Preparation method of triketone dehydrogenation product

A triketone and dehydrogenation technology, applied in the field of preparation of triketone dehydrogenates, can solve the problems of large environmental pollution and low efficiency, and achieve the advantages of reducing side reactions, improving operating conditions, excellent stereoselectivity and regioselectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

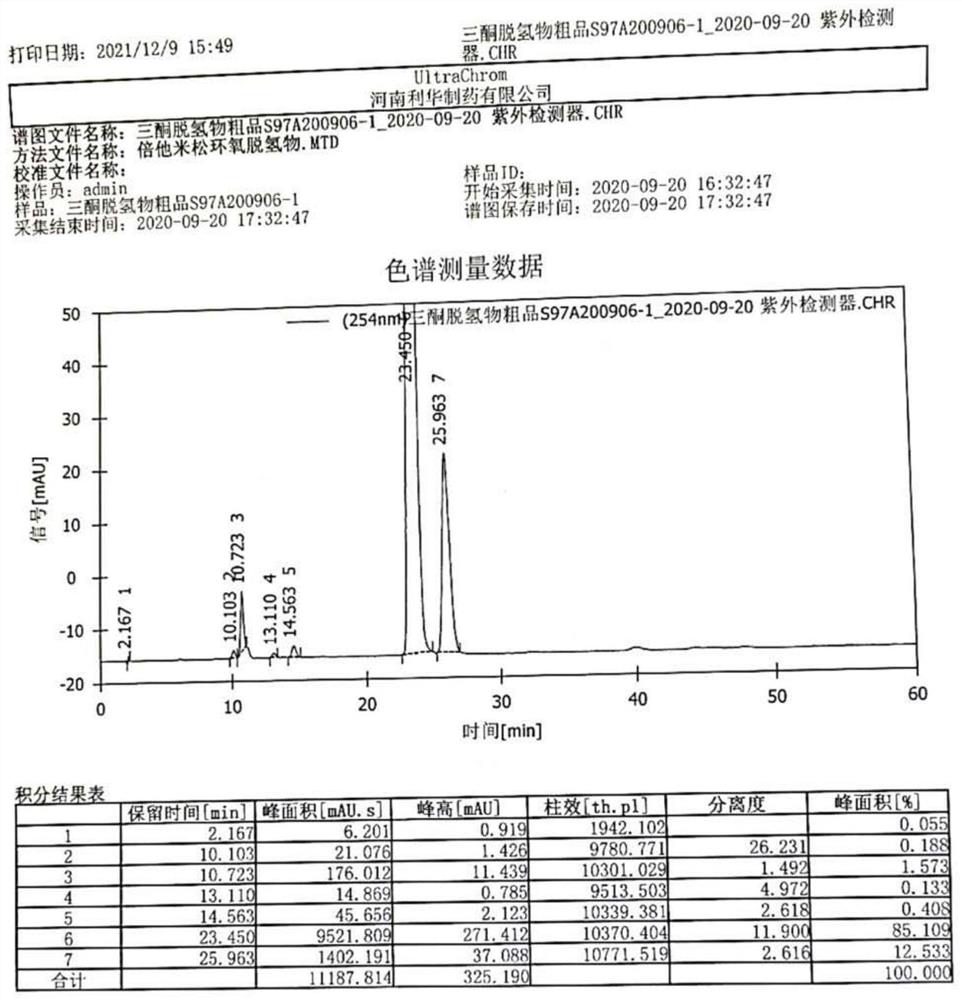

Examples

Embodiment 1

[0051] S11, mixing the triketone and water with a mass ratio of 1:2, then stirring and beating at a stirring speed of 100r / min, the stirring and beating time is 60min, to obtain a slurry;

[0052] Add polyether defoamer dispersant to the slurry, and the mass ratio of slurry to dispersant is 1:0.01. After stirring and mixing, heat up to 121°C to sterilize for 25 minutes, then cool down to room temperature to obtain triketone slurry;

[0053] S12, first add 4% methanol to the fermentation culture liquid, and after 1 hour, put the processed slurry into the fermentation culture liquid of Arthrobacter simplex twice, and the total concentration of the slurry is 3% of the fermentation culture liquid, wherein , the first feeding amount accounted for 20% of the total feeding amount, after 24 hours, the remaining slurry was added, and cultured at 30°C and 150 r / min for 48 hours to obtain triketone dehydrogenation.

