Manufacturing method of copper zinc tin sulfur selenium semiconductor film and application

A copper-zinc-tin-sulfur-selenium and semiconductor technology, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of limited popularization and application, complicated procedures, etc., and achieves simple equipment and preparation process, high purity, Phase homogeneous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

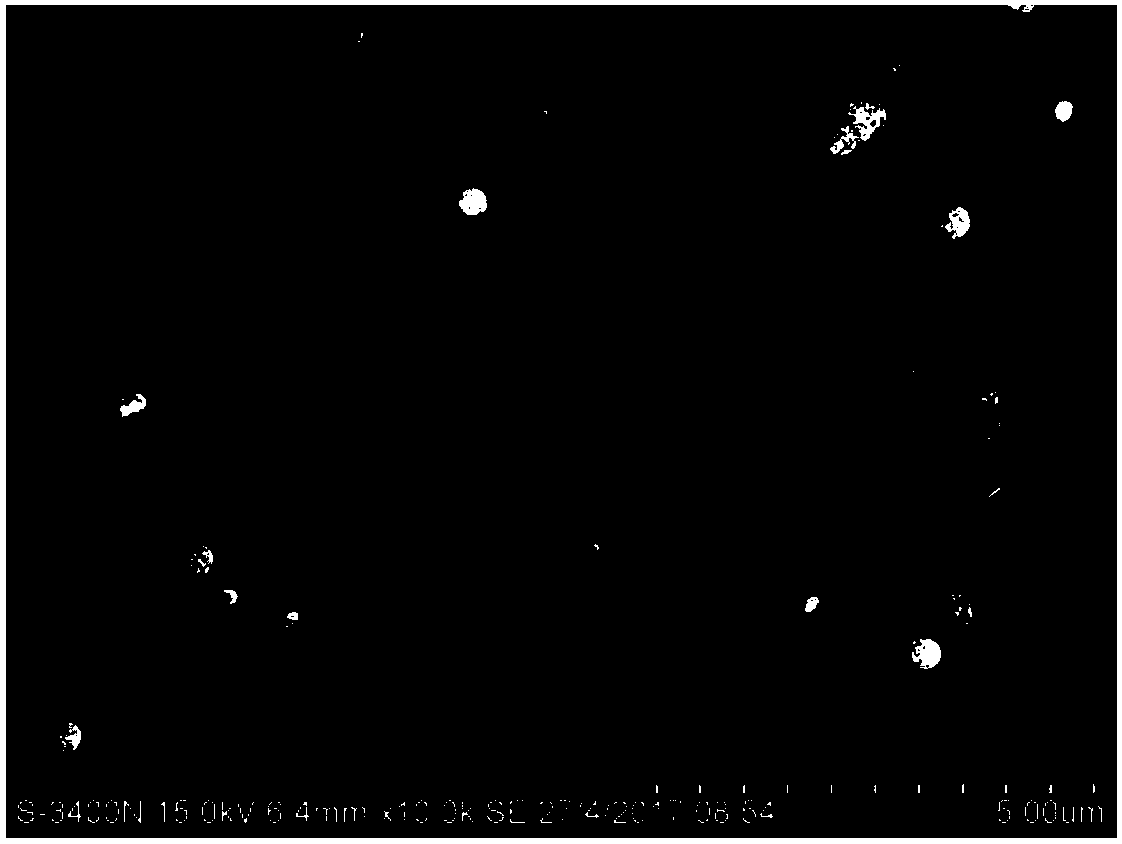

Embodiment 1

[0031] Add 1.5mmol cupric chloride, 3mmol zinc chloride, 0.75mmol stannous chloride and 0.375mmol CTAB to 60ml ethanol solution in turn, stir until completely dissolved; then add 7.5mmol thiourea, stir until completely dissolved; finally add 7.5mmol of selenourea was magnetically stirred until completely dissolved to obtain a reaction precursor. Put the cleaned FTO glass into the polytetrafluoroethylene lining of the autoclave, and place it at an angle of 30° with the wall of the autoclave with the conductive side facing down. Transfer the prepared reaction precursor solution to the inner liner, and seal the kettle. Put the high-pressure reactor into a high-temperature blast drying oven, and react at 200°C for 24h. After the reaction was over, it was cooled naturally. The FTO glass deposited with the CZTSSe thin film was taken out, washed three times with absolute ethanol and deionized water respectively, and then vacuum-dried at 60° C. for 4 hours to obtain a CZTSSe semicon...

