Preparation method of high-speed photoelectric detector chip

A photodetector and chip technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as excessive window size, decreased responsivity, and reduced photosensitive surface, achieving high response rate and reducing capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

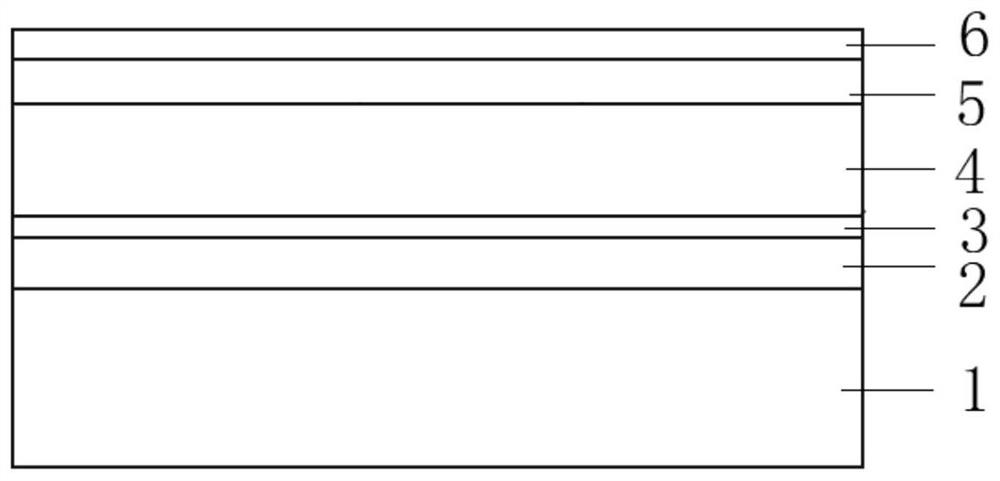

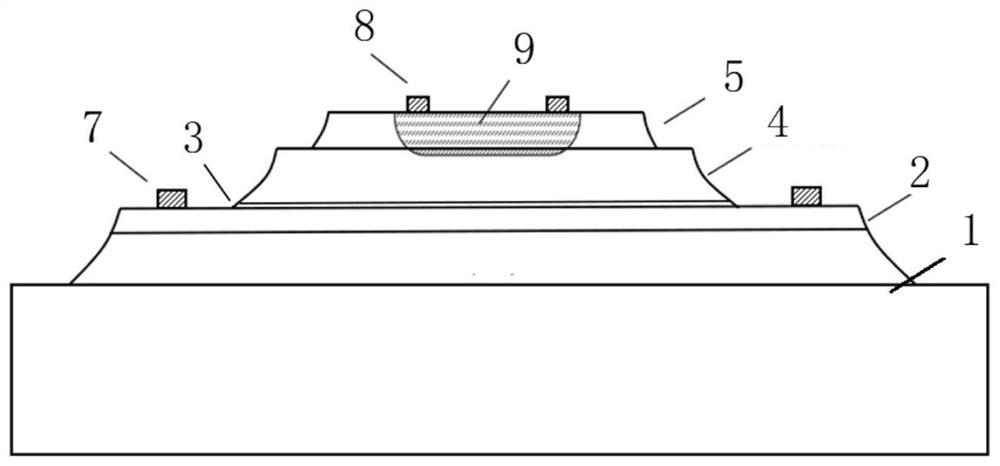

[0041] see figure 1 with figure 2 , a high-speed photodetector chip provided by an embodiment of the present invention includes a substrate 1 and an epitaxial layer grown on the substrate 1, wherein the epitaxial layer includes an N-type InGaAs contact layer 2 from bottom to top, an InP etch stop layer 3. InGaAs absorption layer 4, InGaAsP transition layer 5, and InGaAs contact layer 6.

[0042] Further, a high-speed photodetector chip provided by an embodiment of the present invention further includes an N electrode 7 disposed on the N-type InGaAs contact layer 2 , and a P electrode 8 disposed on the InGaAs contact layer 6 . In the present invention, the N electrode is arranged on the N-type contact layer made of InGaAs material. Since the forbidden band width of the InGaAs material is 1.43eV~0.35eV, the N-type InGaAs contact layer can be directly connected with the Ti-Pt-Au metal forming the N electrode. layer forms a good metal-semiconductor contact. In the chip prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com