Bactericide for industrial cooling water

A cooling water and bactericide technology, applied in biocide, sterilization/microdynamic water/sewage treatment, application, etc., can solve problems such as poor solubility, reduce precipitation and scaling, improve stability, overcome pro- Poor water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of N-alkyl benzimidazole

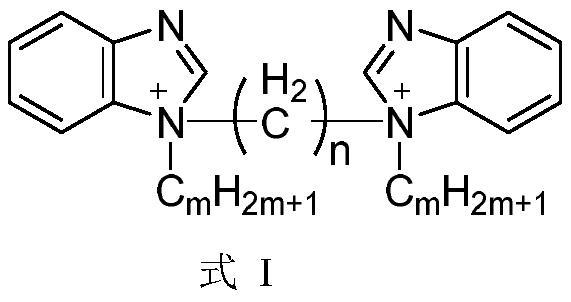

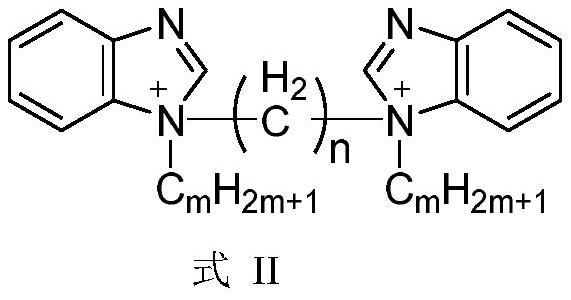

[0037] This quaternary ammonium salt surfactant is made by following equation:

[0038] 1)

[0039] 2)

[0040] 3)

[0041] 4)

[0042] Prepared by the following steps respectively:

[0043] With 1mol (118g) benzimidazole, 1.04mol (259g) n-dodecyl bromide and 15mmol (5g) phase transfer catalyst Bu 4 NBr and toluene were placed in the reactor, stirred and heated to 65°C, and 300mL of 40wt% sodium hydroxide was slowly added dropwise. After the dropwise addition, the temperature was raised to 85°C for 4 hours of reaction; the organic phase was separated, and the water phase was washed with toluene for 3 Once, the organic phases were combined, dried with anhydrous calcium chloride, and distilled under reduced pressure to obtain 0.981mol (281g) of N-n-dodecylbenzimidazole.

[0044] With 1mol (118g) benzimidazole, 1.05mol (217g) brominated n-decane and 15mmol (5g) phase transfer catalyst Bu 4 NBr and tolu...

Embodiment 2

[0047] Embodiment 2: the preparation of benzimidazole quaternary ammonium salt surfactant

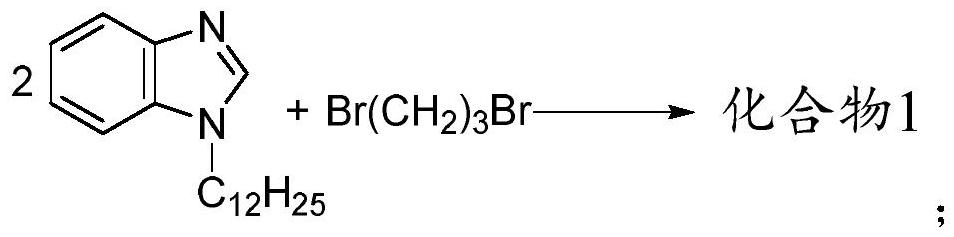

[0048] Compound 1 is prepared by the following reaction equation:

[0049]

[0050] Prepared by the following steps:

[0051] Dissolve 0.1mol (28.7g) of N-dodecylbenzimidazole in 120mL of acetonitrile and place it in a reactor connected to a reflux condenser;

[0052] 0.05mol (10.1g) Br(CH 2 ) 3 Br was placed in a constant pressure dropping funnel, protected by a nitrogen flow, stirred and heated in the reactor until the temperature of the liquid rose to 55°C;

[0053] Open the constant pressure dropping funnel, and drop Br(CH 2 ) 3 Br; after the dropwise addition, heat up to reflux reaction, TLC monitors until the reaction is complete; the developing solution is a mixture of water and methanol in a ratio of 1:3;

[0054] After cooling, acetonitrile was distilled off under reduced pressure to obtain light yellow compound 1.

[0055] Compound 2 is prepared by the following reac...

Embodiment 3

[0083] Embodiment 3: Bactericide for industrial cooling water

[0084] A kind of bactericide for industrial cooling water is made up of 1 part of quaternary ammonium salt surfactant shown in the following table and 1000 parts of polyethylene glycol shown in the following table:

[0085] Table 1 Bactericides for industrial cooling water

[0086] Example 3a Example 3b Example 3c Example 3d Example 3e Example 3f Compound 1 Compound 2 Compound 3 Compound 4 Compound 5 Compound 6 PEG-6 PEG-6 PEG-6 PEG-6 PEG-6 PEG-6 Example 3g Example 3h Example 3i Example 3j Example 3k Example 3l Compound 2 Compound 2 Compound 2 Compound 3 Compound 3 Compound 3 PEG-4 PEG-8 PEG-10 PEG-4 PEG-8 PEG-10

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com