All-regenerative Brayton cycle and absorption refrigeration integrated power and cooling combined supply system

An absorption refrigeration and electric cooling technology, which is applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve problems such as heat loss and cooling water consumption, reduce investment costs, reduce heat exchange losses, and increase power generation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

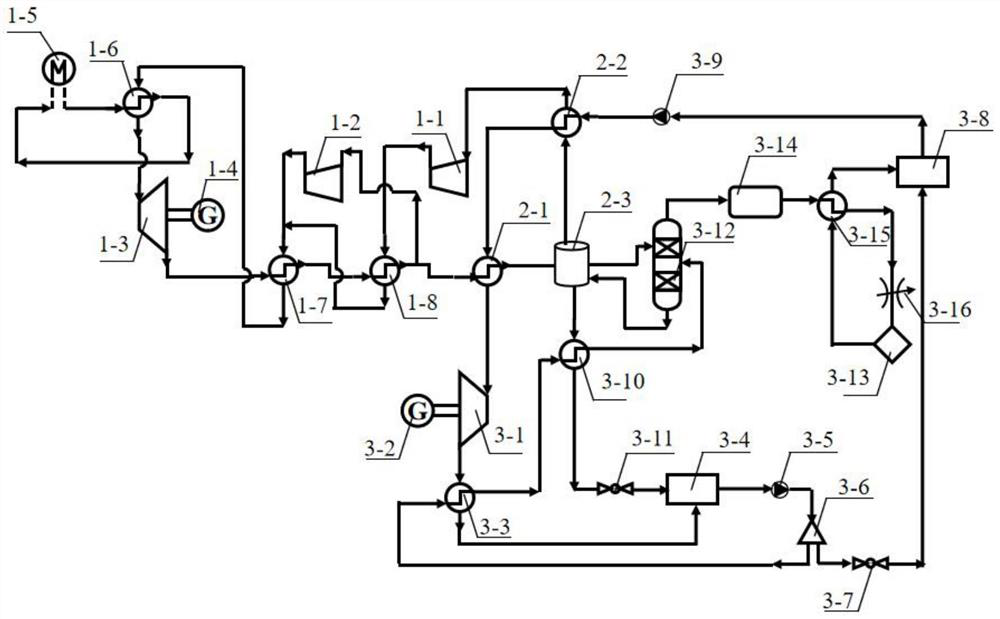

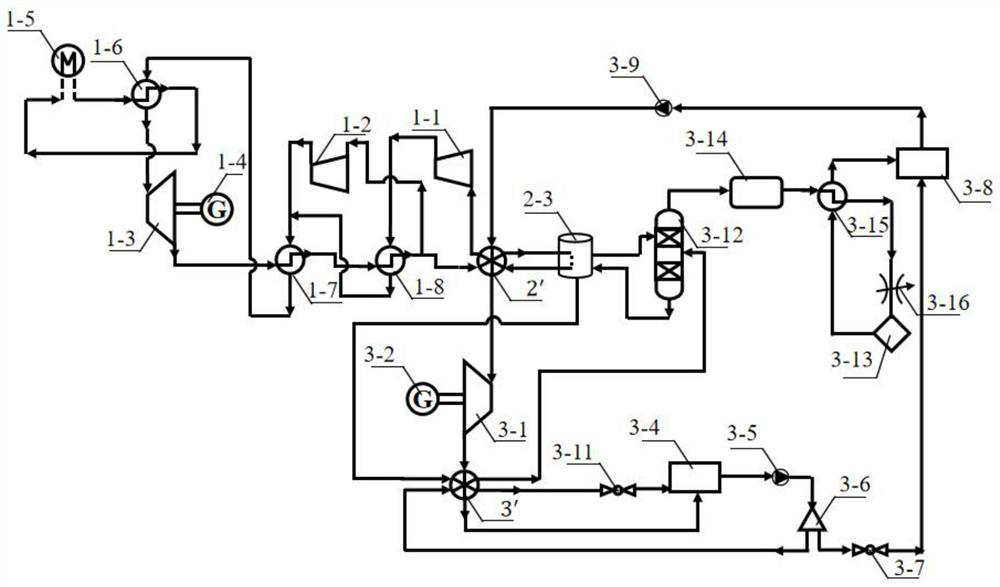

[0064] The system in this embodiment is as figure 1 As shown, the combined power-cooling system integrated with total recuperation Brayton cycle and absorption refrigeration provided by the present invention will be described below in conjunction with the specific working condition data shown in Table 1.

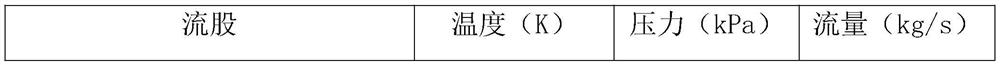

[0065] Table 1 Main equipment import and export stream status table

[0066]

[0067]

[0068]

[0069]

[0070] In this embodiment, it can be seen from Table 1 that the temperature of supercritical carbon dioxide at the hot side outlet of low temperature regenerator 1-8 is 442.35K, and the pressure is 7550kPa, while the supercritical carbon dioxide of main compressor 1-1 is at an inlet pressure of 308.15 K, the pressure is 7400kPa, in the conventional supercritical carbon dioxide Brayton cycle, the heat carried by this part of the stream is directly consumed by the cooling water at ambient temperature in the precooler to flow through the supercritical carbon dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com