Degradable artificial dura mater with double-layer structure and preparation method of degradable artificial dura mater

A technology of artificial dura mater and double-layer structure, applied in prosthetics, medical science, etc., can solve problems such as lack, and achieve the effects of controllable production process, single component, and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

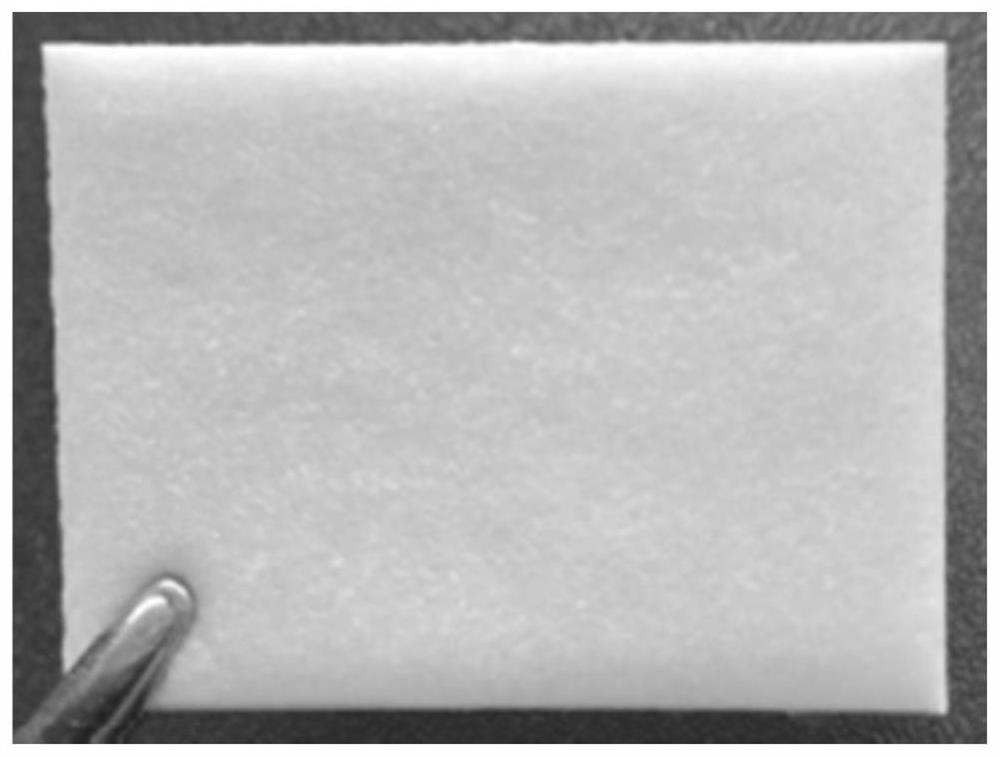

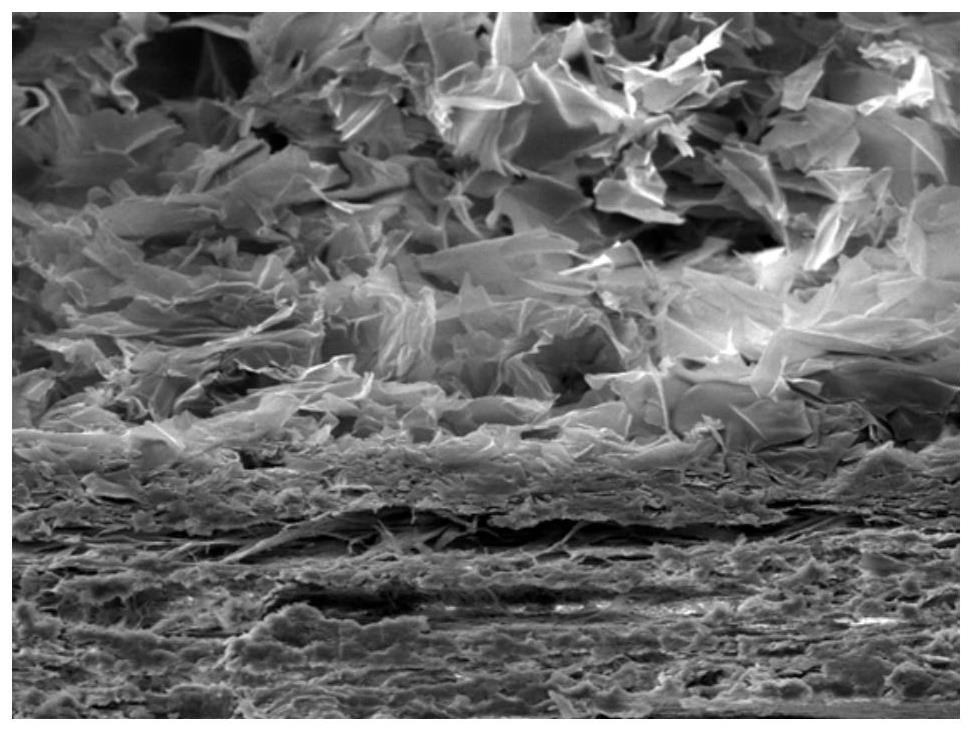

Image

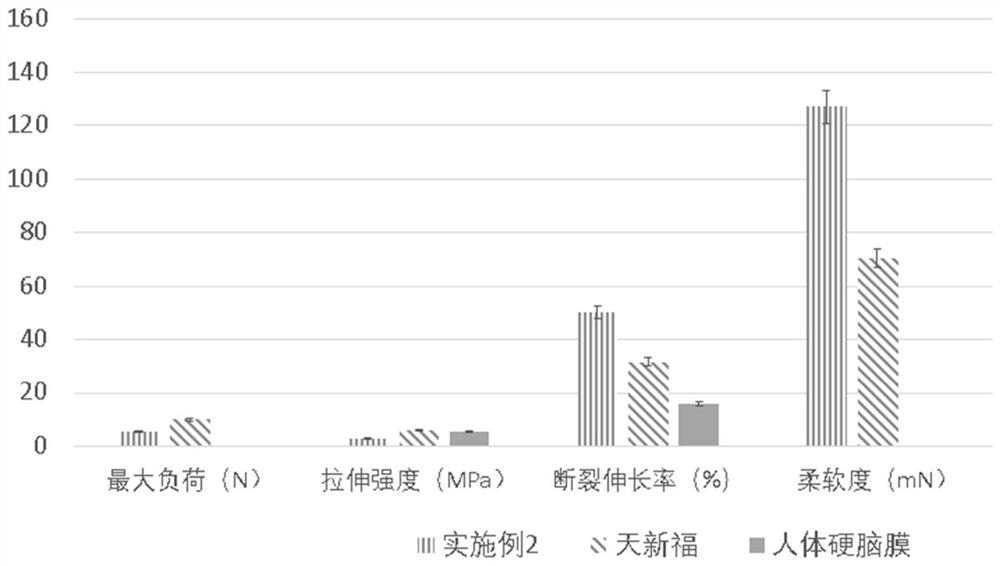

Examples

Embodiment 1

[0043] (1) Preparation of the scaffold layer: prepare a recombinant human-like collagen type I solution with a mass concentration of 30% in purified water, and after it dissolves, slowly add a cross-linking agent BDDE with a mass concentration of 0.2% in a stirring state to make the cross-linked The good gel was left to stand for 1 hour, and then put into a dialysis bag; put the dialysis bag in a buffer solution of pH 7.4, add a stirring device to continue stirring, change the liquid every 2 hours, and stop when there is no free BDDE in the dialysate Stir. Pour out the solution in the dialysis bag and stir evenly to obtain cross-linked collagen.

[0044] Then use purified water to prepare a recombinant type I humanoid collagen solution with a mass concentration of 20%. The recombinant type I human-like collagen solution, the mass ratio of the recombinant type I human-like collagen in the two is 3:2 for mixing), then spray horizontally or coat on a flat plate with a thickness ...

Embodiment 2

