High-bioavailability turmeric composition and preparation method thereof

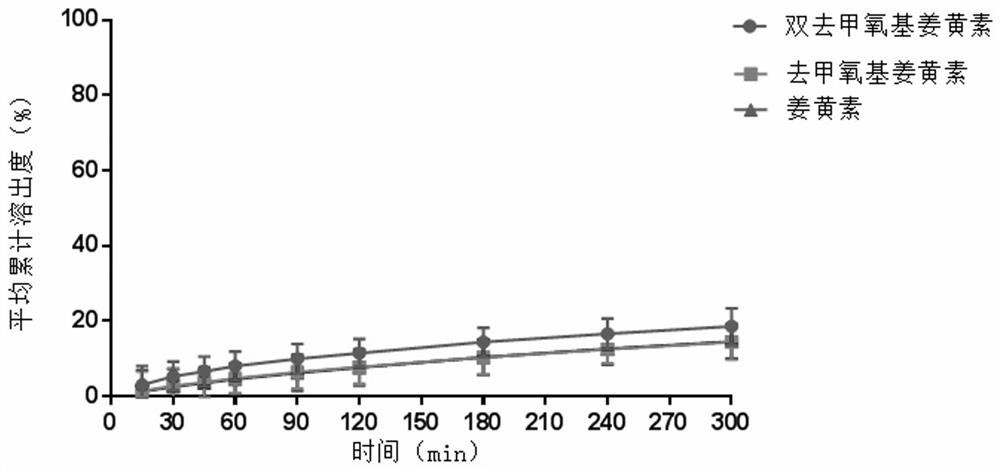

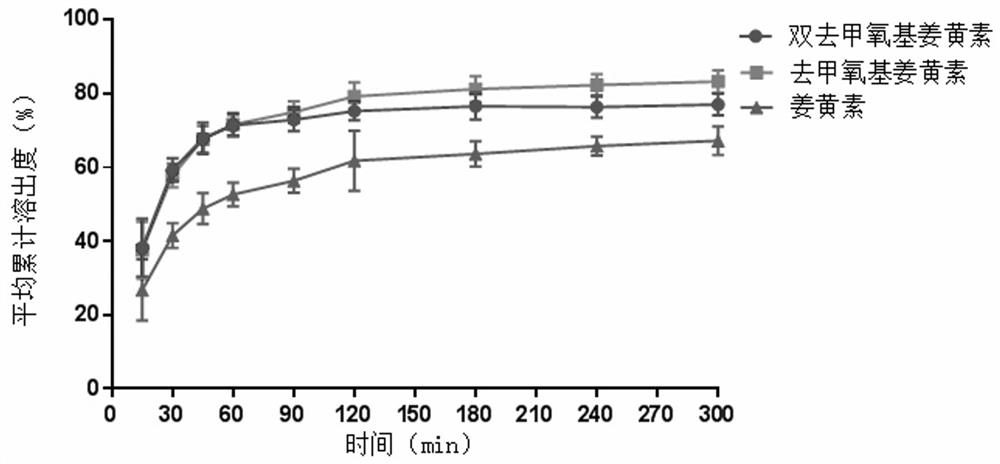

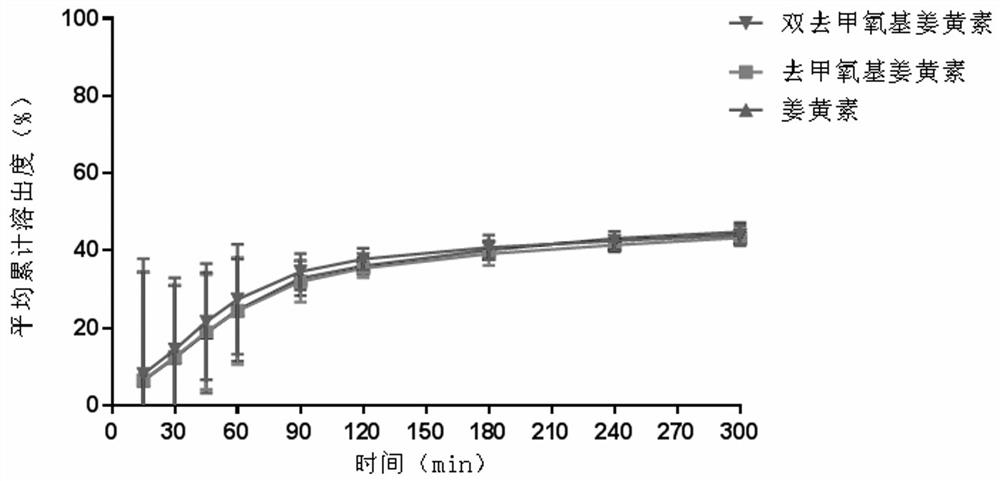

A technology of availability and composition, which is applied in the field of high bioavailability turmeric composition and its preparation, can solve the core problems of curcuminoid components dissolution and unsatisfactory bioavailability, low bioavailability of curcuminoid components and Technical difficulties and other issues, to achieve the effect of good solubility and stability, simple production equipment requirements, and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Take 1000kg of turmeric medicinal material and put it into a pulverizer for coarse crushing, put it in a multi-functional extraction tank, add 70% ethanol with 8 times the volume of the medicinal material, heat and reflux for extraction for 2.0 hours, filter the extract, and heat the dregs with 6 times the volume of 70% ethanol to reflux Extract for 1.0 hour, filter the extract, and set aside the filtrate; take the extract and concentrate it in a concentrator under reduced pressure. Heat preservation and crystallization to obtain effective ingredients of curcuminoids. Take 25 parts by weight of turmeric extract and dissolve it with an appropriate amount of ethanol solution, stir and dissolve evenly to obtain a solution of turmeric extract, and set aside; another 16 parts by weight of hydroxypropyl methylcellulose and 5 parts by weight of phospholipids are placed in a batching tank, and then added Water equivalent to 15 times the amount of hydroxypropyl methylcellulose a...

Embodiment 2

