Process for treating sludge in domestic sewage

A technology for domestic sewage and sludge, applied in the field of processing technology, can solve problems such as performance degradation, affecting sewage sludge treatment effect, etc., and achieve the effect of strengthening adsorption treatment performance, strengthening adsorption purification treatment effect, and strengthening contact bonding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention provides a process for the treatment of sludge in domestic sewage, and the specific treatment steps are as follows:

[0031] Step 1: Pass the sewage to be treated into the coagulation tank, add coagulant, stir for 10 minutes, and then pass the sewage into the magnetic mixing tank;

[0032] Step 2: Add the composite magnetic particles into the magnetic mixing tank, and after ultrasonic treatment for 20 minutes, pass the sewage into the flocculation tank;

[0033] Step 3: Add the flocculant into the flocculation tank, stir for 10 minutes, then pass the sewage into the sedimentation tank, let it stand until the flocculation is completely settled, obtain sludge and water, and discharge the water;

[0034]Step 4: After adding the sludge to the high-speed shearing machine for strong stirring and dispersion, the composite magnetic particles are recovered through the magnetic drum separator, and the composite magnetic particles are thrown back into the magnetic mi...

Embodiment 2

[0045] Different from Example 1, the composite magnetic particles include: 3.4% catechin, 10.2% chitosan, 3.2% branched polyethyleneimine, 3.2% nano zirconium dioxide by weight percentage , 5.3% of polyaluminum chloride, 74.7% of nano ferric oxide.

Embodiment 3

[0047] Different from Examples 1-2, the composite magnetic particles include: 3.1% catechin, 9.9% chitosan, 2.9% branched polyethyleneimine, 2.9% nano Zirconium dioxide, 4.9% polyaluminum chloride, 76.3% nano ferric oxide.

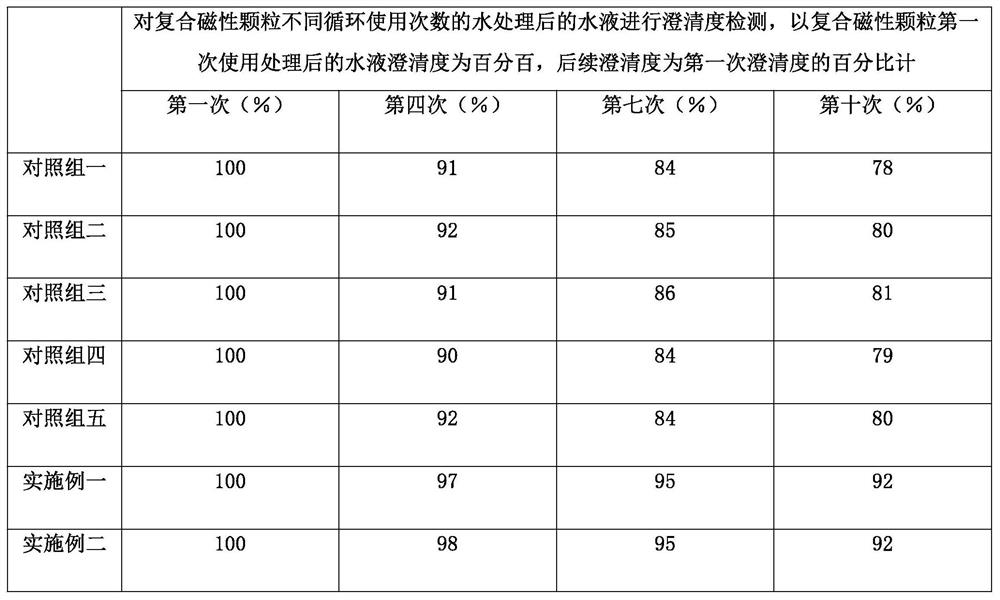

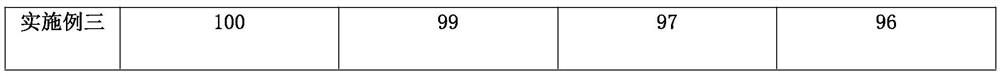

[0048] Get respectively the technology of the treatment of the sludge in the domestic sewage in the above-mentioned embodiment 1-3 and the process of the treatment of the sludge in the domestic sewage of the control group one, the process of the treatment of the sludge in the domestic sewage of the control group two, the control group The treatment process of sludge in domestic sewage of the third group, the treatment process of the sludge in the domestic sewage of the control group 4 and the treatment process of the sludge in the domestic sewage of the control group 5, the treatment process of the sludge in the domestic sewage of the control group 1 Compared with embodiment three, there is no catechin in the composite magnetic particles in the process of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com