Preparation of Co-MOF-74 material with three-dimensional structure and VOCs application of Co-MOF-74 material

A co-mof-74, three-dimensional technology, used in catalyst activation/preparation, gas treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as air quality and adverse effects on human health, and achieve The product shape and size are controllable, the yield is high, and the phase is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

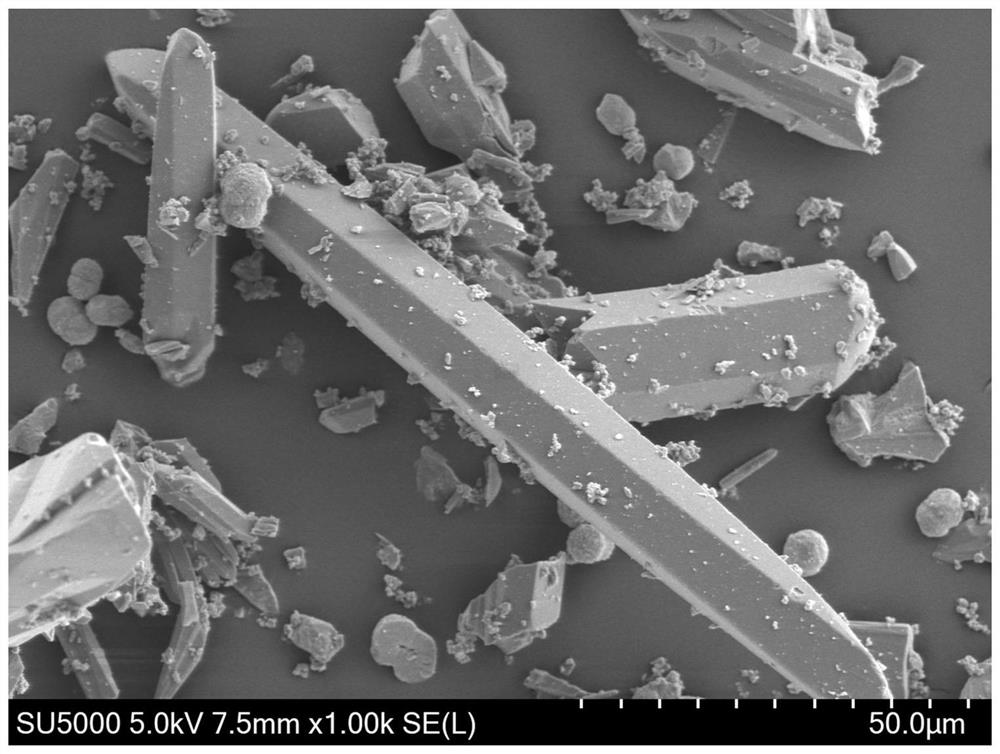

[0029] Weigh 0.198g of 2,5-dihydroxyterephthalylene and 1.164g of Co(NO 3 ) 2 ·6H 2 O was added to 100mL (DMF:EtOH:H 2 O=1:1:1), sonicated for 5 minutes to mix the solution evenly, placed in a 100 mL reactor, aged at 100°C for 24 hours, then centrifuged and filtered to obtain a solid, which was washed three times with ethanol and water, and then heated at 100°C Co-MOF-74 crystals with rod-like three-dimensional structure were obtained after drying.

[0030] The catalytic activity of the Co-MOF-74 sample with rod-shaped three-dimensional structure prepared in this embodiment was tested. Specifically: take 0.1 g of the sample prepared in this embodiment and place it in a quartz tube with an inner diameter of 6 mm and a length of 75 cm. Quartz wool is placed in the quartz tube as a carrier to prevent the catalyst from falling. Set the reaction temperature to the temperature program mode, and the space velocity is 120000mL g -1 h -1 , the mixed gas of oxygen and nitrogen and...

