Positive electrode material for self-supporting film type lithium secondary battery, method for preparing same, and lithium secondary battery comprising same

A technology for lithium secondary batteries and positive electrode materials, applied in the direction of lithium batteries, battery electrodes, positive electrodes, etc., can solve the problems of reduced positive electrode load, increased time and cost, and reduced energy density, achieving high load capacity, cost and The effect of time improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Preparation method of cathode material for lithium secondary battery

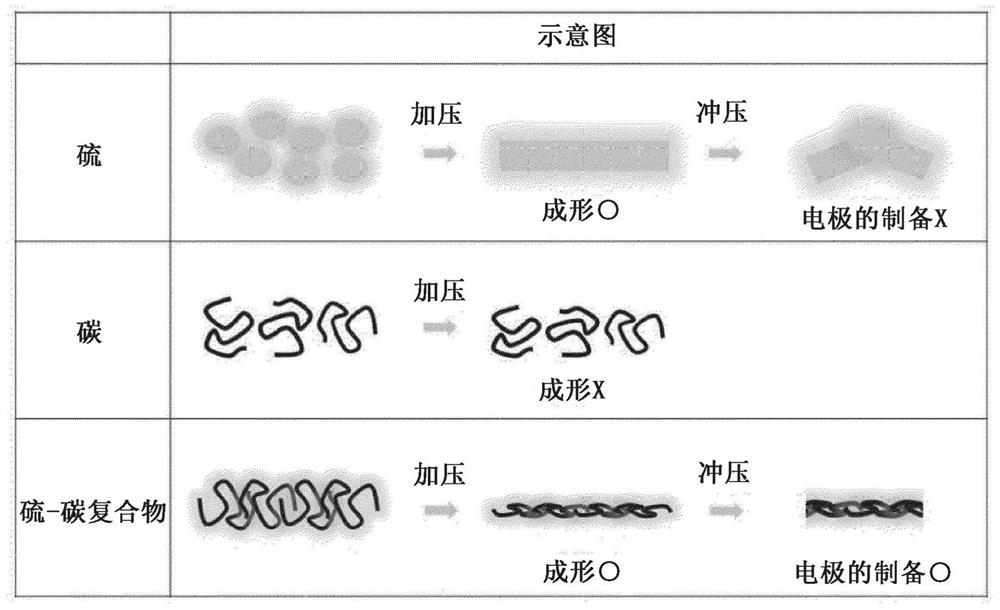

[0058] figure 1 is a schematic diagram showing changes in physical properties and formability when pressing sulfur, carbon, and sulfur-carbon composites that can be used as positive electrode materials for lithium secondary batteries.

[0059] Sulfur can be shaped because its surface melts under pressure and exhibits a property of agglomerating with surrounding sulfur, but since sulfur is not flexible, a positive electrode material (cathode) in the form of a self-standing film cannot be prepared from sulfur alone.

[0060] Since carbon is flexible, but lacks cohesive strength, it cannot be individually shaped when pressed, and thus a positive electrode material (cathode) in the form of a self-standing film cannot be prepared.

[0061] Sulfur-carbon composites are composites of sulfur and porous carbon materials. In the case of a sulfur-carbon composite, since sulfur also exists on the outer surface...

preparation example 1

[0096] Preparation Example 1: Preparation of Sulfur-Carbon Composite

[0097] Sulfur (S) and carbon nanotubes (CNT) were uniformly mixed in a solid state at a weight ratio of 65:35, and then ball milled at 100 rpm for 1 hour to prepare a mixture.

[0098] The mixture was heat-treated at 155° C. for 35 minutes to load sulfur into the pores of the CNT and coat the surface thereof to prepare a sulfur-carbon composite (S-CNT). In this case, use a 350m 2 / g specific surface area of CNT.

Embodiment 1

[0100] (1) Preparation of self-supporting film cathode material

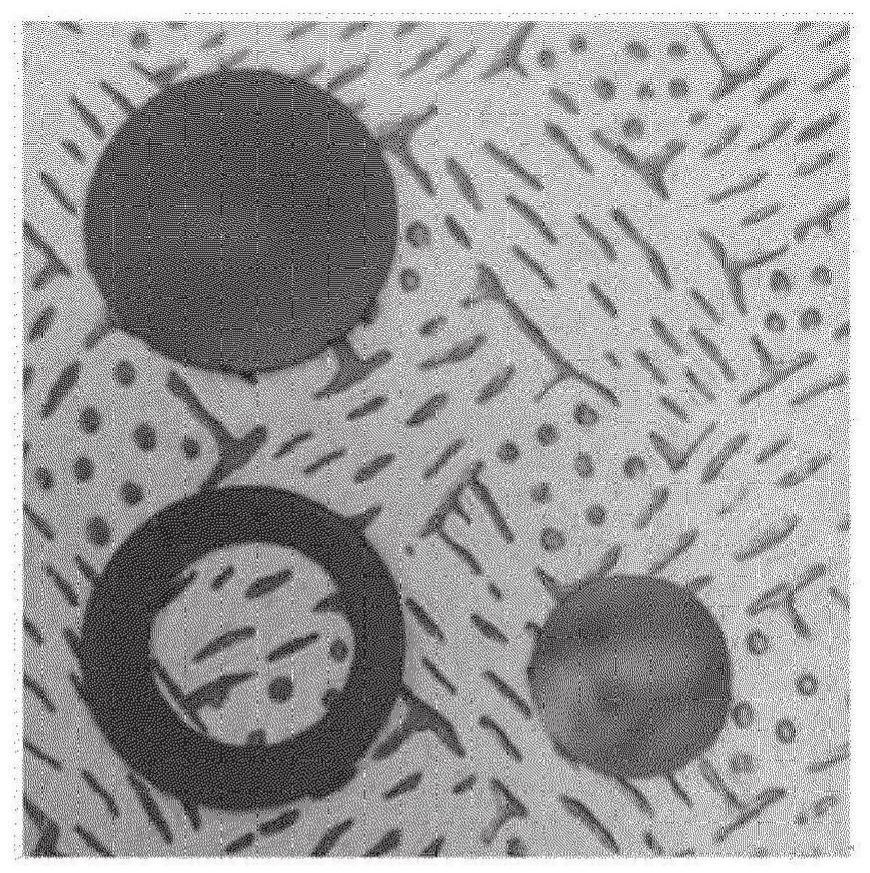

[0101] Fill the mold with the sulfur-carbon composite (S-CNT) of Preparation Example 1, and use a hydraulic press to pressurize at a pressure of 1 MPa to form a carbon-containing sulfur melt, thereby preparing a self-supporting film type positive electrode material, such as figure 2 shown in .

[0102] (2) Manufacture of lithium-sulfur secondary batteries

[0103] The prepared self-supporting film type positive electrode material was prepared as a positive electrode, and lithium metal having a thickness of 150 μm was prepared as a negative electrode.

[0104] Lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) at a concentration of 1M and lithium nitrate (LiNO at a concentration of 0.1M 3 ) in an organic solvent formed by mixing tetraethylene glycol dimethyl ether (TEGDME) / dioxolane (DOL) / dimethoxyethane (DME) in a volume ratio of 1:1:1 to Prepare electrolyte.

[0105] A porous polyethylene separator with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com