Bistable photonic crystal color electronic ink material and preparation and application thereof

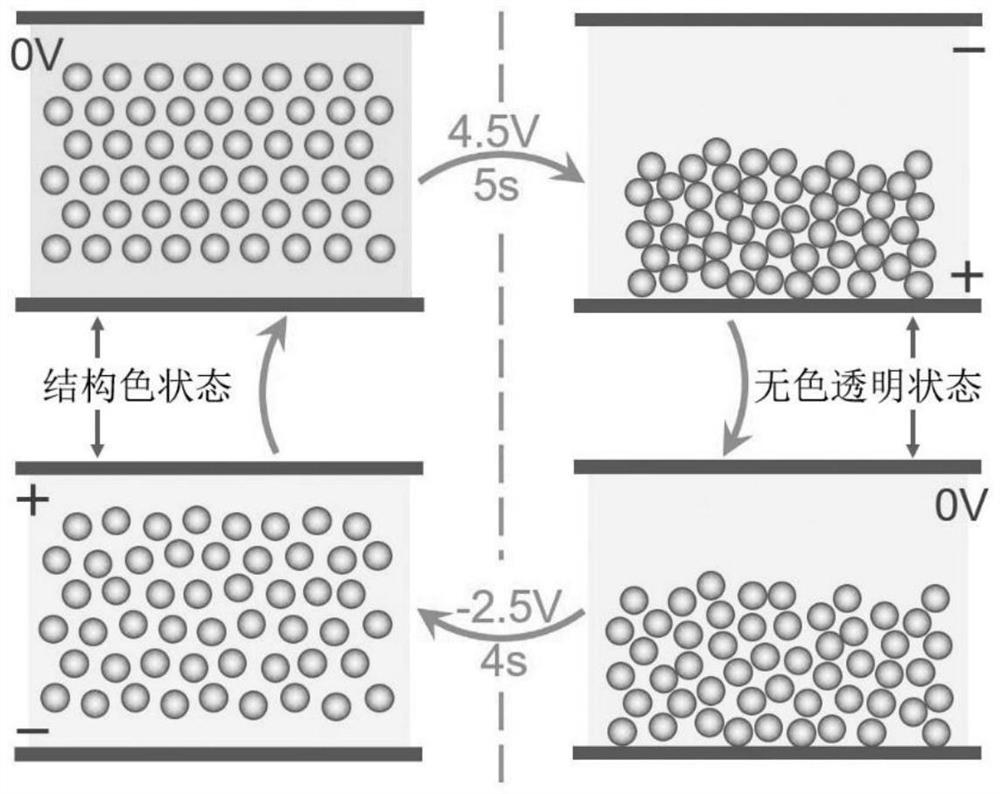

A technology of electronic ink and photonic crystal, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems that electronic ink cannot realize stable display without electric field, achieve the advantages of color saturation and permeability, and controllable electric field control The effect of high stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

