Reflow soldering machining tool and machining method for motor server power device

A technology of power devices and servers, which is applied in the direction of assembling printed circuits, electrical components, and printed circuits with electrical components. It can solve the problems of low thermal conductivity, multi-space, and increased current carrying capacity of printed circuit boards to speed up processing. , The processing procedure is simple, and the effect of avoiding the bad effect of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

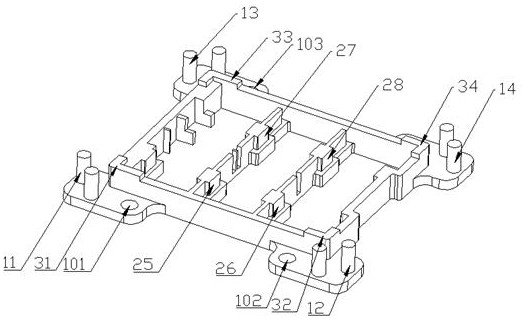

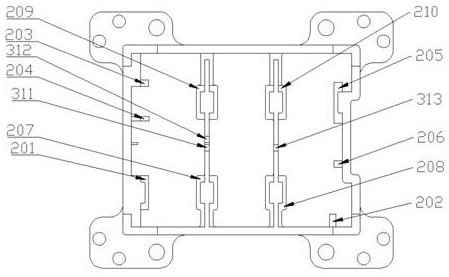

[0038]The technical solution of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings. The present invention discloses a reflow soldering processing tool for a motor servo power device and a corresponding processing method. The specific technical solution is as follows.

[0039] A reflow soldering processing tool for a motor-servo power device is characterized in that the motor-servo power device includes an insulated gate transistor module, a functional module, and a copper substrate 8 at the bottom from top to bottom.

[0040] The functional module includes a phase current output board module, a grid control board module, and a DC input board module, and the phase current output board module, the grid control board module, and the DC input board module are set On the same level, the insulated gate transistor module includes 6 identical insulated gate transistors arranged on the same level, the insulated gate tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com