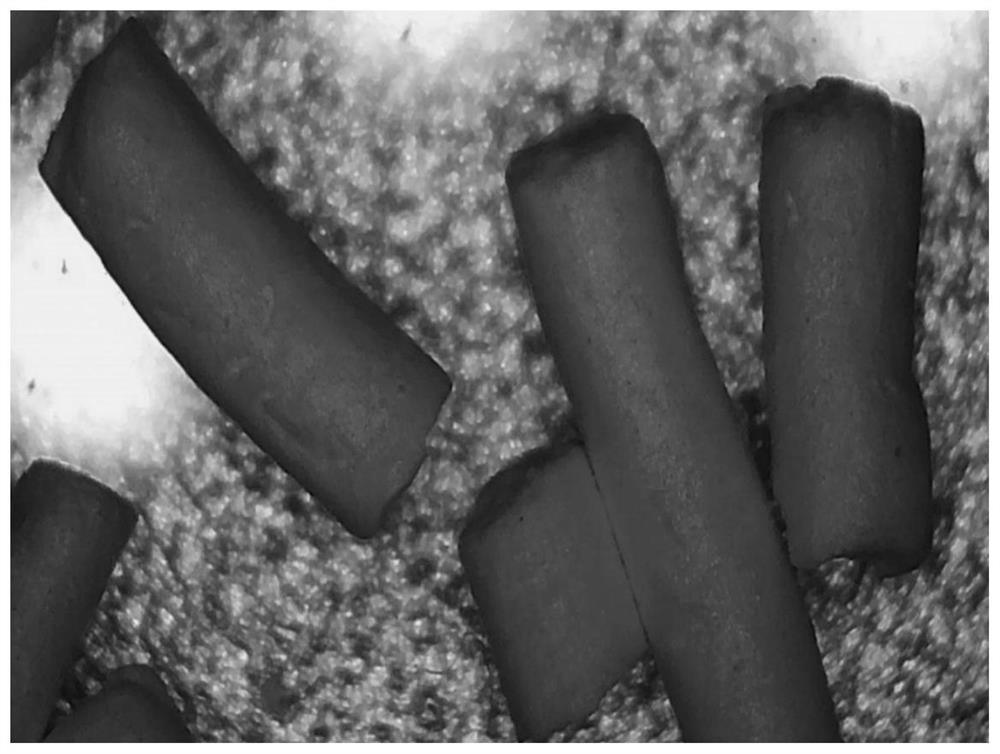

Examples

Embodiment 1

[0038] (1) Take by weighing 100g sorbic acid and 550g 60% alcohol content aqueous solution and mix and dissolve continuously at 50°C. After dissolving, the mass concentration of sorbic acid is 15.4%; The acid solution and 500g of potassium hydroxide aqueous solution with a concentration of 10.1wt% were injected into the neutralization reactor for continuous neutralization reaction, the temperature of the neutralization reaction was 70°C, the reaction residence time was 3h, and the pH was maintained at 10.5 during the period;

[0039] (2) Press the flow rate of 9.9mL / min to squeeze the obtained potassium sorbate neutralization liquid into a two-stage continuous kettle formula crystallizer for continuous cooling and crystallization, and the pressure of the crystallization system is normal pressure, wherein, the crystallization temperature Control at 45°C, the crystallization residence time is 3h, the crystallization temperature of the secondary crystallizer is controlled at 13°C, a...

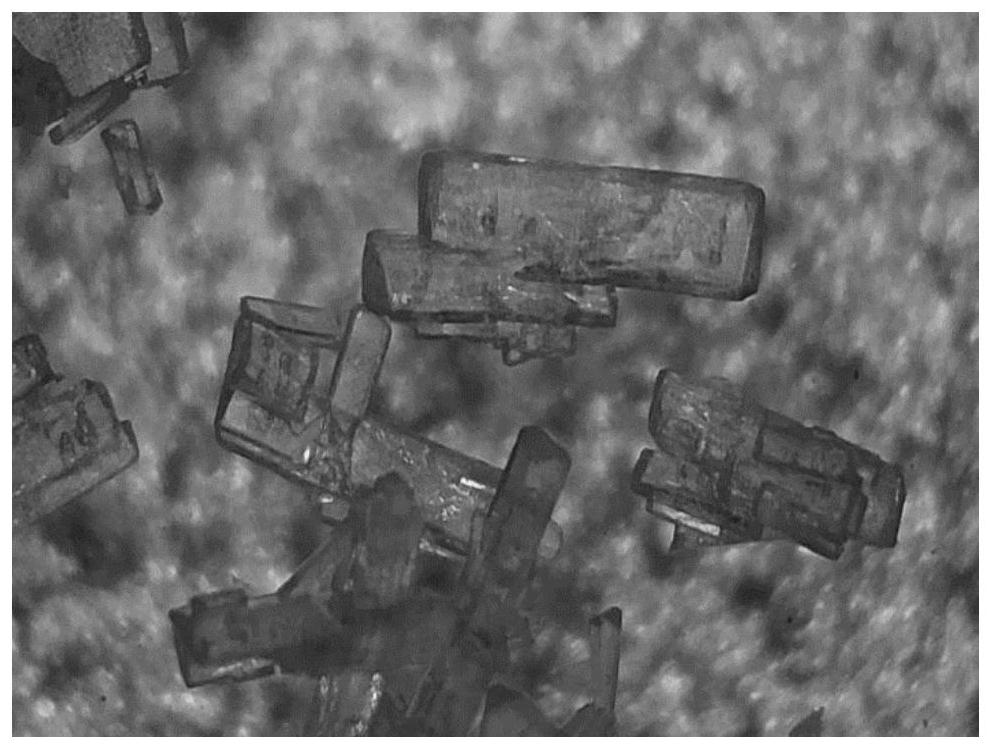

Embodiment 2

[0042] (1) The aqueous solution of 100g sorbic acid and 170g 60% acetone concentration is continuously mixed and dissolved at 70°C, and the mass concentration of sorbic acid after dissolving is 37%; The acid solution and 270g of 18.7wt% potassium hydroxide aqueous solution are continuously poured into the neutralization reactor for continuous neutralization reaction, the temperature of the neutralization reaction is 80°C, the reaction residence time is 1h, and the pH is maintained at 10.5 during the period;

[0043] (2) Press the flow rate of 11mL / min again and the potassium sorbate neutralization liquid that step (1) obtains is squeezed into two-stage continuous kettle type crystallizer and carries out continuous cooling and crystallization, and the pressure of crystallization system is normal pressure, and the primary crystallizer crystallization The temperature is controlled at 50°C, the crystallization residence time is 1.5h, the crystallization temperature of the secondary...

Embodiment 3

[0046] (1) 100g sorbic acid and 270g 45% acetone concentration aqueous solution are continuously mixed and dissolved at 70°C, and the mass concentration of sorbic acid after dissolving is 27%; % of sorbic acid solution and 200g 25.3wt% potassium hydroxide aqueous solution into the neutralization reactor for continuous neutralization reaction, the temperature of the neutralization reaction is controlled at 80 ° C, the residence time is 2h, and the pH of the neutralization reaction is maintained at 10 during the period;

[0047] (2) Press the flow rate of 10.8mL / min again the potassium sorbate neutralization liquid that above-mentioned step (1) obtains is squeezed into two-stage continuous tubular crystallizer and carry out continuous cooling and crystallization, and crystallization system pressure is normal pressure, and wherein, one-stage The crystallization temperature of the crystallizer is controlled at 47°C, and the crystallization residence time is 3h. The crystallization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com