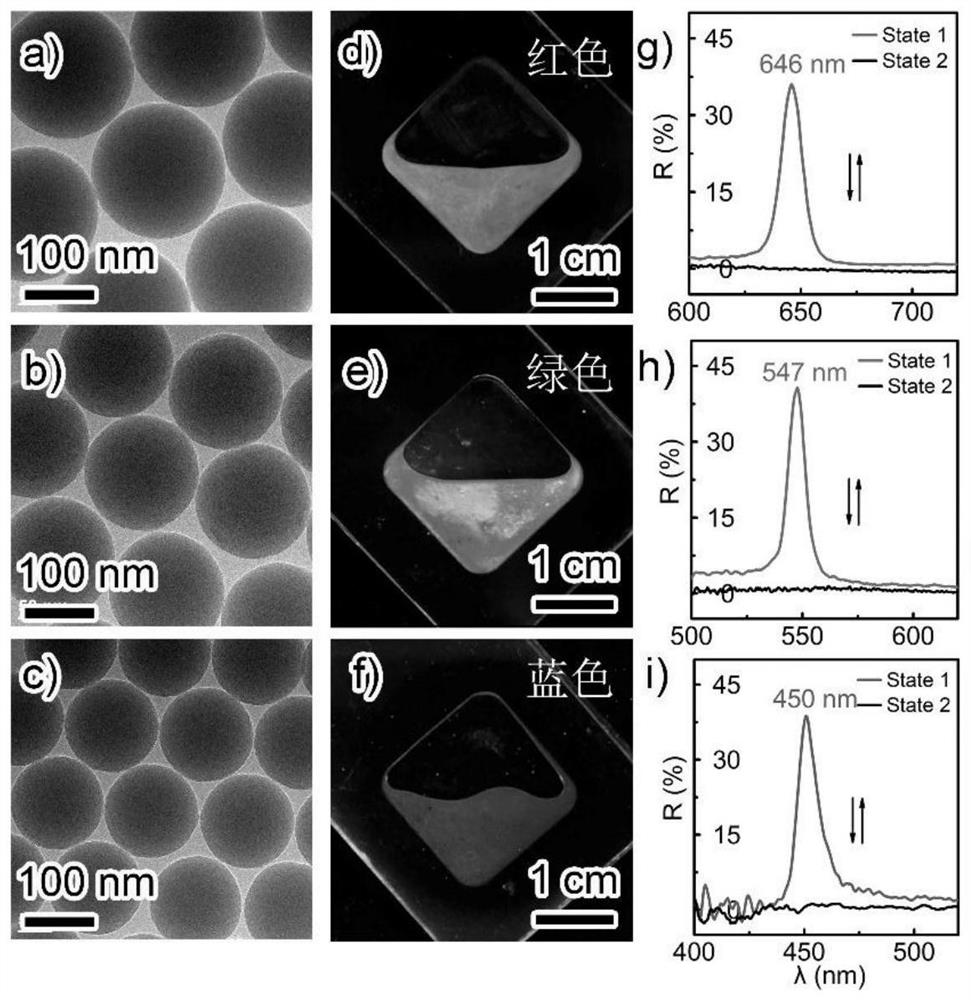

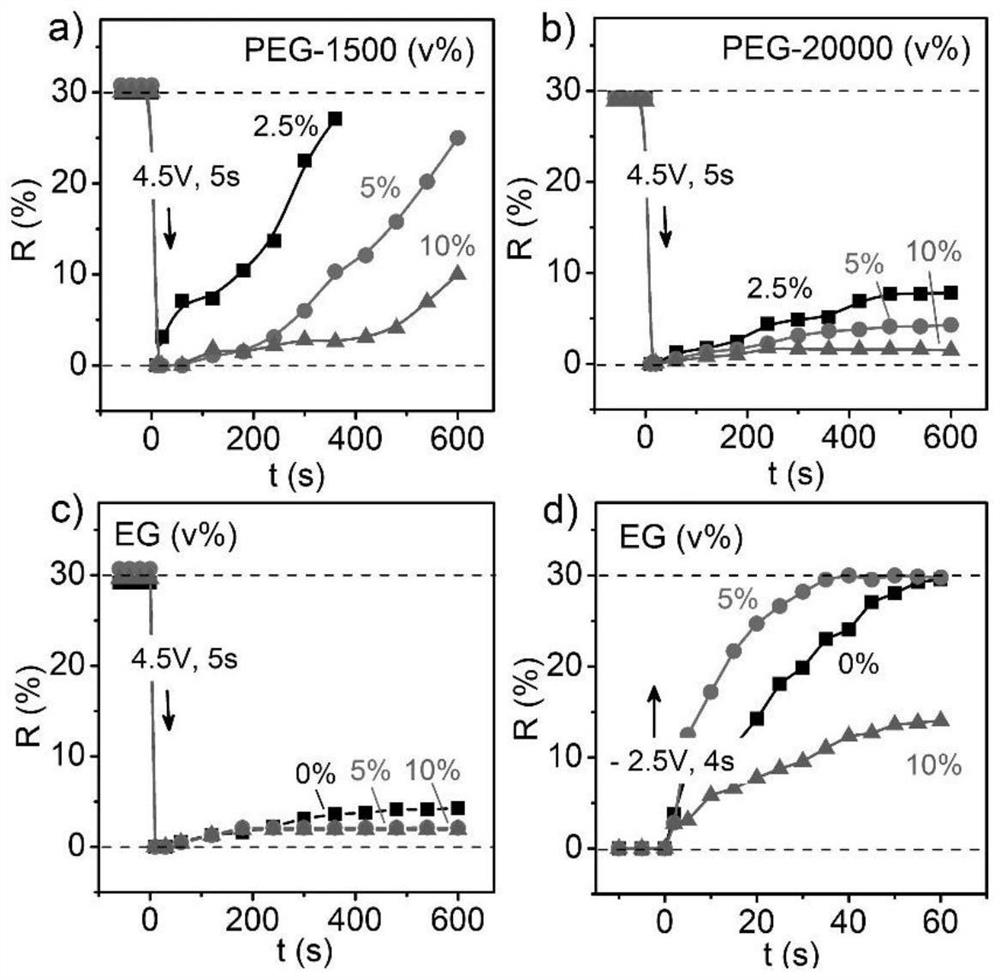

[0052] Example 1 Red SiO regulated by electric field 2 Preparation of PCb-EG-PEG bistable photonic crystal color electronic ink material

[0053] Such as figure 2 a, 2d, 2g shown, using Monodisperse SiO with an average particle size of 199 nm prepared by the method 2 Colloidal particles, disperse 30 μL of the above colloidal particles in 1100 μL ethanol solution, add 5 μL polyethylene glycol with a molecular weight of 20,000, 60 μL propylene carbonate and 5 μL ethylene glycol, and ultrasonically mix to form a homogeneous solution. The mixed solution was heated in an oven at 90° C. for 2 hours to volatilize and remove ethanol in the solution, and 100 μL of a bistable photonic crystal color electronic ink material with a red structural color was prepared.

[0054] The prepared electronic ink material is packaged in two pieces of ITO conductive glass, and a 50 μm double-sided adhesive is used as a spacer to prepare a red photonic crystal electronic ink display device with bi...

Embodiment 2

[0056] Embodiment 2 Green SiO regulated by electric field 2 Preparation of PCb-EG-PEG bistable photonic crystal color electronic ink material

[0057] Such as figure 2 b, as shown in 2e and 2h, using Monodisperse SiO with an average particle size of 169 nm prepared by the method 2 Colloidal particles, disperse 30 μL of the above colloidal particles in 1100 μL ethanol solution, add 5 μL polyethylene glycol with a molecular weight of 20,000, 60 μL propylene carbonate and 5 μL