Embodiment 2

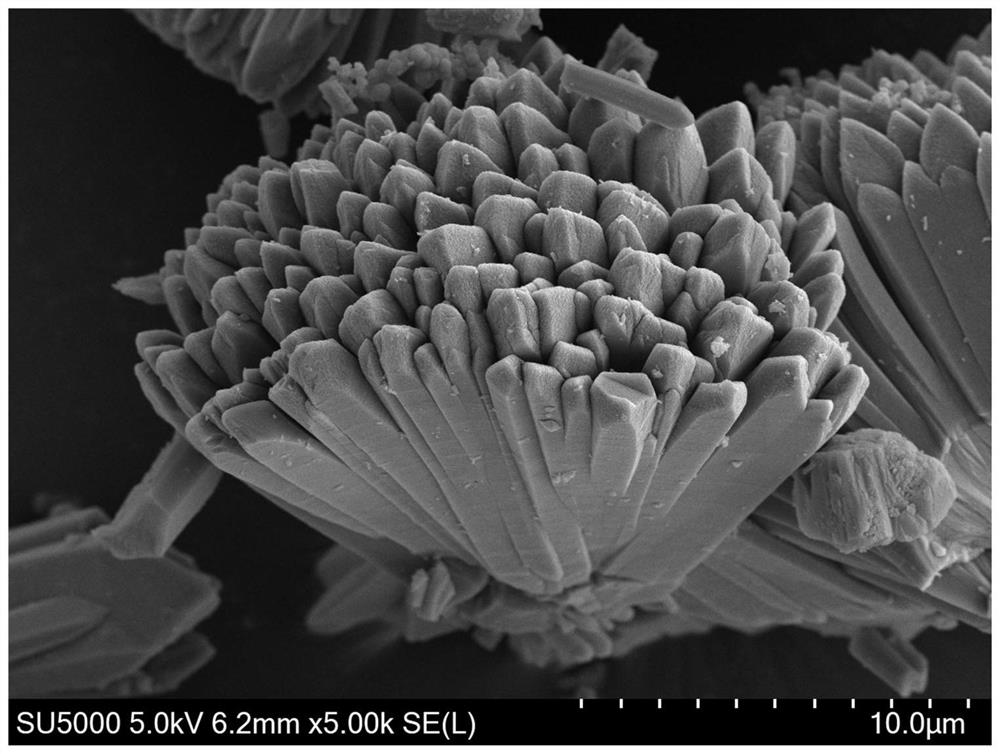

[0032] 0.246g 2-MI dissolved in 10ml DMF:EtOH:H 2 O=1:1:1 mixed evenly; 0.198g 2,5-dihydroxyterephthalic acid and 1.164g Co(NO 3 ) 2 ·6H 2 O was added to 100mL DMF:EtOH:H2 O=1:1:1, ultrasonication for 5 minutes is used to mix the solution evenly, and the 2-MI mixed solution is evenly added dropwise to the above mixed solution, stirred in a magnetic stirrer for 10 minutes, and then placed in a 100mL reactor for aging at 100°C for 24 hours, then After centrifugal filtration, the obtained solid was washed three times with ethanol and then with ultrapure water, and dried to obtain a flower-like three-dimensional Co-MOF-74 crystal.

[0033] The catalytic activity of the Co-MOF-74 sample with a flower-like three-dimensional structure prepared in this embodiment was tested. Specifically: take 0.1 g of the sample prepared in this embodiment and place it in a quartz tube with an inner diameter of 6 mm and a length of 75 cm. Quartz wool is placed in the quartz tube as a carrier to pr...

Embodiment 3

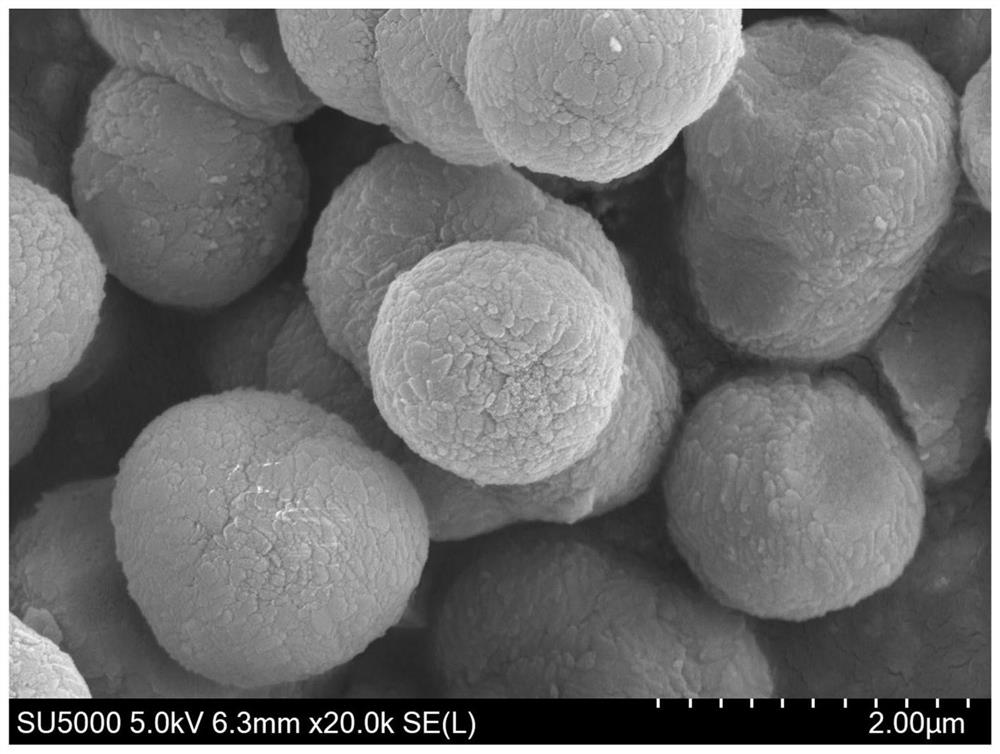

[0035] 0.492g 2-MI dissolved in 10ml DMF:EtOH:H 2 O=1:1:1 mixed evenly; 0.198g 2,5-dihydroxyterephthalic acid and 1.164g Co(NO 3 ) 2 ·6H 2 O was added to 100 mL DMF:EtOH:H 2 O=1:1:1, mix evenly, add the 2-MI mixed solution evenly to the above mixed solution dropwise, stir for 10mim, then put it in a 100mL reactor for aging at 100°C for 24h, and then centrifuge to obtain a solid that is first washed with ethanol and then Washed three times with ultrapure water, and dried to obtain spherical Co-MOF-74 crystals with three-dimensional structure.

[0036] The catalytic activity of the Co-MOF-74 sample with a spherical three-dimensional structure obtained in this embodiment was tested in a catalytic micro-reaction device. Specifically: take 0.1 g of the sample prepared in this embodiment and place it in a quartz tube with an inner diameter of 6 mm and a length of 75 cm, and place quartz wool in the quartz tube as a carrier to prevent the catalyst from falling. Set the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com