Preparation and application of heteroatom-containing carbon microsphere particle electrode

A technology of granular electrodes and carbon microspheres, which is applied in the direction of water pollutants, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex preparation, lack of interaction, and high cost, and achieve simple preparation methods, High degradation rate and current efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

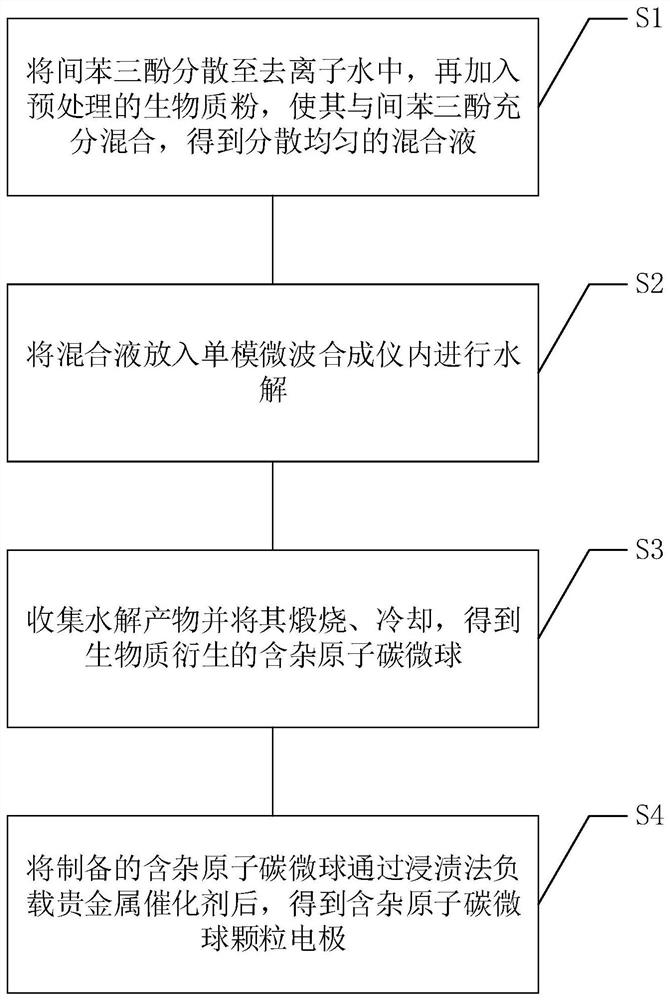

[0029] Further, the preparation method of the pretreated biomass powder comprises: cutting the dried biomass into 1 cm and pulverizing it with 0.05mol / L H 2 SO 4 Shake for 4 hours to remove impurities, wash with deionized water to remove neutrality, dry at 60°C for 8 hours, and pass through a 200-mesh sieve for later use.

[0030] Further, biomass and H 2 SO 4 The mass ratio of the solution is 1:20-1:30.

[0031] Further, the method for preparing the mixed solution includes: putting phloroglucinol into deionized water and ultrasonicating for 5 minutes, then adding biomass powder for ultrasonication for 1 hour, and magnetically stirring for 12 hours, wherein the mass of phloroglucinol, biomass and deionized water The ratio is 1:5:100~1:15:200.

[0032] Further, the hydrolysis conditions of the single-mode microwave synthesizer are as follows: the heating rate is 40°C / min to 200°C, the pressure is 10atm, the magnetic stirring speed is 1500r / min, and the hydrolysis time is 1-...

Embodiment 1

[0039] 1. Preparation of carbon microsphere electrodes

[0040] (1) Grinding the dried corncobs, using 0.05mol / L H 2 SO 4 Shake for 4 hours to remove impurities, wash with deionized water until neutral, dry at 60°C, pass through a 200-mesh sieve, and set aside.

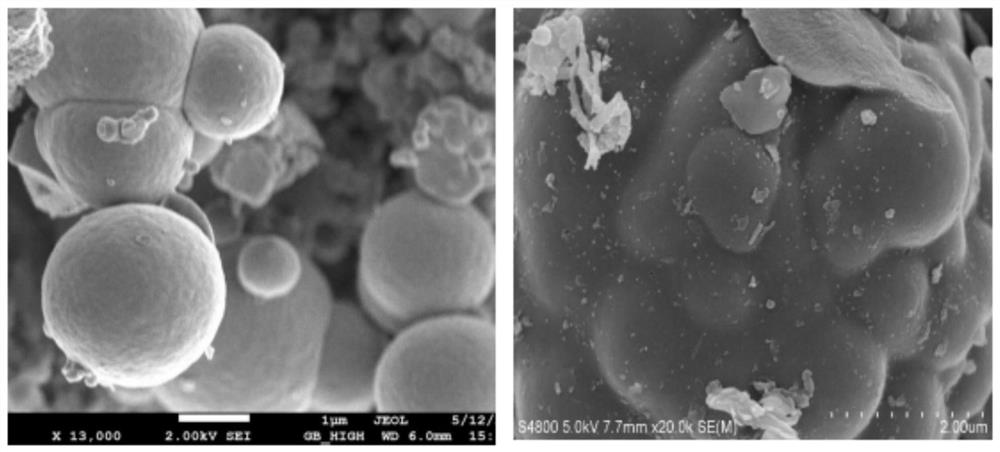

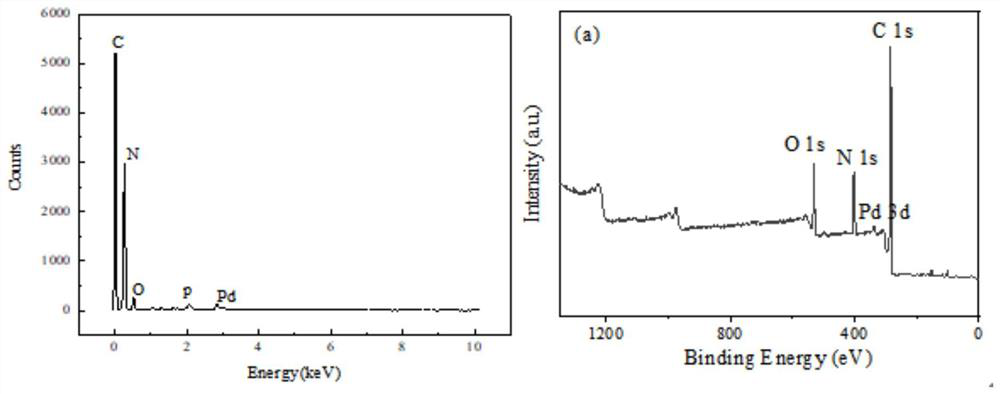

[0041] (2) Put 0.5g of phloroglucinol and 5g of corncob powder into 50mL of deionized water, mix them evenly by ultrasonication for 1h, put the mixed solution into a single-mode microwave synthesizer for hydrolysis, and raise the temperature to 200°C, pressure 10atm, magnetic stirring speed 1500r / min, hydrolysis reaction 2h. After cooling to room temperature, rinse with deionized water and dry. The obtained solid product was calcined in a tube furnace at 650°C for 2 hours to obtain corn-derived heteroatom-containing (N, O, P) carbon microspheres.

[0042] (3) Preparation of carbon microsphere particle electrode: the prepared heterocarbon microspheres were impregnated into PdNO 3 solution, shake for 4 hours, then f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com