High-solid anaerobic treatment method for kitchen waste

A technology for kitchen waste and anaerobic treatment is applied in the field of kitchen waste treatment and high-solid anaerobic digestion and treatment of kitchen waste to achieve the effects of increasing solid content, low operating energy consumption and overcoming large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

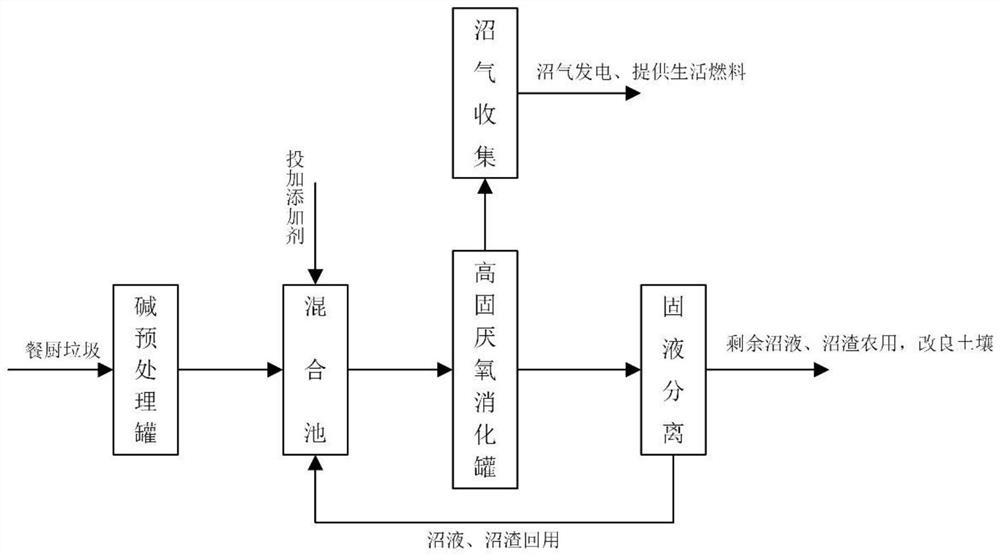

Image

Examples

Embodiment 1

[0024] The food waste with a solid content of 22.5% is pulverized and directly enters the pretreatment tank for dry alkali pretreatment. The pretreatment material is 3% CaO, the temperature is 25°C, and the solid residence time is 1 day; The food waste after alkali pretreatment is diluted to a solid content rate of 12%, and then anaerobic digestion is performed. The reaction temperature is 35°C, the solid residence time is 35 days, and the methane yield is 140.1CH 4 / g-VSadd, the methane yield increased by 232.8% compared with the untreated and no bentonite, and the stagnation period of gas production was 4 days, which was shortened by 9 days.

Embodiment 2

[0026] The food waste with a solid content of 25.3% is pulverized and directly enters the pretreatment tank for dry alkali pretreatment. The pretreatment material is 4% CaO, the temperature is 25°C, and the solid residence time is 1 day; it is diluted to contain After the solid rate was 12%, bentonite was added at 0.6g / g-VS for anaerobic digestion, the reaction temperature was 37°C, the solid residence time was 40 days, and the methane yield was 153.0mL CH 4 / g-VSadd, the methane yield increased by 261.7%, and the COD removal rate was 82.2%, an increase of 7.2%.

Embodiment 3

[0028] The food waste with a solid content of 25.3% is pulverized and directly enters the pretreatment tank for dry alkali pretreatment. The pretreatment material is 2% CaO, the temperature is 25°C, and the solid residence time is 1 day. After the solid rate was 12%, bentonite was added at 0.6g / g-VS for anaerobic digestion, the reaction temperature was 37°C, the solid residence time was 40 days, and the methane yield was 178.9mL CH 4 / g-VSadd, the methane yield increased by 322.9%, and the COD removal rate was 80.0%, an increase of 5.0% compared with the untreated and no bentonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com