Preparation method of steel surface DLC (diamond-like carbon) coating based on ionic nitriding and multi-layer compounding

An ion nitriding, multi-layer composite technology, applied in the coating, superimposed layer plating, ion implantation plating and other directions, can solve the friction coefficient of diamond-like coating is sensitive, the internal stress of diamond-like coating is large, and the metal matrix Problems such as poor bonding force, to achieve the effect of increasing hardness gradient, improving thermal stability, and improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

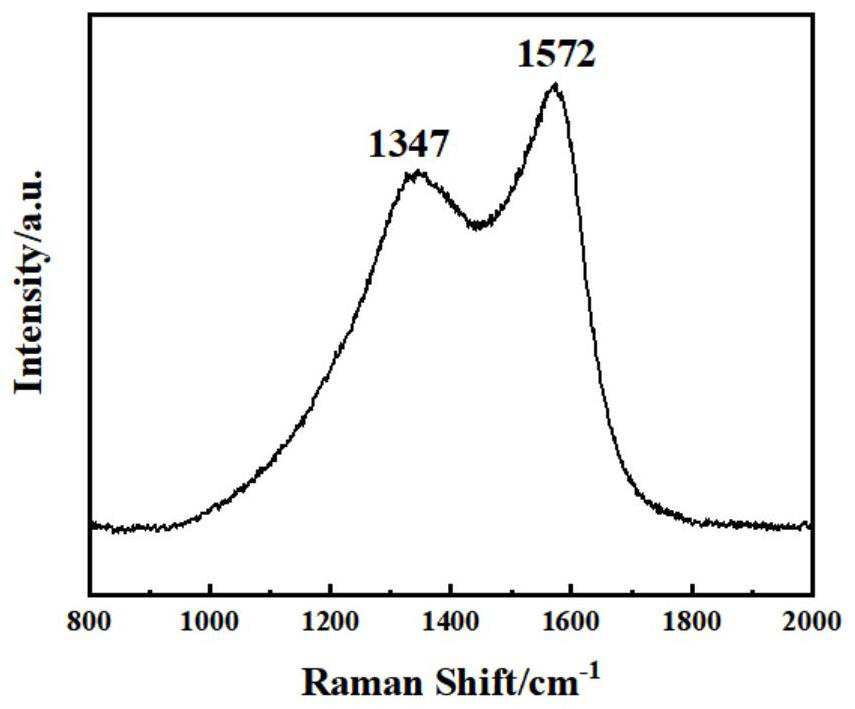

Image

Examples

Embodiment 1

[0039] ① Ion nitriding on the surface of the base steel

[0040] First, put the 25Cr3Mo3NiNbZr steel sample into the high-energy ion source-assisted PECVD equipment, and vacuumize to 5×10 -3 Below Pa, and heated to 400°C; then etched the surface of the workpiece with Ar ions for 40 minutes; then passed through 300sccm Ar, 400sccm N 2 、1000sccmH 2 The mixed gas, the ion source filament current was adjusted to 250A, the ion column current was set to 120A, the bias power supply was in unipolar pulse mode, the output voltage was 100V, and the ion nitriding was carried out for 100min to obtain a 20μm thick ion nitriding layer.

[0041] ② Deposition of Cr transition layer

[0042]The furnace temperature was lowered to 200°C, and the surface of the workpiece was etched with Ar ions for 20 min. Then, Ar gas was introduced until the pressure was 0.4 Pa, and the power of Cr and WC cathodes was set to 10 kW, and the surface of the target was cleaned for 10 min. Continuously feed argo...

Embodiment 2

[0050] ① Ion nitriding on the surface of the base steel

[0051] First, put the AF1410 steel sample into the high-energy ion source assisted PECVD equipment, and vacuumize to 5×10 -3 Below Pa, and heated to 450°C; then etched the surface of the workpiece with Ar ions for 30 minutes; then passed through 300sccm Ar, 400sccm N 2 、1000sccmH 2 The ion source filament current is adjusted to 200A, the ion column current is set to 100A, the bias power supply adopts unipolar pulse mode, the pulse frequency is 60kHz, the duty cycle is 0.75, the output voltage is 100V, and the ion nitriding takes 150min to obtain 30μm Thick ionic nitride layer.

[0052] ② Deposition of Cr transition layer

[0053] First, the furnace temperature was lowered to 150°C, and the surface of the workpiece was etched with Ar ions for 30 min. Then, Ar gas was introduced until the pressure was 0.3 Pa, and the power of Cr and WC cathodes was set to 10 kW, and the surface of the target was cleaned for 10 min. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com