Temporary bonding glue for wafer processing, and preparation method and application thereof

A temporary bonding glue and wafer technology, applied in the field of bonding glue, can solve the problems affecting the processing quality and processing efficiency of wafers, edge corrosion of bonding glue, uneven thickness of chips, etc., to achieve good bonding effect, enhance internal The effect of increased cohesion strength, degree of staggered overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

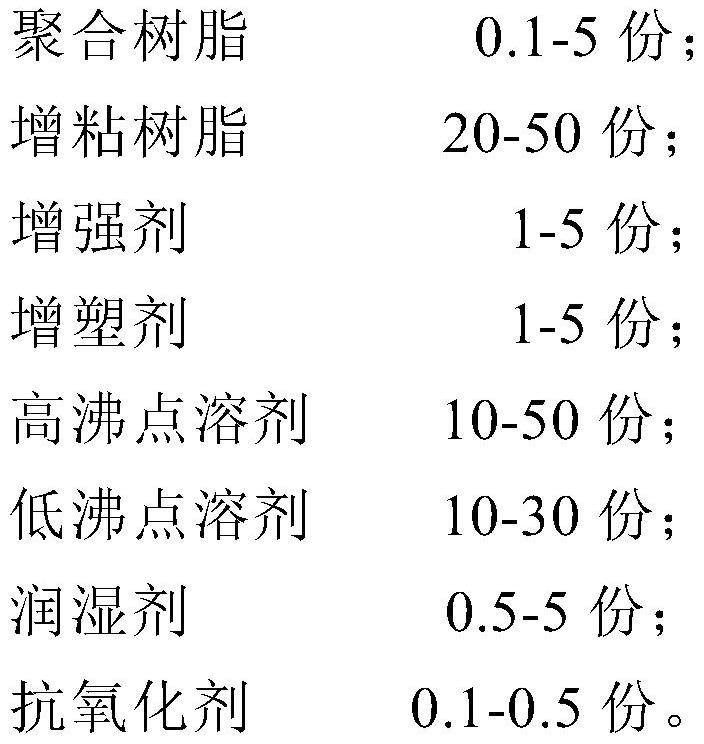

[0048] Examples 1-12 disclose a variety of temporary bonding adhesives for wafer processing, and their components and parts by mass are shown in Table 1.

[0049] Embodiments 1-12 The preparation methods of various temporary bonding adhesives for wafer processing are as follows:

[0050] Step (1): Add a high boiling point solvent and a low boiling point solvent into the stirred tank and stir to mix evenly; the stirring condition is: 70r / min stirring for 5min;

[0051] Step (2): Heat the solution obtained in step (1) to 40°C, add tackifying resin under continuous stirring, and stir until a clear and transparent liquid is formed; the stirring condition is: 80r / min stirring for 50min;

[0052] Step (3): Add plasticizer, wetting agent and antioxidant to the solution obtained in step (2), and stir until a clear and transparent liquid is formed; the stirring condition is: stirring at 80r / min for 40min;

[0053] Step (4): Add polymeric resin to the solution obtained in step (3), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com