Preparation method of aliphatic diol

An aliphatic diol and cathode technology, which is applied in electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of high yield of aliphatic diol, inconvenient large-scale production, large discharge of three wastes, etc., and meet the equipment requirements Not high, reduce the production of metal ions, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

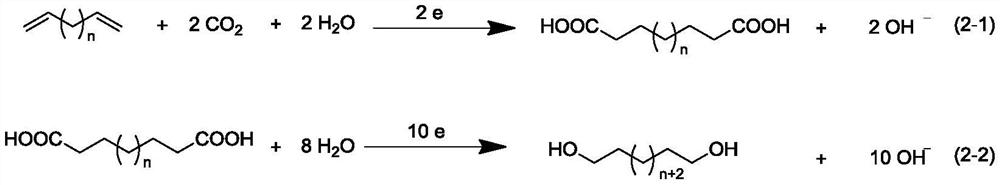

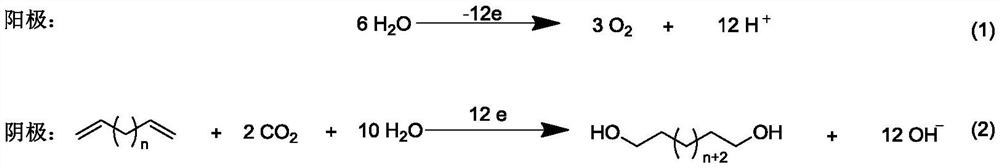

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Cathode preparation method:

[0051] Polish the 2mm thick titanium substrate with 600, 800, and 1500 mesh sandpaper for 5 minutes in sequence, then put it into the polishing solution containing 15wt% HF and 25wt% nitric acid for 20 seconds, take it out, rinse it with deionized water for two minutes, and then put it Sonicate in ethanol for 5 minutes, take it out and dry it. Use the electrode as the anode and the graphite sheet as the cathode, and polarize for 30 minutes under constant potential conditions in 100ml of polarizing solution containing 0.5wt% HF and 0.15wt% TiCl 4 Ethylene glycol solution. Wherein, cathode electrode area: anode electrode area=4, above operation makes TiO 2 array of nanotubes.

[0052] After taking out the above electrode, put it in the electroplating solution containing 0.3M nickel sulfate, use the electrode as the cathode, and the platinum sheet as the anode, conduct constant current electroplating at room temperature for 30 minutes, and ...

Embodiment 2

[0056] Polish the 2mm thick zinc substrate with 600, 800, and 1000 mesh sandpaper for 5 minutes in sequence, then put it into the polishing solution containing 15wt% HF and 25wt% nitric acid for 10 seconds, take it out, rinse it with deionized water for two minutes, and then put it Sonicate in ethanol for 5 minutes, take it out and dry it. Use the electrode as the anode and the graphite sheet as the cathode, and polarize for 60 minutes under constant potential conditions in 100ml of polarizing solution containing 0.5wt% HF, 0.25wt% ZnCl 2 Ethanol solution, wherein, cathode electrode area: anode electrode area=4, above operation makes ZnO nanotube array.

[0057] After taking out the above electrode, put it in the electroplating solution containing 0.6M cobalt sulfate, use the electrode as the cathode, and the platinum sheet as the anode, conduct constant current electroplating at room temperature for 40 minutes, and the current size is 0.5A. After taking out the electrode, was...

Embodiment 3

[0060] Cathode preparation method:

[0061] Polish the 2mm thick titanium substrate with 600, 800, and 1500 mesh sandpaper for 5 minutes in sequence, then put it into the polishing solution containing 15wt% HF and 25wt% nitric acid for 20 seconds, take it out, rinse it with deionized water for two minutes, and then put it Sonicate in ethanol for 5 minutes, take it out and dry it. The electrode is used as an anode and polarized for 40 minutes under constant potential conditions in 100ml polarizing solution, which contains 0.5wt% HF, 0.15wt% TiCl 4 Ethylene glycol solution, the corresponding cathode is graphite sheet, wherein, cathode electrode area: anode electrode area=4, above operation makes TiO 2 array of nanotubes.

[0062] After taking out the above electrode, put it in the electroplating solution containing 0.5M copper sulfate, use the electrode as the cathode, and the platinum sheet as the anode, conduct constant current electroplating at room temperature for 30 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com