[0066] Take 20 parts by weight of turmeric extract and dissolve it with an appropriate amount of ethanol solution, stir and dissolve evenly to obtain a solution of turmeric extract, and set aside; another 15 parts by weight of hydroxypropyl methylcellulose and 5 parts by weight of phospholipids are placed in the batching tank, and then add Water equivalent to 15 times the amount of hydroxypropyl methylcellulose and stirred to dissolve evenly, then use a homogenizer, homogenization temperature: 50 ° C, pressure: 75MPa, to obtain a uniform and stable hydroxypropyl methylcellulose-phospholipid Sol, for standby; take the above turmeric extract solution and hydroxypropyl methylcellulose-phospholipid sol and mix them in the preparation tank, use a homogenizer for homogenization, homogenization temperature: 50°C, pressure: 35MPa; then add 59.5 Parts by weight of maltodextrin and 0.5 parts by weight of citric acid, mixed evenly; take the material liquid and dry it in a spray dryer, the...

Embodiment 3

[0068] Take 20 parts by weight of turmeric extract and dissolve it with an appropriate amount of ethanol solution, stir and dissolve evenly to obtain a solution of turmeric extract, and set aside; another 10 parts by weight of hydroxypropyl methylcellulose and 10 parts by weight of phospholipids are placed in a batching tank, and then add Water equivalent to 15 times the amount of hydroxypropyl methylcellulose and stirred to dissolve evenly, then use a homogenizer, homogenization temperature: 60 ° C, pressure: 65MPa, to obtain uniform and stable hydroxypropyl methylcellulose -- Phospholipid sol, spare; take the above turmeric extract solution and hydroxypropyl methylcellulose-phospholipid sol and mix them in the preparation tank, use a homogenizer for homogenization, homogenization temperature: 60°C, pressure: 25MPa; then add 58.5 parts by weight of maltodextrin and 1.5 parts by weight of citric acid are mixed evenly; the feed liquid is dried in a spray dryer, the inlet air tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com