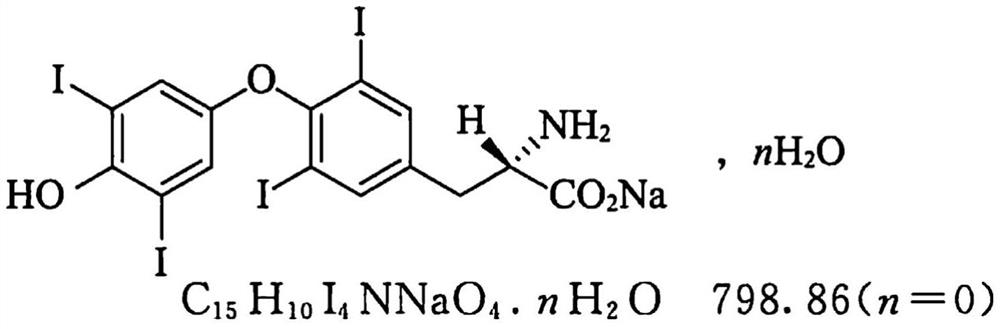

Levothyroxine sodium micro-tablet as well as preparation method and preparation thereof

A technology of levothyroxine sodium and microtablets, which is applied in the directions of pill delivery, pharmaceutical formulations, medical preparations with inactive ingredients, etc., can solve problems such as uneven content of levothyroxine sodium, improve bioavailability, solve Non-uniform, uniformity-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

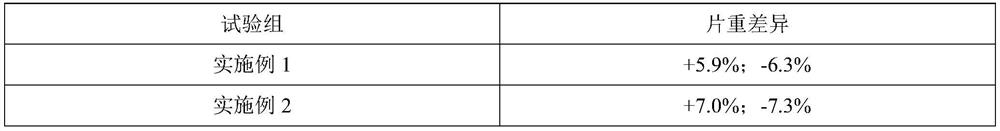

Examples

Embodiment 1

[0060] A levothyroxine sodium microtablet, the components: 0.05 parts of levothyroxine sodium, 59.95 parts of microcrystalline cellulose, 30 parts of mannitol, 3.67 parts of croscarmellose sodium, 1.83 parts of low-substituted hydroxypropyl cellulose, 3 parts of hydroxypropyl cellulose, 1 part of magnesium stearate, 0.5 parts of silicon dioxide;

[0061] The preparation method of above-mentioned microchip:

[0062] (1) Get levothyroxine sodium and hydroxypropyl cellulose dissolved in water and disperse evenly;

[0063] (2) Spray (1) into the mixture of microcrystalline cellulose and mannitol, granulate, and dry;

[0064] (3) mix (2) with croscarmellose sodium, low-substituted hydroxypropyl cellulose, magnesium stearate, and silicon dioxide;

[0065] (4) Made into microtablets with a diameter of 3 mm and a tablet weight of 25 mg, containing 12.5 μg of levothyroxine sodium per tablet.

Embodiment 2

[0067] A levothyroxine sodium microtablet, the components: 0.01 parts of levothyroxine sodium, 43.99 parts of microcrystalline cellulose, 45 parts of mannitol, 4.5 parts of croscarmellose sodium, 4 parts of hypromellose, stearin 0.5 parts of magnesium oxide, 2 parts of silicon dioxide;

[0068] The preparation method of above-mentioned microchip:

[0069] (1) get hydroxypropyl cellulose and make solution with water;

[0070] (2) Get levothyroxine sodium, carry out micronization with jet mill, control particle size result to be D 90 = 23.19 μm;

[0071] (3) Disperse (2) with water, mix with (1), and shear with a high-speed dispersing shear at a speed of 6000 rpm for 5 minutes;

[0072] (4) Get microcrystalline cellulose and mannitol, mix in wet mixing granulator, stirring speed 300rpm, shearing speed

[0073] 1000rpm, time 3min;

[0074] (5) Spray (3) into (4) with an atomization system, and the result of controlling the droplet size is D 90 =100μm, at the same time, stir...

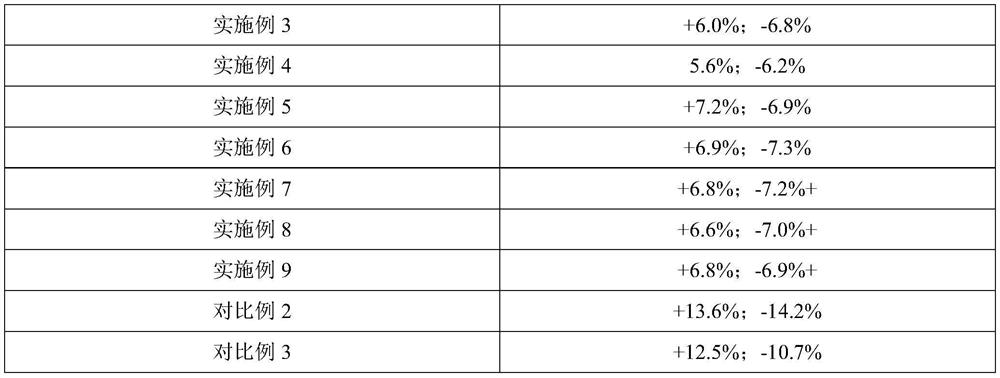

Embodiment 3

[0080] A levothyroxine sodium microtablet, components: 0.0125 parts of levothyroxine sodium, 67.9875 parts of microcrystalline cellulose, 18 parts of mannitol, 6.5 parts of croscarmellose sodium, 5 parts of hypromellose, stearin Magnesium acid 2 parts, silicon dioxide 0.5 parts.

[0081] The preparation method of above-mentioned microchip:

[0082] (1) get hydroxypropyl cellulose and make solution with water;

[0083] (2) Get levothyroxine sodium, carry out micronization with jet mill, control particle size result to be D 90 = 42.56 μm;

[0084] (3) Disperse (2) with water, mix with (1), and shear with a high-speed dispersing shear at a speed of 8000 rpm for 2 minutes;

[0085] (4) Take microcrystalline cellulose and mannitol, mix them in a boiling granulator, control the material temperature not to exceed 35°C, and boil for 5 minutes;

[0086] (5) Spray (3) into (4) with an atomization system, and the result of controlling the droplet size is D 90 =190μm, at the same tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com