Preparation method of alpha-cyanoacrylic acid low-whitening gel

A technology of cyanoacrylic acid and whitening glue, which is applied in the direction of adhesives, non-polymer organic compound adhesives, non-polymer adhesive additives, etc., and can solve the problem of declining market acceptance, limiting the scope of application, reducing the amount of glue used, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

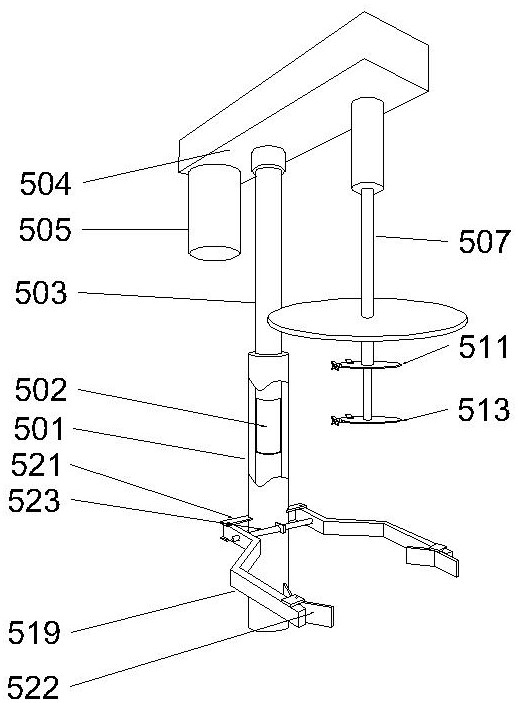

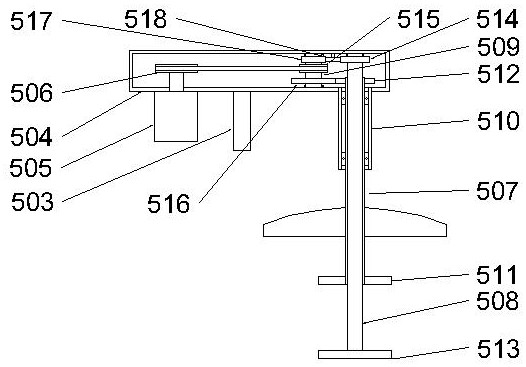

[0015] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 And attached figure 2 , a method for preparing α-cyanoacrylic acid low-whitening glue described in this embodiment, the preparation method includes the following steps:

[0016] 1) Liquefying solid formaldehyde;

[0017] 2) Mix the liquefied solid formaldehyde with the solvent in a reaction vessel to obtain a mixture;

[0018] 3) Add ethyl cyanoacetate and catalyst dropwise to the mixture for polymerization to obtain a reaction system;

[0019] 4) After adding the organic solvent into the reaction system from the bottom of the reaction vessel, condensing and reflux dehydration is carried out to remove the polymer moisture. During the dehydration process, the reaction system begins to appear monomers;

[0020] 5) After the reflux condenser tube and the solvent in the bottle are removed, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com