Cultivation method for realizing symbiosis of fish and grass by utilizing biogas slurry

A breeding method and biogas slurry technology, applied in the direction of chemical instruments and methods, botany equipment and methods, applications, etc., can solve the problems of polluting the surrounding environment, complex operation, high cost, etc., and achieve low operating cost, low infrastructure investment, and management convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

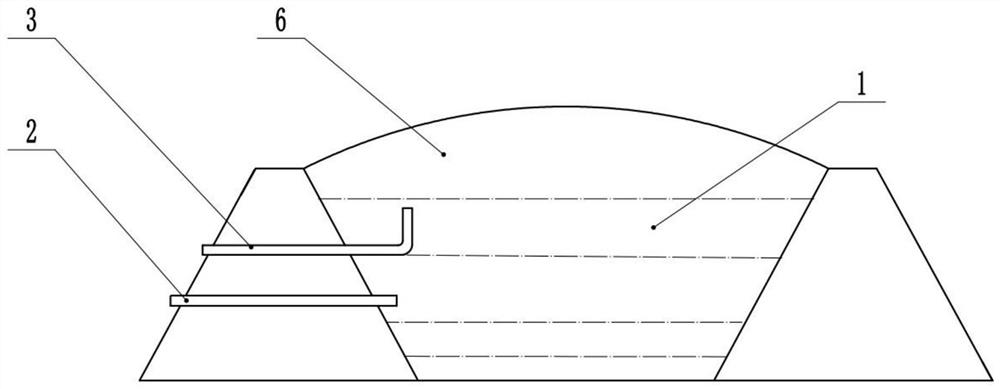

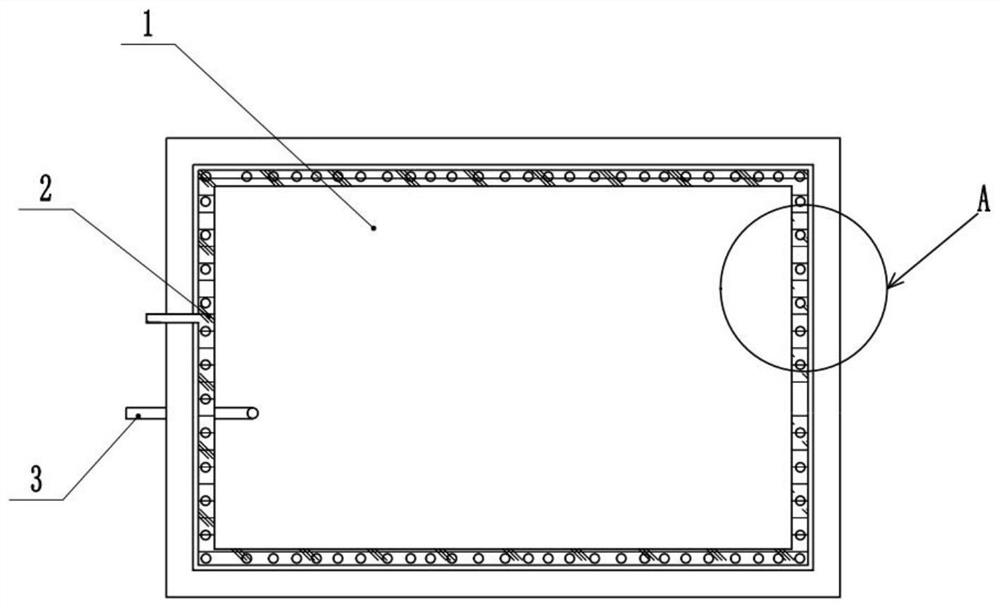

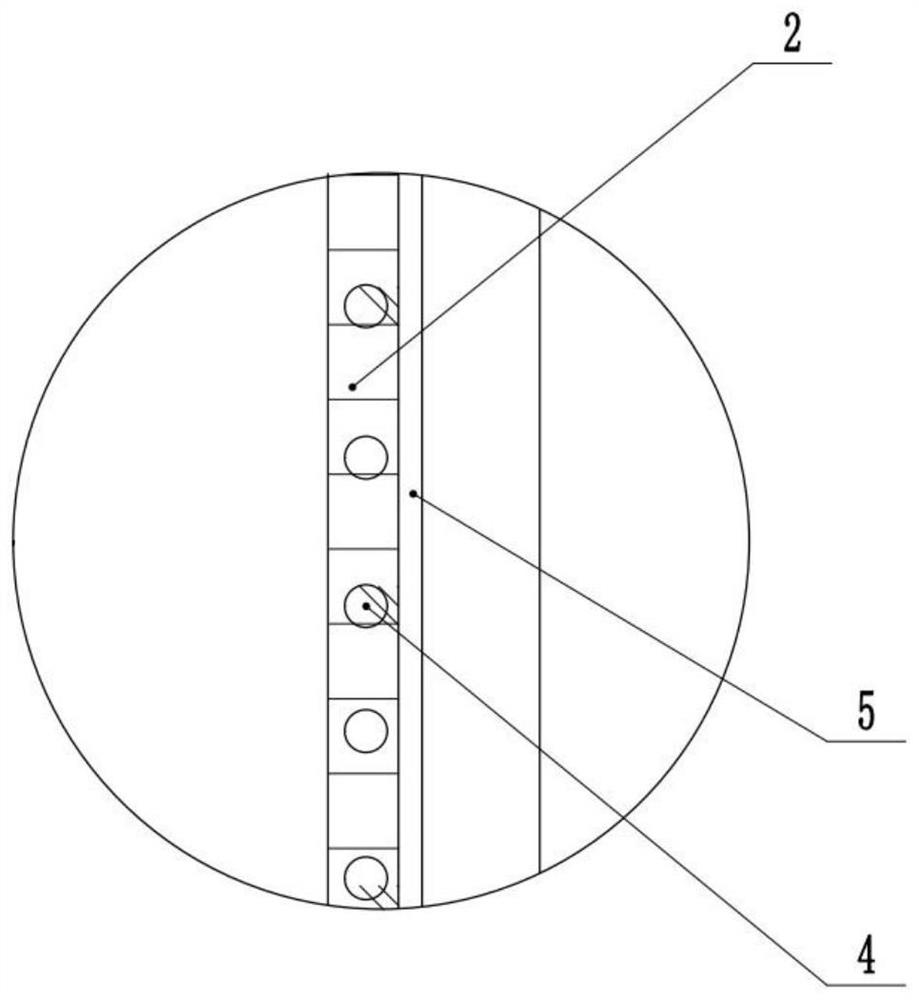

[0022] Please refer to figure 1 , a terminal purification and utilization technology of foxtail fish pond tail water, comprising the following steps:

[0023] 1) A fish pond is prefabricated. The location of the fish pond needs to be located in a mild climate, good lighting conditions, and no pollution; the fish pond 1 has a ridge height of 1.2 meters and an effective water storage depth of 0.8 to 1.0 meters. The upper part of one end is provided with a tail water inlet pipe of the fish pond, and the other end of the upper part of the fish pond is provided with a water outlet for controlling the water level. In order to shade in summer and keep warm in winter, the water temperature is controlled at 18-32°C to ensure the normal growth of foxtail algae;

[0024] 2) After the completion of the fish pond, plant foxtail algae on the bottom of the pond. After the foxtail algae survive, gradually add water as the foxtail algae grows to a water level of 1.0 meters. In summer, install...

Embodiment 2