ethylene glycol, and ultrasonically mix to form a homogeneous solution. The mixed solution was heated in an oven at 90° C. for 2 hours to volatilize and remove the ethanol in the solution, and 100 μL of a bistable photonic crystal color electronic ink material with a green structural color was prepared.

[0058] The prepared electronic ink material is packaged in two pieces of ITO conductive glass, and a 50 μm double-sided adhesive is used as a spacer to prepare a green photonic crystal electronic ink ...

Embodiment 3

[0060] Example 3 Blue SiO regulated by electric field 2 Preparation of PCb-EG-PEG bistable photonic crystal color electronic ink material

[0061] Such as figure 2 As shown in c, 2f, 2i, using Monodisperse SiO with an average particle size of 138 nm prepared by the method 2 Colloidal particles, disperse 30 μL of the above colloidal particles in 1100 μL ethanol solution, add 5 μL polyethylene glycol with a molecular weight of 20,000, 60 μL propylene carbonate and 5 μL ethylene glycol, and ultrasonically mix to form a homogeneous solution. The mixed solution was heated in an oven at 90° C. for 2 hours to volatilize and remove ethanol in the solution, and 100 μL of bistable photonic crystal color electronic ink material with blue structural color was prepared.

[0062] The prepared electronic material ink is packaged in two pieces of ITO conductive glass, and a 50 μm double-sided adhesive is used as a spacer to prepare a blue photonic crystal electronic ink display device wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com