Desulfurization system and method suitable for complex iron desulfurizer

A technology of desulfurization system and desulfurizer, applied in the field of coking, can solve problems such as poor quality of sulfur cake, accumulation of buffer tanks, high energy consumption of the system, and achieve the effect of increasing the value of by-products and realizing separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Explanation of terms: Complex iron desulfurizer desulfurization: It is a technology that uses complex iron desulfurizer to complete the removal of hydrogen sulfide in sulfur-containing gas. Become a solid sulfur product.

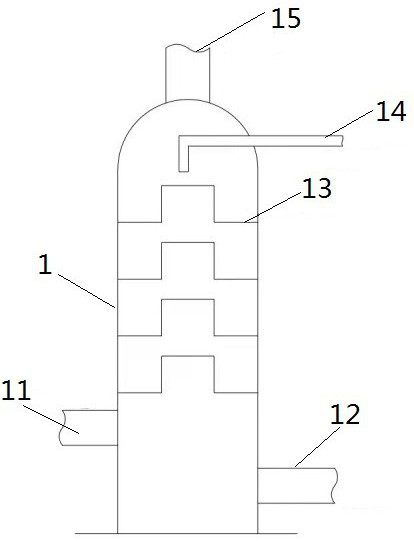

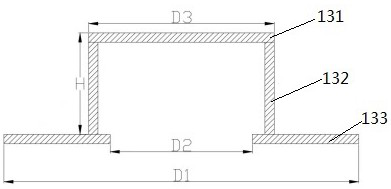

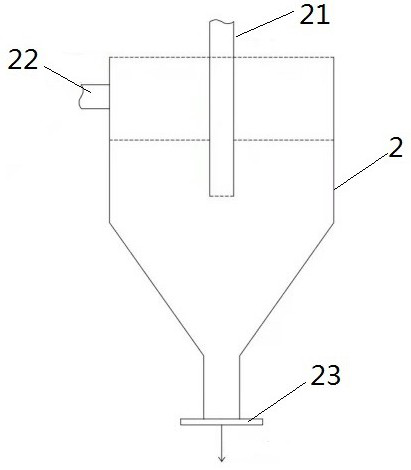

[0054] Such as Figure 1-Figure 4 As shown, the present application discloses a desulfurization system suitable for complex iron desulfurizers, including a desulfurization tower 1, the desulfurization tower 1 is communicated with a sedimentation separator, and the sedimentation separator is communicated with a low-level regenerator 3, and the low-level regeneration Device 3 is a regenerator liquid phase distributor, and the settling separator communicates with the plate frame through the suspension pump, the plate frame communicates with the low-level regenerator, and the plate frame communicates with the preprocessor. The preprocessor is communicated with the metering commercial tank, the metering commercial tank is communicated with the desulfuriza...

Embodiment 2

[0061] Such as Figure 5 and 6 As shown, the application also discloses a desulfurization method applicable to a complex iron desulfurizer, comprising the following steps:

[0062] S1. The gas containing hydrogen sulfide enters the middle of the desulfurization tower and contacts with the top-down desulfurization lean liquid from the top of the desulfurization tower. After the hydrogen sulfide gas is removed, the gas is discharged from the top of the desulfurization tower and enters other processes;

[0063] S2. The desulfurization-rich liquid after absorbing hydrogen sulfide flows into the sedimentation separator through the liquid seal section at the lower part of the desulfurization tower, and the desulfurization-rich liquid from which sulfur particles are separated by the sedimentation separator flows into the low-level regenerator, and the high-solid liquid separated by the sedimentation separator The specific suspension is pressurized by the suspension pump and sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com