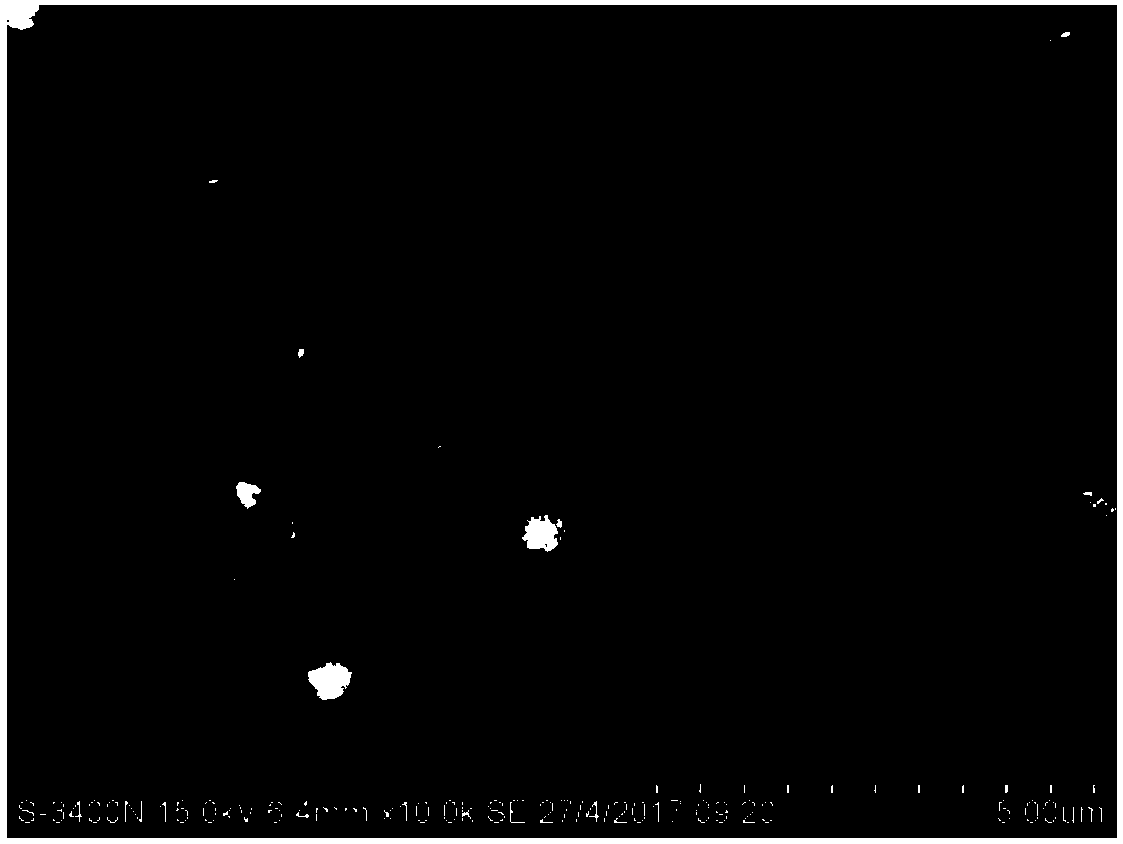

Embodiment 2

[0034] Add 1.5mmol cupric chloride, 3mmol zinc chloride, 0.75mmol stannous chloride and 0.375mmol CTAB in 60ml of ethanol solution successively, stir until completely dissolved by magnetic force; then add 12mmol thiourea, stir until completely dissolved by magnetic force; finally add 3mmol of selenium Urea was magnetically stirred until completely dissolved to obtain a reaction precursor. Put the cleaned FTO glass into the polytetrafluoroethylene lining of the autoclave, and place it at an angle of 35° with the wall of the vessel with the conductive side facing down. Transfer the prepared reaction precursor solution to the inner liner, and seal the kettle. Put the high-pressure reactor into a high-temperature blast drying oven, and react at 210°C for 22h. After the reaction was over, it was cooled naturally. The FTO glass deposited with the CZTSSe thin film was taken out, washed three times with absolute ethanol and deionized water respectively, and then vacuum-dried at 60° ...