[0048] (1) Preparation of the scaffold layer: prepare a recombinant human-like collagen type I solution with a mass concentration of 20% in purified water, and after it dissolves, slowly add a cross-linking agent BDDE with a mass concentration of 0.1% under stirring to dissolve the cross-linked collagen The good gel was left to stand for 1 hour, and then put into a dialysis bag; put the dialysis bag in a buffer solution of pH 7.4, add a stirring device to continue stirring, change the liquid every 2 hours, and stop when there is no free BDDE in the dialysate Stir. Pour out the solution in the dialysis bag and stir evenly to obtain cross-linked collagen.

[0049] Then use purified water to prepare a recombinant human-like collagen type I solution with a mass concentration of 30%. After it dissolves, mix it with cross-linked collagen, and then spray it horizontally or spread it on a flat plate with a thickness of 1.0-1.5mm, and let it dry at room temperature for 2 After ~4h, wh...

Embodiment 3

[0056] (1) Preparation of the scaffold layer: prepare a recombinant human-like collagen type I solution with a mass concentration of 40% in purified water. The good gel was left to stand for 1 hour, and then put into a dialysis bag; put the dialysis bag in a buffer solution of pH 7.4, add a stirring device to continue stirring, change the liquid every 2 hours, and stop when there is no free BDDE in the dialysate Stir. Pour out the solution in the dialysis bag and stir evenly to obtain cross-linked collagen.

[0057] Then use purified water to prepare a recombinant human-like collagen type I solution with a mass concentration of 20%. After it dissolves, mix it with cross-linked collagen, and then spray it horizontally or spread it on a flat plate with a thickness of 1-1.5mm, and let it dry at room temperature for 2 ~4h, when the thickness decreases by 0.3-0.6mm, the scaffold layer is obtained; the scaffold layer is placed in a -20°C refrigerator to freeze, and the scaffold lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com