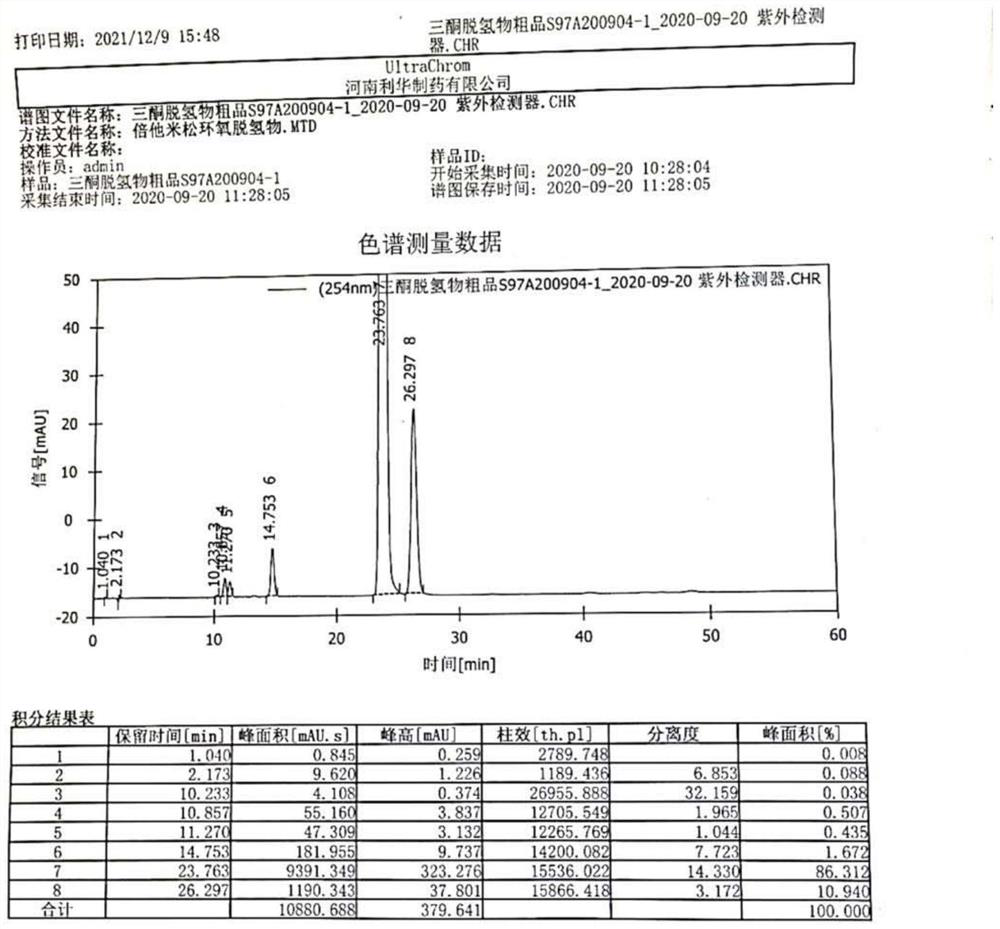

Embodiment 2

[0055] S21, mixing the triketone and water at a mass ratio of 1:3, then stirring and beating at a stirring speed of 150r / min, the stirring and beating time is 20min, to obtain a slurry;

[0056] Add Tween 80 dispersant to the slurry, and the mass ratio of slurry to dispersant is 1:0.05. After stirring and mixing, heat up to about 121°C for sterilization for 25 minutes, and then cool down to room temperature to obtain a triketone slurry;

[0057] S22, first add 5% ethanol to the fermentation culture liquid, after 1h, put the processed slurry into the fermentation culture liquid of Arthrobacter simplex in 2 times, the total concentration of the slurry is 3% of the fermentation culture liquid, wherein , the first feeding amount accounted for 40% of the total feeding amount, after 30h, the remaining slurry was added, and cultivated for 32h under the conditions of 32°C and 150r / min to obtain triketone dehydrogenation.