[0028] The difference between this embodiment and the above-mentioned embodiment is: the fish pond 1 tail water that passes into the foxtail algae fish pond 1 continuously through the fish pond 1 tail water inlet 20 every day 24 hours is less than 80 meters 3 , The water quality of fish pond 1 tail water is: suspended solids: 150~300mg / L, total nitrogen: 40~80mg / L, CODcr: 120~300mg / L, ammonia nitrogen: 3~5mg / L, total phosphorus: 12.0~25.0mg / L, after the suspended solids, organic matter, total N, CODcr, ammonia nitrogen and total phosphorus of the tail water of fish pond 1 that are fed into each day are absorbed and absorbed by the roots of Foxtail algae, they are discharged through the water outlet 20 that controls the water level, and the discharged The water quality is suspended solids: 10mg / L, total nitrogen: 1.3mg / L, CODcr: 18mg / L, ammonia nitrogen: 1.2mg / L, and total phosphorus: 0.26mg / L, meeting the Class IV standard for surface water discharge.

[0029] In the present ...

Embodiment 3

[0032] The difference between this embodiment and the foregoing embodiment is that it includes the following steps:

[0033] The tail water of fish pond 1 that is continuously fed into the foxtail algae fish pond 1 through the tail water inlet of fish pond 1 is less than 120 m3, and the water quality of fish pond 1 tail water is: suspended solids: 100-280mg / L , Total nitrogen: 35~80mg / L, CODcr: 100~280mg / L, ammonia nitrogen: 3~4.5mg / L, total phosphorus: 10.0~22.0mg / L, and suspended matter in the tail water of 1 fish pond fed daily , organic matter, total N, CODcr, ammonia nitrogen and total phosphorus are absorbed and utilized by the roots of Foxtail Algae, and then discharged through the water outlet that controls the water level. The water quality of the discharged water is suspended solids: 10mg / L, total nitrogen: 1.1mg / L , CODcr: 15mg / L, ammonia nitrogen: 1.0mg / L, total phosphorus: 0.21mg / L, meeting Class IV standards for surface water discharge.

[0034] In the present e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com