A kind of biological scaffold, its molding method and application

A bio-stent and molding method technology, applied in tissue regeneration, prosthesis, medical science, etc., can solve the problems of high energy consumption, poor promotion, complicated devices, etc., and achieve the effect of reducing production cost and production difficulty, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

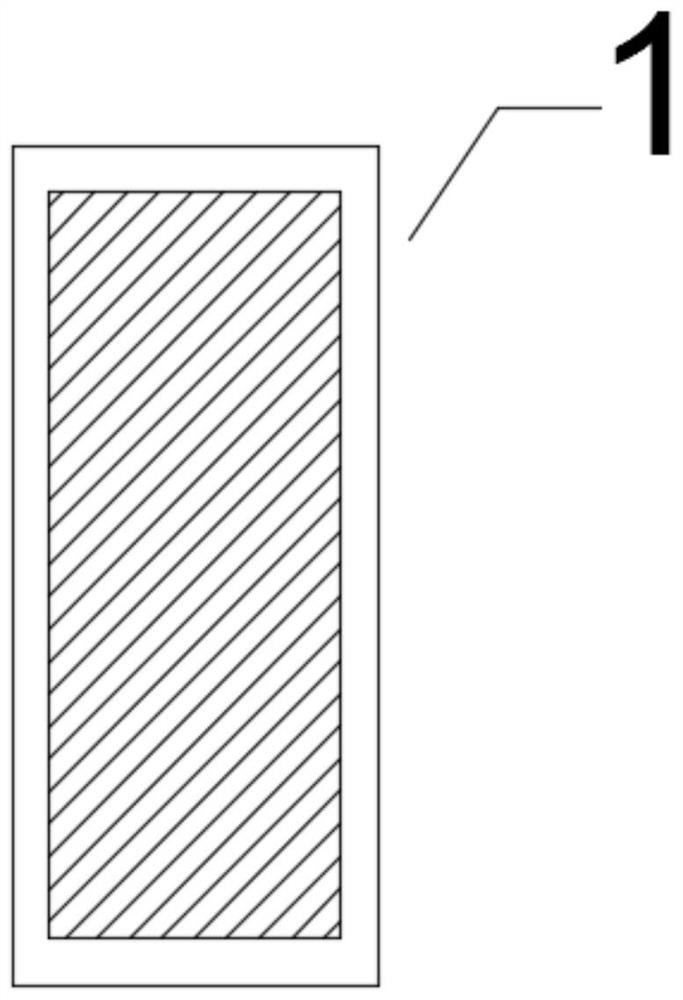

[0034] The present embodiment provides a method for forming a biological scaffold, comprising the following steps:

[0035] (1) mix the acid-soluble collagen dry powder, chitosan dry powder and hyaluronic acid dry powder, and swell in 0.05mol / L acetic acid aqueous solution to obtain raw material slurry; wherein, the total amount of acid-soluble collagen and chitosan is The concentration is 3 wt.%, and the concentration of hyaluronic acid is 0.1 wt.%;

[0036] (2) Use liquid nitrogen to pre-freeze the raw material slurry, and transfer the raw material slurry to the cylindrical metal mold 1 by injection, and lower the entire metal mold to the upper surface of the liquid nitrogen 2mm, without control Decrease the speed and stay for 15 minutes to keep the entire metal mold at a constant temperature, and pre-freeze the biological scaffold after completion;

[0037] (3) drying the pre-frozen biological scaffold, and the drying includes 5 stages in turn, which are:

[0038] (1) Und...