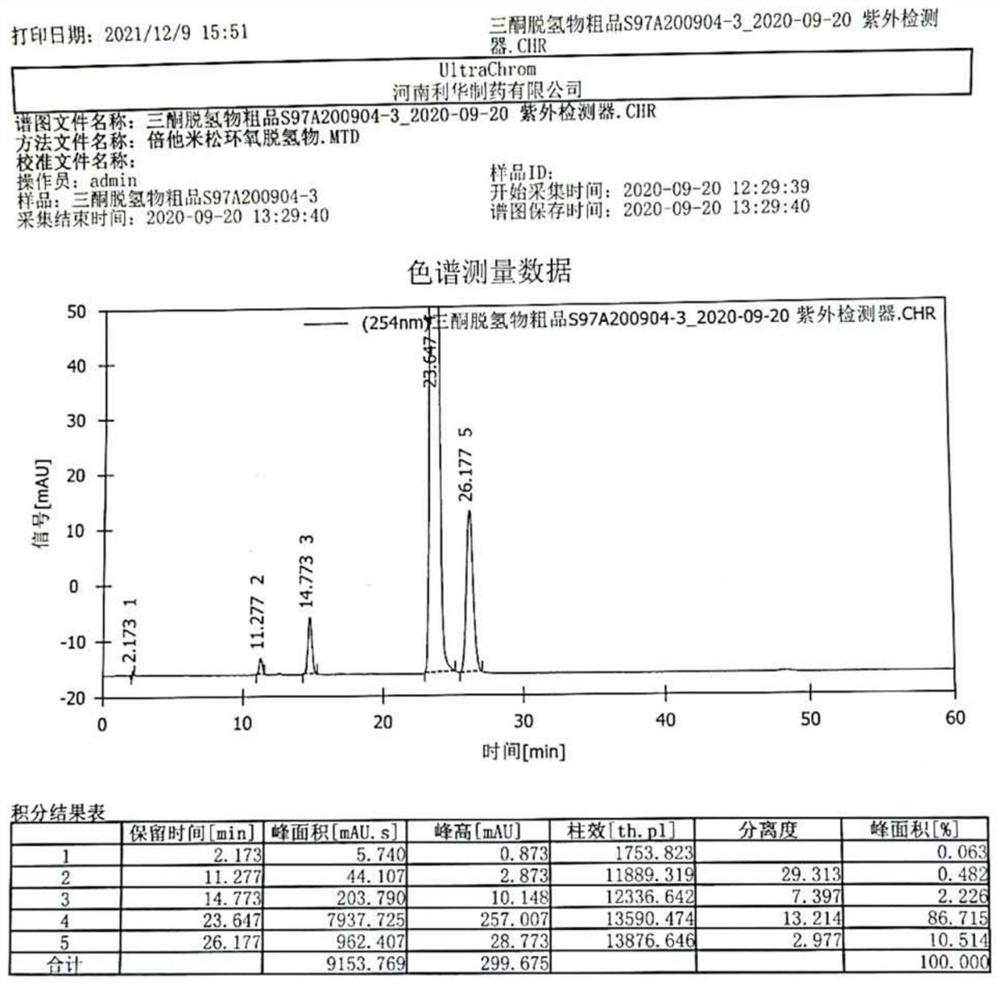

Embodiment 3

[0059] S31, mixing the triketone and water with a mass ratio of 1:2, then stirring and beating at a stirring speed of 130r / min, the stirring and beating time is 30min, to obtain a slurry;

[0060] Add Tween 80 dispersant to the slurry, and the mass ratio of slurry to dispersant is 1:0.03. After stirring and mixing, heat up to about 121°C for sterilization for 25 minutes, and then cool down to room temperature to obtain a triketone slurry;

[0061] S32, first add 4% methanol to the fermentation culture liquid, and after 2 hours, put the processed slurry into the fermentation culture liquid of Arthrobacter simplex twice, and the total concentration of the slurry is 4% of the fermentation culture liquid, wherein , the first feeding amount accounted for 30% of the total feeding amount, after 25h, the remaining slurry was added, and cultivated for 40h under the conditions of 34°C and 150r / min to obtain triketone dehydrogenate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com