Layer-by-layer deposited antibacterial healing-promoting soluble microneedle patch and preparation method thereof

A soluble, micro-needle sticker technology, applied in micro-needle, antibacterial, antifungal and other directions, can solve the problems of needle body retention, single component, easy needle breakage, etc., to reduce dosage, improve mechanical properties, reduce The effect of drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

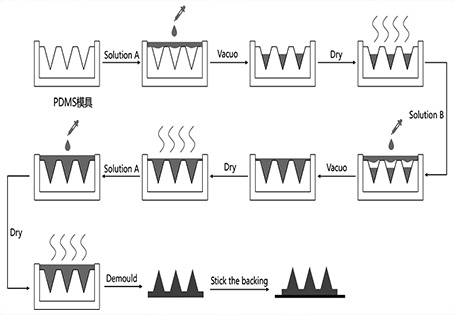

[0021] Such as figure 1 As shown, the preparation method of the antibacterial and healing-promoting soluble microneedle patch in the present invention comprises the following steps:

[0022] (1) The configuration of the precursor solution for promoting healing and moisturizing: add sodium alginate into deionized water at 70~80°C, stir well until it is completely dissolved, after the temperature of the solution drops to 40°C, add hyaluronic acid, and stir well until the solution is dissolved Clarified to obtain the healing and moisturizing precursor A;

[0023] (2) Configuration of antibacterial and anti-inflammatory layer solution: add polyvinyl alcohol to deionized water at 90~95°C, stir until it dissolves into a uniform solution, and when the temperature of the solution drops to 50~60°C, add chitosan quaternary ammonium in turn Salt, polyhexamethylene guanidine hydrochloride and gelatin are fully stirred until the solution is evenly mixed to obtain antibacterial and anti-in...

Embodiment 1

[0027] A preparation method for layer-by-layer deposition of an antibacterial and healing-promoting soluble microneedle patch, the method comprising the following steps:

[0028] (1) Configuration of the healing and moisturizing precursor solution: Add 2 parts of sodium alginate into deionized water at 70~80°C, stir until it is completely dissolved. After the temperature of the solution drops to 40°C, add 5 parts of hyaluronic acid, fully Stir until the solution is clear to obtain the healing and moisturizing precursor A;

[0029] (2) Configuration of the antibacterial and anti-inflammatory layer solution: add 6 parts of polyvinyl alcohol to deionized water at 90~95°C, stir until it dissolves into a uniform solution, and when the temperature of the solution drops to 50~60°C, add 5 parts of shell polysaccharide quaternary ammonium salt, 2 parts of polyhexamethyleneguanidine hydrochloride and 1 part of gelatin, fully stirred until the solution is evenly mixed to obtain antibacte...

Embodiment 2

[0033] (1) Configuration of the healing and moisturizing precursor solution: Add 2 parts of sodium alginate into deionized water at 70~80°C, stir well until it is completely dissolved. After the temperature of the solution drops to 40°C, add 6 parts of hyaluronic acid, fully Stir until the solution is clear to obtain the healing and moisturizing precursor A;

[0034] (2) Configuration of the antibacterial and anti-inflammatory layer solution: add 4 parts of polyvinyl alcohol to deionized water at 90~95°C, stir until it dissolves into a uniform solution, and when the temperature of the solution drops to 50~60°C, add 6 parts of shell polysaccharide quaternary ammonium salt, 3 parts of polyhexamethyleneguanidine hydrochloride and 1 part of gelatin, fully stirred until the solution is evenly mixed to obtain antibacterial and anti-inflammatory precursor solution B;

[0035](3) Preparation of layer-by-layer deposition of antibacterial and healing-promoting soluble microneedles: extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Needle length | aaaaa | aaaaa |

| Needle length | aaaaa | aaaaa |

| Needle length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com