Technological method and composition for improving flowability of piperacipril isethionate

A technology of piperidine isethionate and piperidine isethionate, applied in the field of medicine, can solve problems such as poor fluidity, difficulty in large-scale manufacturing, etc., and achieve the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

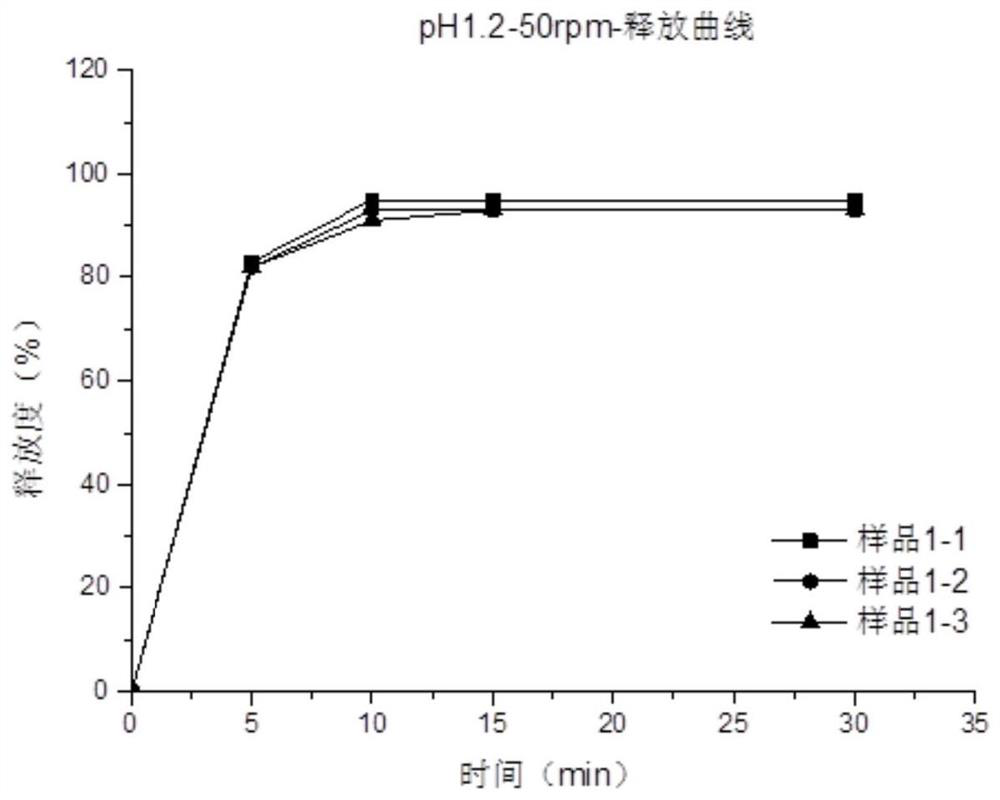

Embodiment 1

[0050] The composition of the prescription is as follows:

[0051]

[0052]

[0053] Preparation Process:

[0054] 1. Preparation of raw and auxiliary materials

[0055] Palbociclib isethionate, microcrystalline cellulose, and crospovidone are passed through a 40-mesh sieve, and lactose, colloidal silicon dioxide, and magnesium stearate are passed through a 80-mesh sieve for later use.

[0056] 2. Premix

[0057] Weigh respectively palbociclib isethionate and microcrystalline cellulose premixed according to the prescription quantity, pass through a 40-mesh sieve,

[0058] 3. mix

[0059] Add the premix, lactose, crospovidone, and colloidal silicon dioxide into a three-dimensional motion mixer and mix for 15 minutes;

