Processing method of bagged silage with one-way exhaust valve

A one-way exhaust valve, silage technology, applied in the preservation method of animal feed raw materials, valve device, animal feed and other directions, can solve the problems of high explosion rate of packaging bags, corruption, mildew of silage, etc., to reduce Effects of moisture retention and delamination, improved quality and reduced breakage rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

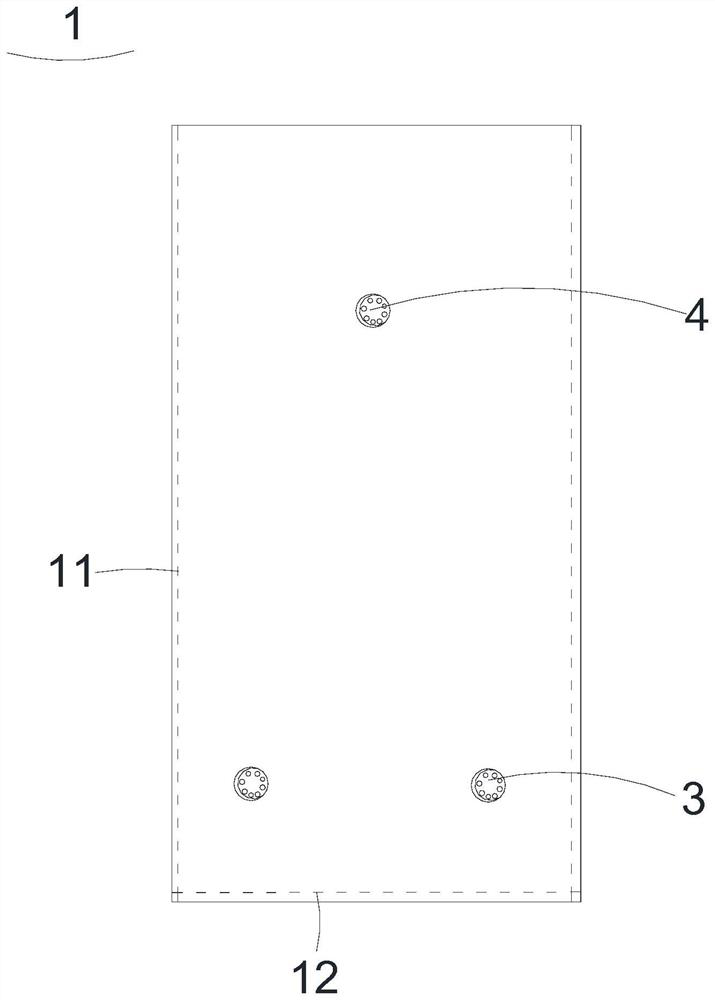

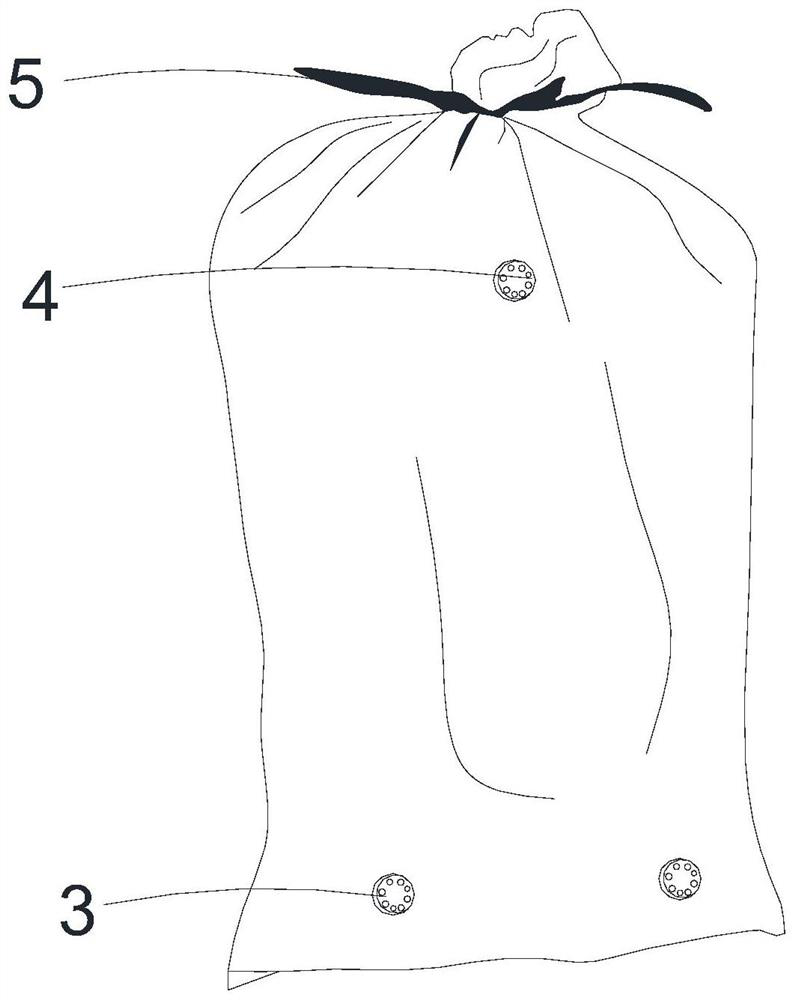

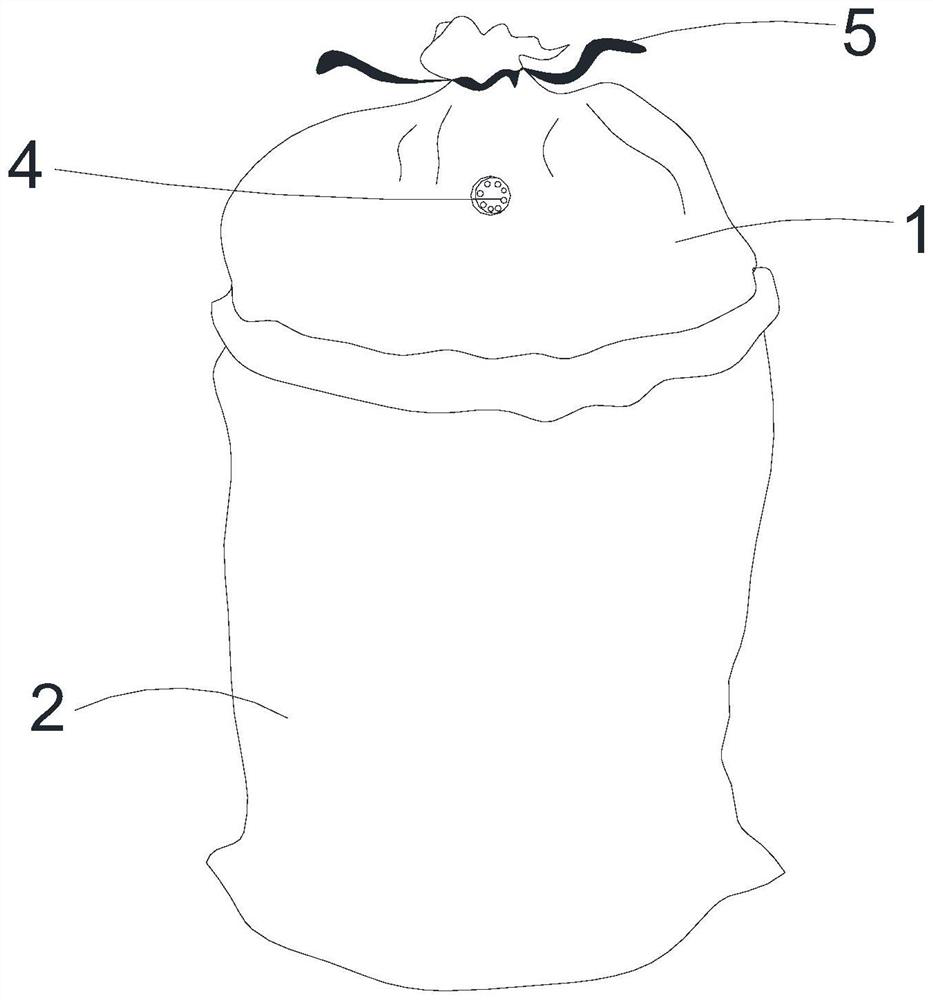

[0035] Such as Figure 1 to Figure 3 As shown, the first embodiment of the present invention provides a method for processing bagged silage with a one-way exhaust valve, following steps:

[0036] Preparation of raw materials: process the raw materials into scraps, specifically, use the grass cutter or kneading machine in the prior art to process the fiber-containing straws, specifically use the model 9Z-30 of Luoyang Sida Agricultural Machinery Co., Ltd. The raw material was processed by a hay cutter; the length of the scrap was 1.5 cm.

[0037] Cutting inner bag material: take recycled plastic and cut it into two rectangular plastic pieces, among which, the recycled plastic is polyethylene, the thickness of the recycled plastic is 0.05mm, the color of the recycled plastic is blue, the length of the rectangular plastic piece is 135cm, and the width is 72cm .

[0038] Hot-melt into bags: heat-melt the two long sides and one short side of two rectangular plastic sheets to form...

Embodiment 2

[0045] Such as Figure 1 to Figure 3 As shown, the second embodiment of the present invention provides a method for processing bagged silage with a one-way exhaust valve, following steps:

