Preparation method and application of palladium cluster catalyst

A catalyst and cluster technology, which is applied in the preparation of noble metal cluster catalysts and its catalytic synthesis of fine organic chemicals, to achieve high product selectivity, improve stability, and overcome agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

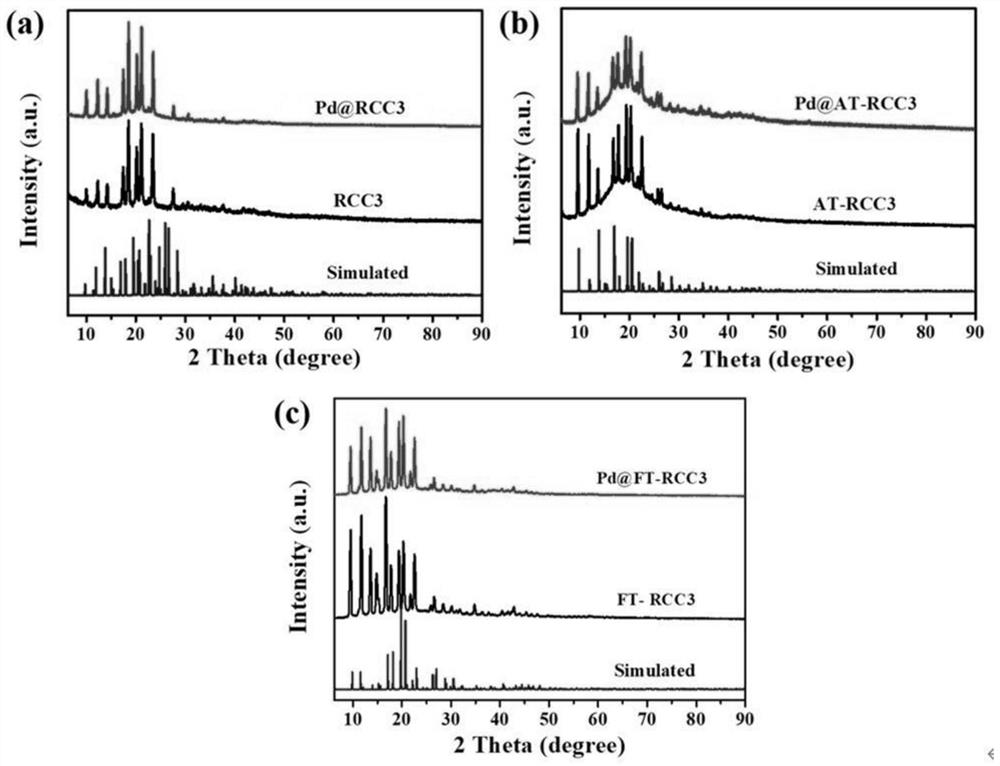

Embodiment 1

[0029] A kind of preparation method of Pd cluster catalyst, concrete method is as follows: 500mg trimesaldehyde, 500mg (1R, 2R)-cyclohexanediamine, 10 μ L CF 3 Add 10mL CH to COOH 2 Cl 2 , stir to dissolve evenly, and let the mixed solution stand at room temperature for 1-7 days, then centrifuge the crystallized solid powder and dissolve it in 50mL CHCl 2 / CH 3 OH mixture (1:1, v / v); after the solution is clarified, add 0.5 g of sodium borohydride and stir continuously at room temperature for 12 hours, and adopt centrifugal separation and vacuum drying at room temperature to obtain a white powdery organic molecular cage RCC3; dissolve 100mg RCC3 in 6mL acetone, let it stand at room temperature for 12 hours, collect crystals, wash with acetone (2×100mL) to obtain organic molecular cage AT-RCC3; dissolve 60mg paraformaldehyde in 10mL CH 3 OH, stirred at 70°C, when the solution was clear, the CH of RCC33 OH solution was added to the above solution, and a white precipitate was ...

Embodiment 2

[0031] A kind of preparation method of Pd cluster catalyst, specific method is as follows: RCC3 molecular cage 100mg among the embodiment 1 is stirred and dispersed in 200mL deionized water, after continuous stirring, dropwise add 22mmol Pd(OAc) 2 10mL of dichloromethane solution, stirring continuously for 12h; in ice-water bath, add 4mg of newly prepared NaBH dropwise 4 40 mL of the aqueous solution was stirred vigorously for 12 h, collected by centrifugation, washed 5 times with water, and dried in vacuum at room temperature for 3 h to obtain the Pd cluster-supported catalyst Pd@RCC3.

Embodiment 3

[0033] A kind of preparation method of Pd cluster catalyst, specific method is as follows: the AT-RCC3 molecular cage 120mg among the embodiment 1 is stirred and dispersed in 200mL deionized water, after continuous stirring, dropwise add 22mmol Pd(OAc) 2 10mL of dichloromethane solution, stirring continuously for 12h; in ice-water bath, add 4mg of newly prepared NaBH dropwise 4 40 mL of the aqueous solution was stirred vigorously for 12 h, collected by centrifugation, washed 5 times with water, and dried in vacuum at room temperature for 3 h to obtain the Pd cluster-supported catalyst Pd@AT-RCC3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com