High-quality semiconductor epitaxial wafer and preparation method thereof

A semiconductor, high-quality technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effects of improving leakage performance and luminous efficiency, improving uniformity of luminous wavelength, and precise and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

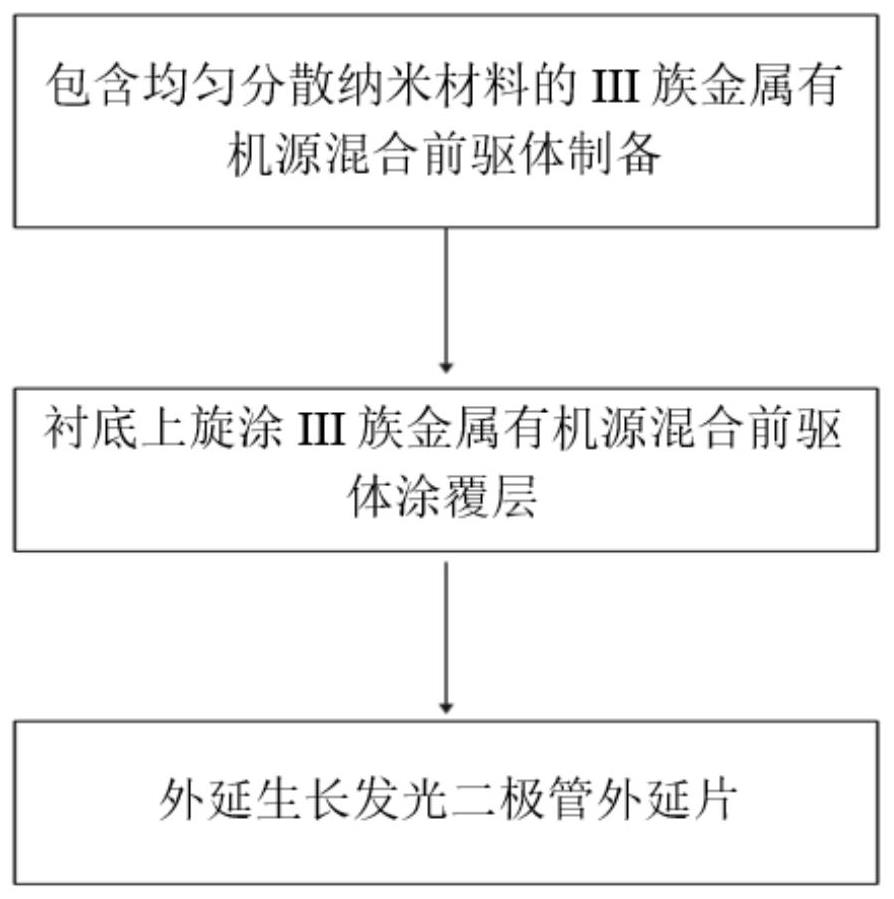

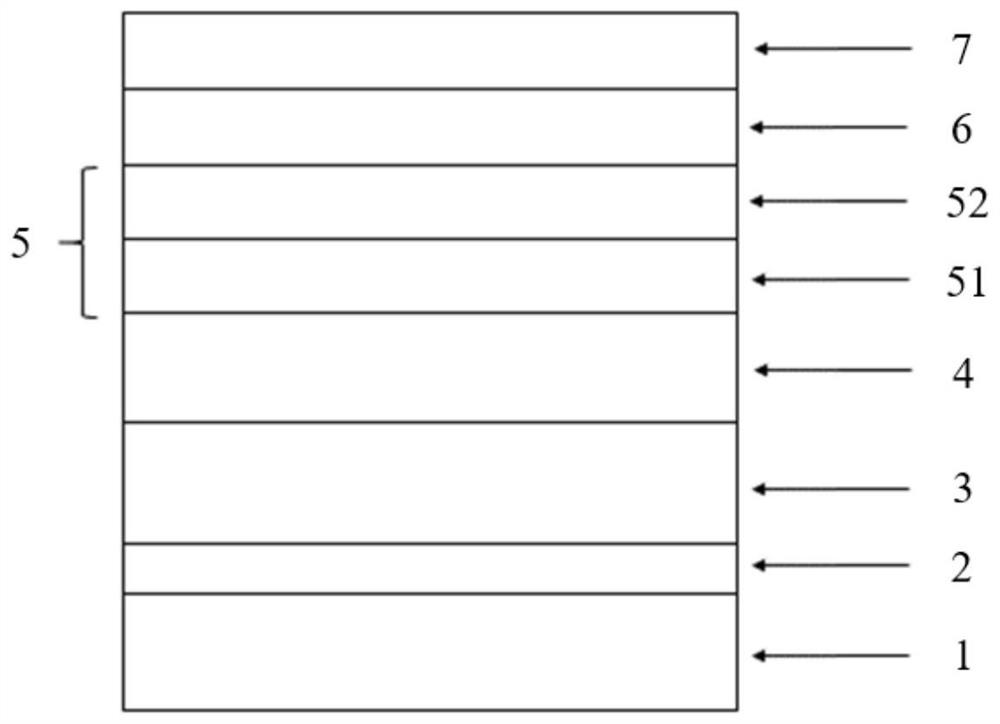

[0028] Another aspect of the embodiments of the present invention provides a method for preparing a high-quality semiconductor epitaxial wafer comprising:

[0029] Provide Group III metal-organic source hybrid precursors containing uniformly dispersed nanomaterials;

[0030] Coating the Group III metal-organic source mixed precursor on the substrate to obtain the Group III metal-organic source mixed precursor coating layer, and then placing the substrate with the Group III metal-organic source mixed precursor coating layer on In the MOCVD reaction chamber, the metal-organic source of group III is introduced, and annealing and recrystallization are carried out in the mixed atmosphere of group V element source and reducing gas, so as to form uniformly distributed nanomaterials and nano-growth structures of group III-V compounds, and obtain Stress relief buffer layer;

[0031] A semiconductor epitaxial structure is grown on the stress release buffer layer to produce a high-quali...

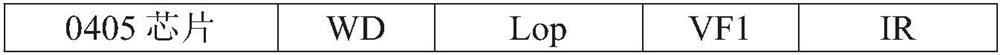

Embodiment 1

[0094] 1) Preparation of Ni nanoparticle dispersion

[0095] Using absolute ethanol, add 30% by mass fraction of nano-Ni powder with a diameter of 30 to 80 nm, add 0.15% by mass fraction of citric acid dispersant, and sonicate for 2 hours at room temperature;

