Two-component pouring sealant as well as preparation method and application thereof

A potting glue, two-component technology, applied in the field of potting glue, can solve the problems of unrepairable recycling, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

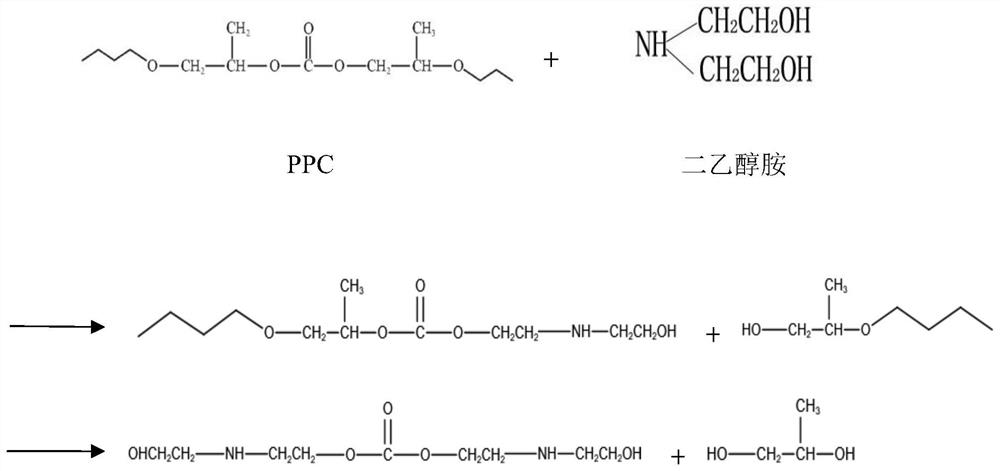

Method used

Image

Examples

Embodiment 1

[0038] Example 1 of the present application provides the first method for preparing a two-component encapsulant, including the preparation of component A and component B.

[0039] (1) Preparation of component A

[0040] Calculated in parts by mass, vacuum dehydrate 60 parts of polypropylene carbonate with a molecular weight of 1000g / mol and 40 parts of polypropylene carbonate with a molecular weight of 2000g / mol at 110-120°C for 2-3 hours, then lower the temperature to 60-70°C , add 0.08 parts of organometallic catalyst stannous octoate, add 25 parts of isophorone diisocyanate and gradually raise the temperature to 75-85°C for reaction within 30 minutes, pass nitrogen protection during the reaction, and test the NCO% value, the NCO% value When the set value is reached, the reaction is stopped, and anti-aging agent 2,6-di-tert-butyl-4-methylphenol is added to obtain component A, and the set value is within the range of 5% to 15%.

[0041] (2) Preparation of component B

[004...

Embodiment 2

[0044] Example 2 of the present application provides a second method for preparing a two-component encapsulant, including the preparation of component A and component B.

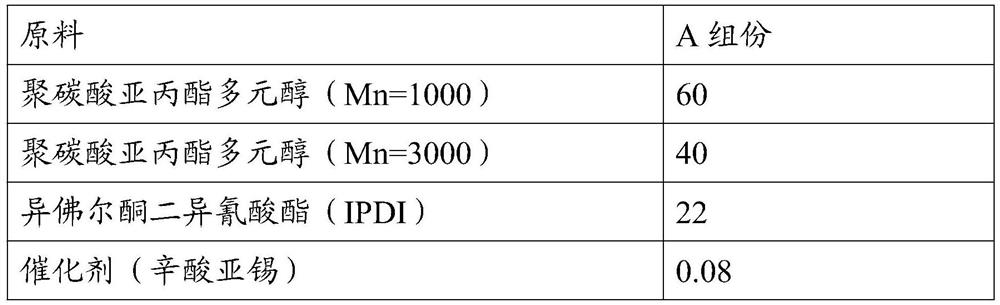

[0045] The difference with Example 1 is that the preparation raw material ratio of A component and B component is:

[0046]

[0047]

Embodiment 3

[0049] Example 3 of the present application provides a third method for preparing a two-component potting compound, including the preparation of component A and component B.

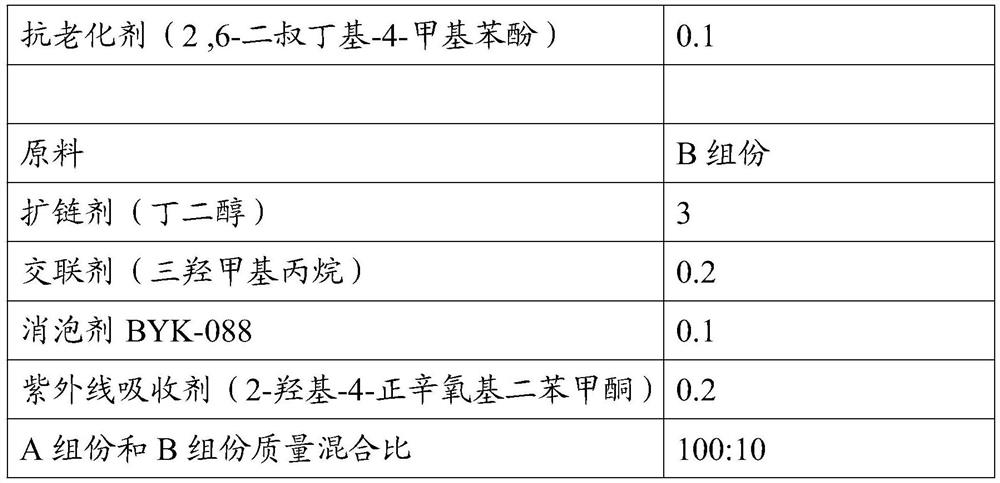

[0050] The difference with Example 1 is that the preparation raw materials of A component and B component are:

[0051] raw material Component A Polypropylene carbonate polyol (Mn=2000) 60 Polypropylene carbonate polyol (Mn=3000) 40 Toluene diisocyanate (MDI) 20 Catalyst (Stannous Octanoate) 0.08 Anti-aging agent (2,6-di-tert-butyl-4-methylphenol) 0.1 raw material Component B Chain extender (butanediol) 3 Crosslinking agent (trimethylolpropane) 0.5 Defoamer BYK-A530 0.1 UV absorber (2-hydroxy-4-n-octyloxybenzophenone) 0.2 A component and B component mass mixing ratio 100:15

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com