[0046] Preparation of raw materials: process the raw materials into scraps, specifically, use the grass cutter or kneading machine in the prior art to process the fiber-containing straws, specifically use the model 9Z-30 of Luoyang Sida Agricultural Machinery Co., Ltd. The raw material was processed by a hay cutter; the length of the scrap was 1 cm.

[0047] Cutting the inner bag raw material: take the recycled plastic and cut it into two rectangular plastic sheets, among which, the recycled plastic is polyethylene, the thickness of the recycled plastic is 0.05mm, the color of the recycled plastic is blue, the length of the rectangular plastic sheet is 125cm, and the width is 62cm .

[0048] Hot-melt into bags: heat-melt the two long sides and one short side of two rectangular plastic she...

Embodiment 3

[0055] Such as Figure 1 to Figure 3 As shown, the third best embodiment of the present invention provides a method for processing bagged silage with a one-way exhaust valve, following steps:

[0056] Preparation of raw materials: process the raw materials into scraps, specifically, use the grass cutter or kneading machine in the prior art to process the fiber-containing straws, specifically use the model 9Z-30 of Luoyang Sida Agricultural Machinery Co., Ltd. The raw material was processed by a hay cutter; the length of the scrap was 2 cm.

[0057] Cutting the inner bag raw material: take the recycled plastic and cut it into two rectangular plastic pieces, among which, the recycled plastic is polyethylene, the thickness of the recycled plastic is 0.05mm, the color of the recycled plastic is blue, the length of the rectangular plastic piece is 145cm, and the width is 82cm .

[0058] Hot-melt into bags: heat-melt the two long sides and one short side of two rectangular plastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com