[0096] 2) Preparation of Ni nanoparticles TMG source

[0097] The Ni nanoparticles were separated from the solvent, quickly dried and immediately mixed with a high-purity TMG source. The mass fraction of Ni nanoparticles was 40%, and ultrasonicated at 40°C for 60 minutes to obtain a TMG source mixed precursor with uniformly dispersed Ni nanoparticles;

[0098] 3) Spin coating Ni nanoparticles TMG source mixed precursor

[0099] In the glove box N 2 In the atmosphere, the Ni nanoparticle TMG source mixed precursor is spin-coated on the sapphire substrate at a speed of 4000rpm by the spin coating method of the homogenizer, and the TMG source mixed precursor with a thickness of 30nm uniformly dispersed Ni nanoparticles i...

Embodiment 2

[0108] 1) Preparation of Ni nanoparticle dispersion

[0109] Using absolute ethanol, add 30% by mass fraction of nano-Ni powder with a diameter of 30 to 80 nm, add 0.15% by mass fraction of citric acid dispersant, and sonicate for 2 hours at room temperature;

[0110] 2) Preparation of Ni nanoparticles TMG source

[0111] The Ni nanoparticles were separated from the solvent, quickly dried and immediately mixed with a high-purity TMG source. The mass fraction of Ni nanoparticles was 40%, and ultrasonicated at 40°C for 60 minutes to obtain a TMG source mixed precursor with uniformly dispersed Ni nanoparticles;

[0112] 3) Spin coating Ni nanoparticles TMG source mixed precursor

[0113] In the glove box N 2 In the atmosphere, the Ni nanoparticle TMG source mixed precursor is spin-coated on the sapphire substrate at a speed of 4000rpm by the spin coating method of the homogenizer, and the TMG source mixed precursor with a thickness of 800nm uniformly dispersed Ni nanoparticle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com