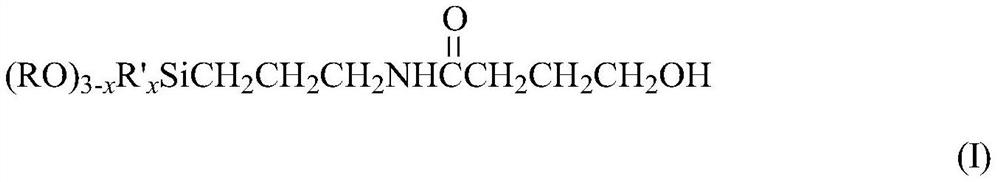

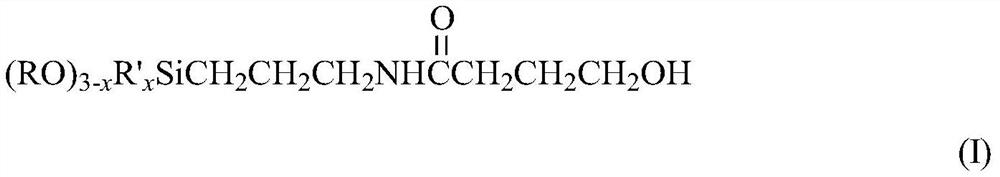

N-(4-hydroxybutyryl)-gamma-aminopropyl silane, preparation method and application of N-(4-hydroxybutyryl)-gamma-aminopropyl silane in waterproof aspect of paper-based material

A technology of aminopropylsilane and aminopropyltrimethoxysilane, which is applied in the preparation of N--γ-aminopropylsilane, the application field of preparation and waterproof treatment of paper-based materials, and can solve the problem of poor stiffness, etc. problem, to achieve the effect of waterproof stiffness and good comprehensive application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of water-based C-hydroxyl modified cationic amino silicone wax emulsion

[0032] According to the mass ratio of long-chain alkylsilane (RSi): aminohydrocarbylsilane (ASi): C-hydroxysilane (HSi) is about 70%: 10%: 20%, weigh 7.00g octadecyltrimethoxysilane in turn , 1.0g γ-aminopropyltriethoxysilane KH-550, 2.0g N-(4-hydroxybutyryl)-γ-aminopropyltriethoxysilane (HSi-1), heated and stirred, dissolved and mixed , to get a total of 10.0g of the mixture, recorded as D, placed in the insulating dropping funnel, set aside.

[0033] In a four-necked flask equipped with a thermometer, a stirrer, a reflux condenser, and an insulated dropping funnel, successively weigh 10% by D mass, about 1.00 g of octadecyltrimethylammonium chloride 1831 and fatty alcohol Cat / nonionic surfactant (1:1, wt / wt, the same below) composed of polyoxyethylene ether AEO-9 and about 10 times the amount of D in terms of mass, 99.00g of deionized water, stirred and heated, After the surfac...

Embodiment 2

[0037] (1) Preparation of water-based C-hydroxyl modified cationic amino silicone wax HAW-2 emulsion

[0038] According to the mass ratio of long-chain alkylsilane (RSi): aminohydrocarbylsilane (ASi): C-hydroxysilane (HSi) is about 90%: 1%: 9%, according to the metering ratio, weigh 9.00g dodecyl Dimethoxysilane, 0.10g γ-aminopropyltriethoxysilane KH-550, 0.9g N-(4-hydroxybutyryl)-γ-aminopropylmethyldimethoxysilane (HSi-2) , heated and stirred, dissolved and mixed to obtain a total of 10.0 g of the mixture, which was recorded as D, and placed in an insulating dropping funnel for subsequent use.

[0039] In a four-necked flask equipped with a thermometer, a stirrer, a reflux condenser and a dropping funnel, weigh 10% by D mass, about 1.00 g of cetyltrimethylammonium chloride 1631 and fatty alcohol poly The cationic / nonionic surfactant composed of oxyethylene ether O-15 and 2.567 times the amount of D-mass, about 25.67g of deionized water, stirred and heated, and the surfactant...

Embodiment 3

[0043] (1) Preparation of water-based C-hydroxyl modified cationic amino silicone wax HAW-3 emulsion

[0044] According to the mass ratio of long-chain alkylsilane (RSi): aminohydrocarbylsilane (ASi): C-hydroxysilane (HSi) is about 80%: 5%: 15%, according to the metering ratio, weigh 8.00g hexadecyl Trimethoxysilane, 0.50g N,N-dimethyl-γ-aminopropyl-γ-aminopropylmethyldimethoxysilane, 1.50g N-(4-hydroxybutyryl)-γ-aminopropyl Base trimethoxysilane (HSi-3), heated and stirred, dissolved and mixed to obtain a total of 10.0 g of the mixture, recorded as D, placed in the insulating dropping funnel, and set aside.

[0045] In a four-necked flask equipped with a thermometer, a stirrer, a reflux condenser and a dropping funnel, weigh 5% by D mass, about 0.50 g of dodecyldimethylbenzyl ammonium chloride 1227 and fat The cationic / nonionic surfactant composed of alcohol polyoxyethylene ether O-20 and 5.95 times the amount of D mass, about 59.5g of deionized water, stirred and heated, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com