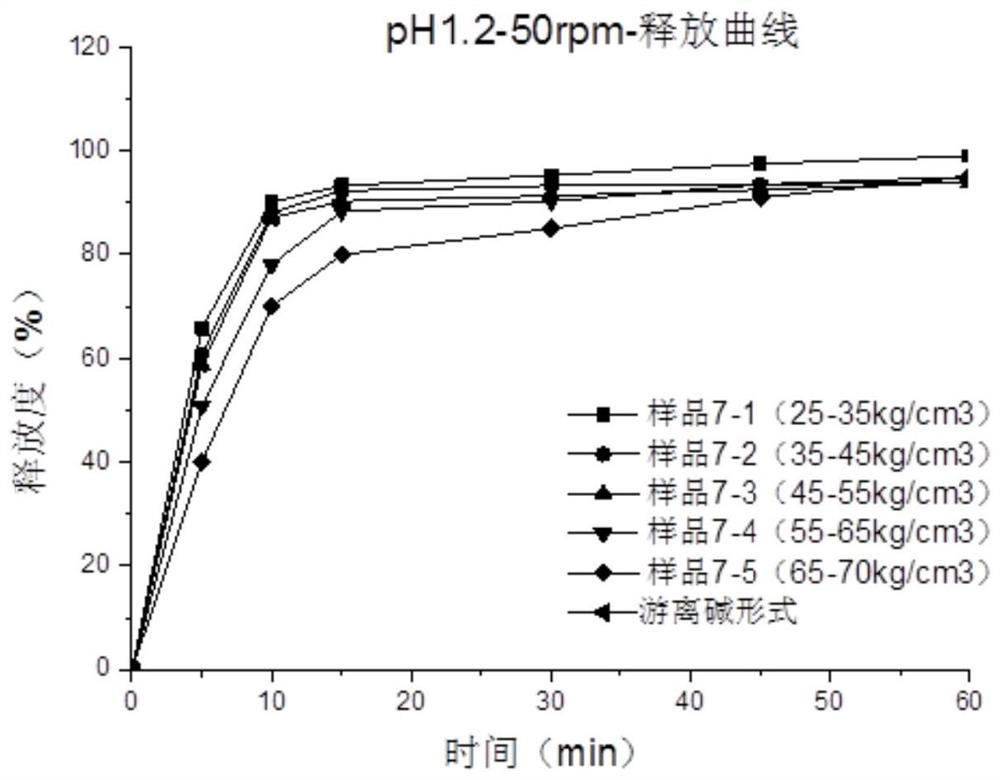

[0060] 4. Dry granulation

[0061] After setting the parameters of the dry granulator (roller pressure is set to 35-45kg / cm 3 ), the mixture obtained in step 3 is subjected to dry granulation;

[0062] 5. Total mix

[0063] Add the magnesium stearat...

Embodiment 2

[0084] The composition of the prescription is as follows:

[0085]

[0086] 1. Preparation of raw and auxiliary materials

[0087] Palbociclib isethionate, pregelatinized starch, and crospovidone are passed through a 40-mesh sieve, and lactose, colloidal silicon dioxide, and magnesium stearate are passed through a 80-mesh sieve for later use.

[0088] 2. Premix

[0089] Weigh and premix palbociclib isethionate and pregelatinized starch respectively according to the prescription quantity, pass through a 40-mesh sieve,

[0090] 3. mix

[0091] Add the premix, lactose, crospovidone, and colloidal silicon dioxide into a three-dimensional motion mixer and mix for 15 minutes;

[0092] 4. Dry granulation

[0093] After setting the parameters of the dry granulator (roller pressure is set to 35-45kg / cm 3 ), the mixture obtained in step 3 is subjected to dry granulation;

[0094] 5. Total mix

[0095] Add the magnesium stearate and the granules obtained after dry granulation i...

Embodiment 3

[0099] The composition of the prescription is as follows:

[0100]

[0101] Preparation Process:

[0102] 1. Preparation of raw and auxiliary materials

[0103]Pass through a 40-mesh sieve, palbociclib isethionate, anhydrous calcium hydrogen phosphate, and crospovidone, and pass through a 80-mesh sieve for talcum powder and sodium stearyl fumarate for later use.

[0104] 2. Premix

[0105] Weigh respectively palbociclib isethionate and anhydrous calcium hydrogen phosphate premixed according to the prescription quantity, pass through a 40-mesh sieve,

[0106] 3. mix

[0107] Add the premix, talcum powder and crospovidone into the three-dimensional motion mixer and mix for 15 minutes;

[0108] 4. Dry granulation

[0109] After setting the parameters of the dry granulator (roller pressure is set to 35-45kg / cm 3 ), the mixture obtained in step 3 is subjected to dry granulation;

[0110] 5. Total mix

[0111] Add sodium stearyl fumarate and the granules obtained by dry g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com