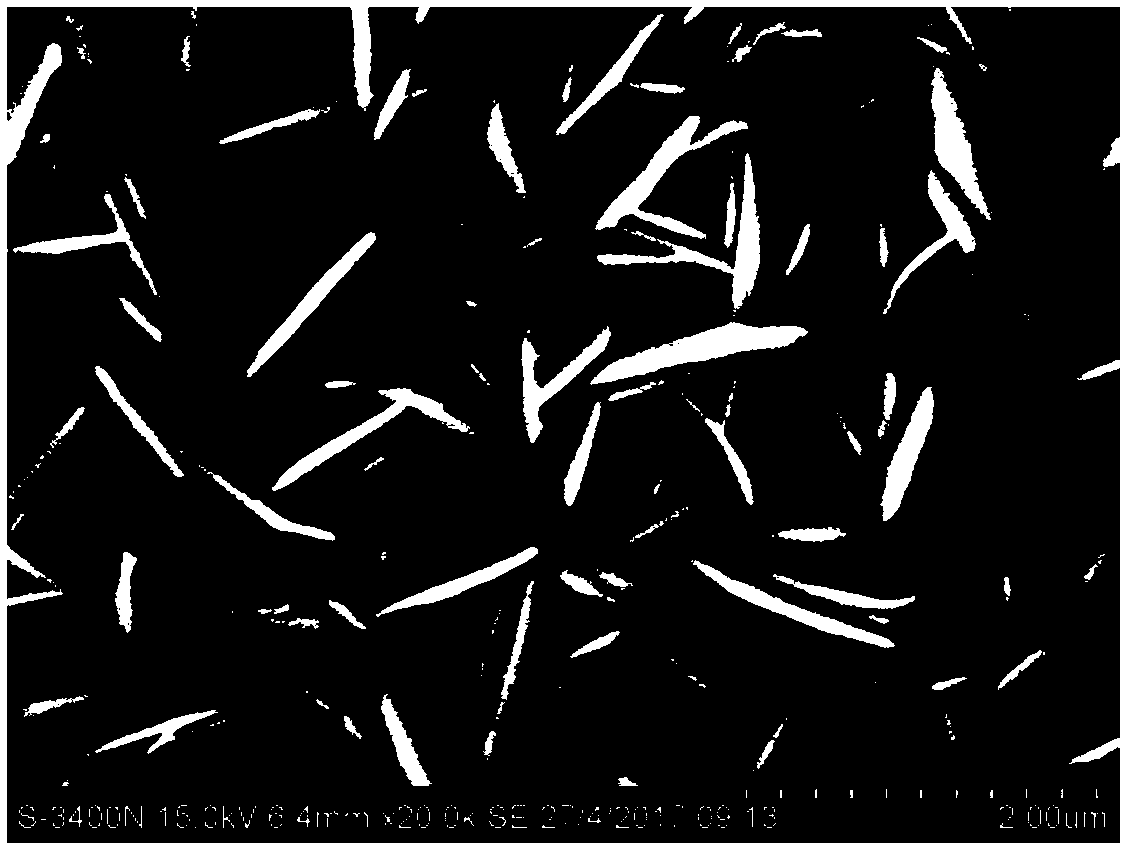

Embodiment 3

[0036] Add 1.5mmol copper chloride, 3mmol zinc chloride, 0.75mmol stannous chloride and 0.375mmol CTAB to 60ml ethanol solution in turn, stir until completely dissolved; then add 3mmol thiourea, stir until completely dissolved; finally add 12mmol Selenourea was magnetically stirred until completely dissolved to obtain a reaction precursor. Put the cleaned FTO glass into the polytetrafluoroethylene lining of the autoclave, and place it at an angle of about 40° with the wall of the autoclave with the conductive side facing down. Transfer the prepared reaction precursor solution to the inner liner, and seal the kettle. Put the high-pressure reactor into a high-temperature blast drying oven, and react at 200°C for 24h. After the reaction was over, it was cooled naturally. The FTO glass deposited with the CZTSSe thin film was taken out, washed three times with absolute ethanol and deionized water respectively, and then vacuum-dried at 60° C. for 4 hours to obtain a CZTSSe semicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com