Embodiment 2

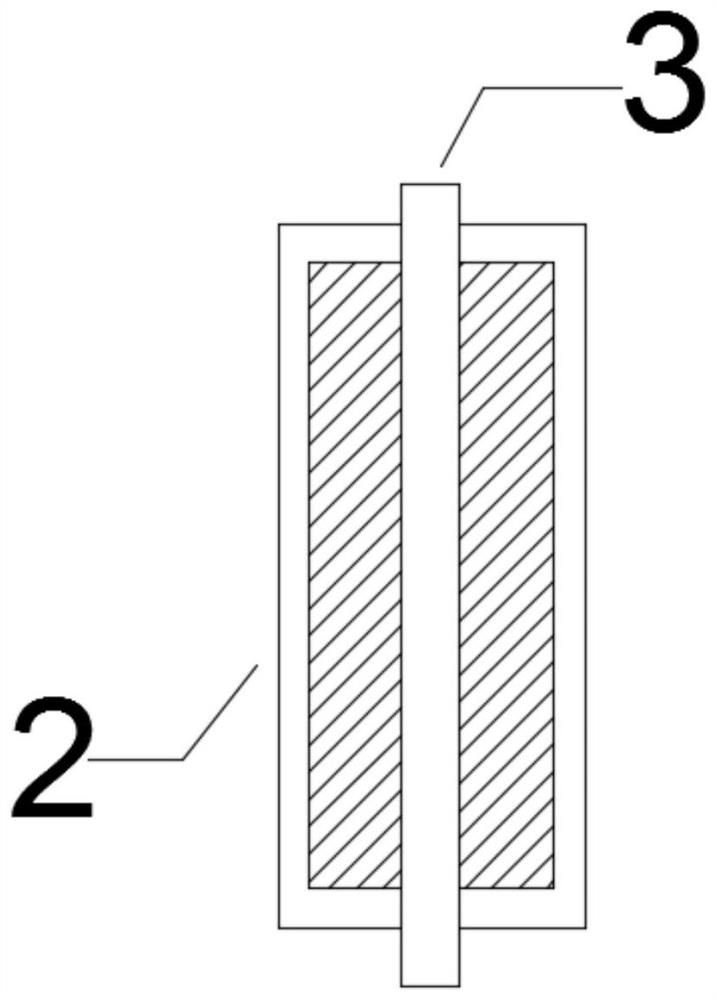

[0045] The present embodiment provides a method for forming a biological scaffold, comprising the following steps:

[0046] (1) mix the acid-soluble collagen dry powder and chondroitin sulfate dry powder, and swell in 0.05mol / L acetic acid aqueous solution to obtain raw material slurry; wherein, the concentration of acid-soluble collagen is 10wt. The concentration is 2wt.%;

[0047] (2) Use liquid nitrogen to pre-freeze the raw material slurry, and transfer the raw material slurry to the circular tubular metal mold 2 by injection, and lower the entire metal mold to the upper surface of the liquid nitrogen 20mm, without control Decrease the speed and stay for 120min to keep the entire metal mold at a constant temperature. After completion, take out and pull out the central column 3 to obtain a pre-freezing biological scaffold;

[0048] (3) drying the pre-frozen biological scaffold, and the drying includes 5 stages in turn, which are:

[0049] (1) Under the condition of -35℃, ...

Embodiment 3

[0056] The present embodiment provides a method for forming a biological scaffold, comprising the following steps:

[0057] (1) Mix chitosan dry powder and dermatan sulfate dry powder, and swell in 0.05mol / L acetic acid aqueous solution to obtain raw material slurry; wherein, the concentration of chitosan is 7wt.%, and the concentration of dermatan sulfate is 1wt.% ;

[0058] (2) Use liquid nitrogen to pre-freeze the raw material slurry, transfer the raw material slurry to a cylindrical metal mold by injection, and lower the entire metal mold to 10mm on the upper surface of the liquid nitrogen without controlling the drop speed, and stay for 70min to keep the entire metal mold at a constant temperature, and pre-freeze the biological scaffold after completion;

[0059] (3) drying the pre-frozen biological scaffold, and the drying includes 5 stages in turn, which are:

[0060] (1) Under the condition of -35℃, freeze for 15min;

[0061] (2) Freeze-drying for 830min at -9℃ and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com