Method for dyeing green by vegetable dye through one-bath process

A plant dye, green technology, applied in the field of plant dye one-bath dyeing green, can solve the problems of cumbersome modification process of plant dye, poor color fastness of textiles, loss of natural characteristics, etc., to achieve good production quality controllability, color High fastness and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

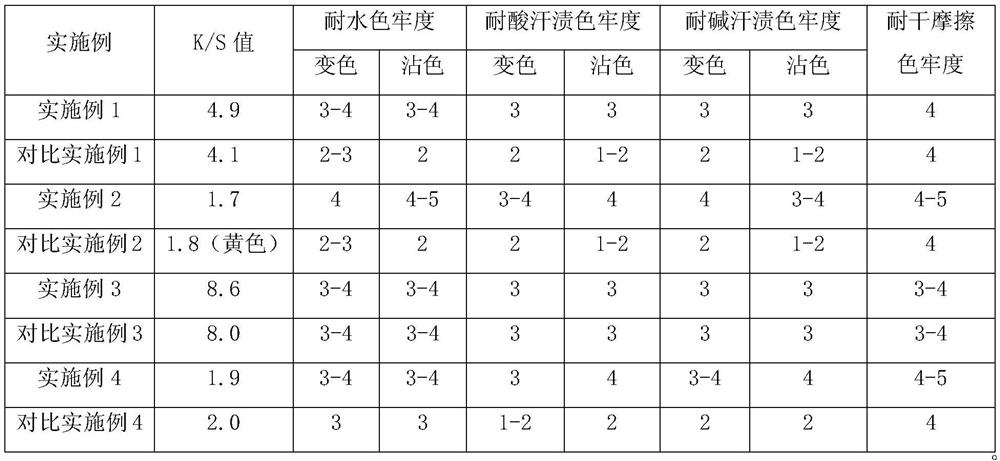

Examples

Embodiment 1

[0044] Embodiment 1: one-bath method of the present invention dyes dark green mulberry silk fabric

[0045] (1) Preparation of plant leuco indigo solution: 2500g of soda ash and 2000g of glucose are dissolved in 30L and 10L of water respectively, then 200mL of rice wine, 1000g of cyanine and glucose solution are added to the soda ash solution, and the cyanine is kneaded to make it Reduce and dissolve, stir evenly, and let stand for 30min.

[0046] (2) Preparation of plant indigo leuco acid solution:

[0047] Add 12g of glucose and 600g of natural additives to 4L of water, stir evenly, then slowly add 4L of plant leuco indigo solution into it under high-speed stirring, and stir for 10 minutes under sealed conditions. At this time, the pH value is 5.2.

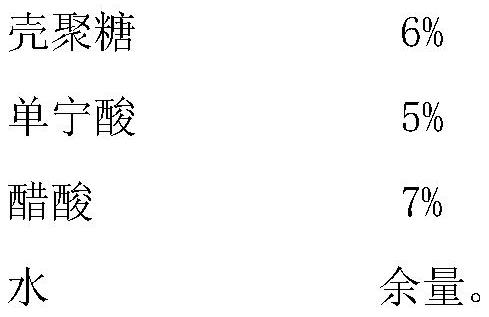

[0048] Natural aids consist of the following ingredients:

[0049]

[0050] (3) Preparation of color matching vegetable dye solution:

[0051] Add 70g of sumac extract powder, 80g of tea extract powder, 300g of the aforeme...

Embodiment 2

[0060] Embodiment 2: one-bath method of the present invention dyes light green cotton / linen fabric

[0061] (1) Preparation of Plant Leuco Indigo Solution:

[0062] Dissolve 1000g of caustic soda and 1300g of Baowen with 30L and 10L of water respectively, then add 100mL of sorghum wine, 5000g of indigo naturalis, and sodium hydrochloride solution into the caustic soda solution, knead the indigo naturalis to reduce and dissolve, stir evenly, and let it stand for 30 minutes.

[0063] (2) Preparation of plant indigo leuco acid solution:

[0064] Add 8 g of sodium hydrosulfite and 400 g of natural additives into 4 L of water, stir evenly, and slowly add 4 L of plant leuco indigo solution into it under high-speed stirring, and stir for 10 minutes in a sealed manner. At this time, the pH value is 5.0.

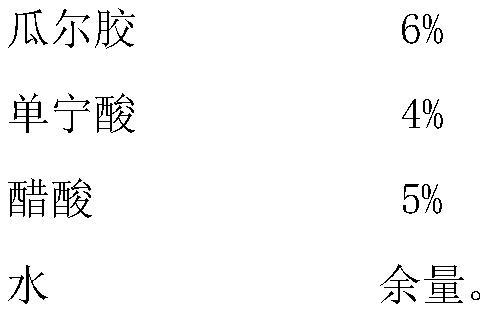

[0065] Natural aids consist of the following ingredients:

[0066]

[0067] (3) Preparation of color matching vegetable dye solution:

[0068] Add 200g of pomegranate peel extr...

Embodiment 3

[0077] Embodiment 3: one-bath method dyeing dark green wool of the present invention

[0078] (1) Preparation of Plant Leuco Indigo Solution: Same as Example 1.

[0079] (2) Preparation of plant indigo leuco acid solution: same as in Example 1, 2 L was prepared.

[0080] (3) Preparation of color matching plant dye solution: 30g of yam extract powder, 20g of tea extract powder, 20g of lotus pod extract powder, 30g of natural additives, 2g of glucose, add a small amount of water and stir into a paste, add warm water at about 80°C and stir, After dissolving, add 6g of alum aqueous solution and stir evenly to prepare 1L of color matching plant dye solution.

[0081] (4) Preparation of plant dye green dyeing solution:

[0082] Add the above color-blocking vegetable dye solution into the stirring vegetable indigo leuco acid solution, and mix evenly.

[0083] (5) One-bath green dyeing process of vegetable dyes:

[0084] Immerse 100g of wool fabric in the above dyeing solution, sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com