Method for manufacturing chemical mechanical polishing dresser

A technology of chemical machinery and dresser, which is applied in the direction of manufacturing tools, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of inconsistency in the size, shape, orientation and exposed height of diamond abrasives, difficulty in processing three-dimensional microstructures, The problem of weak diamond holding power can be achieved to improve the trimming quality and efficiency, the effect of processing heat is small, and the scanning speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

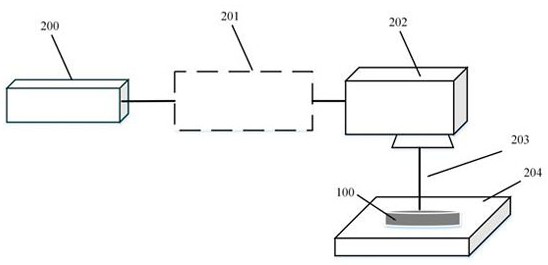

[0033] A method for manufacturing a chemical mechanical polishing trimmer, the processing system platform includes an ultraviolet picosecond laser 200, a laser optical path 201, a three-dimensional scanning galvanometer 202, a three-axis numerical control platform 204, and a laser beam 203 is output from the ultraviolet picosecond laser 200, Through the laser optical path 201, it is injected into the three-dimensional scanning vibrating mirror 202, and the three-dimensional scanning vibrating mirror 202 controls the laser to quickly scan and process the ceramic substrate on the three-axis numerical control platform 204 in the three-dimensional direction to obtain a ceramic substrate with a pyramid structure on the surface, and then A diamond film with a uniform thickness is deposited on the surface of the ceramic substrate by hot wire chemical vapor deposition, that is, a chemical mechanical polishing trimmer is manufactured.

Embodiment 2

[0035] A method for manufacturing a chemical mechanical polishing trimmer, the specific steps are as follows:

[0036] (1) Build a processing system platform: The built laser processing system platform includes an ultraviolet picosecond laser, a laser optical path, a three-dimensional scanning galvanometer, and a three-axis numerical control platform.

[0037] (2) Clamp and fix the cleaned ceramic substrate on the three-axis CNC platform, and move the upper surface of the ceramic substrate to the plane position of the laser focus, waiting for processing.

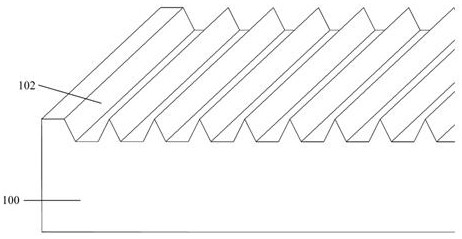

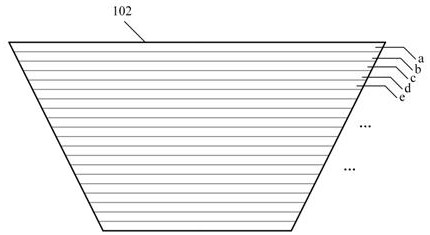

[0038] (3) The laser is controlled by the 3D scanning galvanometer to scan the ceramic substrate in step (2) along the first direction, and a number of inverted trapezoidal grooves are processed, and the tops of two adjacent inverted trapezoidal grooves meet to form apexes .

[0039] (4) After the groove processing in the first direction of the substrate in step (3), the laser is controlled by the three-dimensional scanning...

Embodiment 3

[0042] A method for manufacturing a chemical mechanical polishing trimmer, the specific steps are as follows:

[0043](1) The laser processing system platform built includes an ultraviolet picosecond laser 200, a laser optical path 201, a three-dimensional scanning galvanometer 202, and a three-axis numerical control platform 204. The three-dimensional scanning galvanometer 202 can control the laser light 203 to perform rapid scanning in the three-dimensional direction according to the designed processing path.

[0044] (2) Clamping and fixing the cleaned ceramic substrate 100 on the three-axis numerical control platform 204, and moving the upper surface of the ceramic substrate 100 to the focus position of the laser 203 of the three-dimensional scanning galvanometer, waiting for processing.

[0045] (3) The laser 203 is controlled by the three-dimensional scanning galvanometer 202 to scan the ceramic substrate 100 in step (2) along the first direction, and several inverted tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com