Size-controllable Ni-NiO heterojunction nanoparticle doped carbon fiber, preparation method and application in lithium-sulfur battery diaphragm

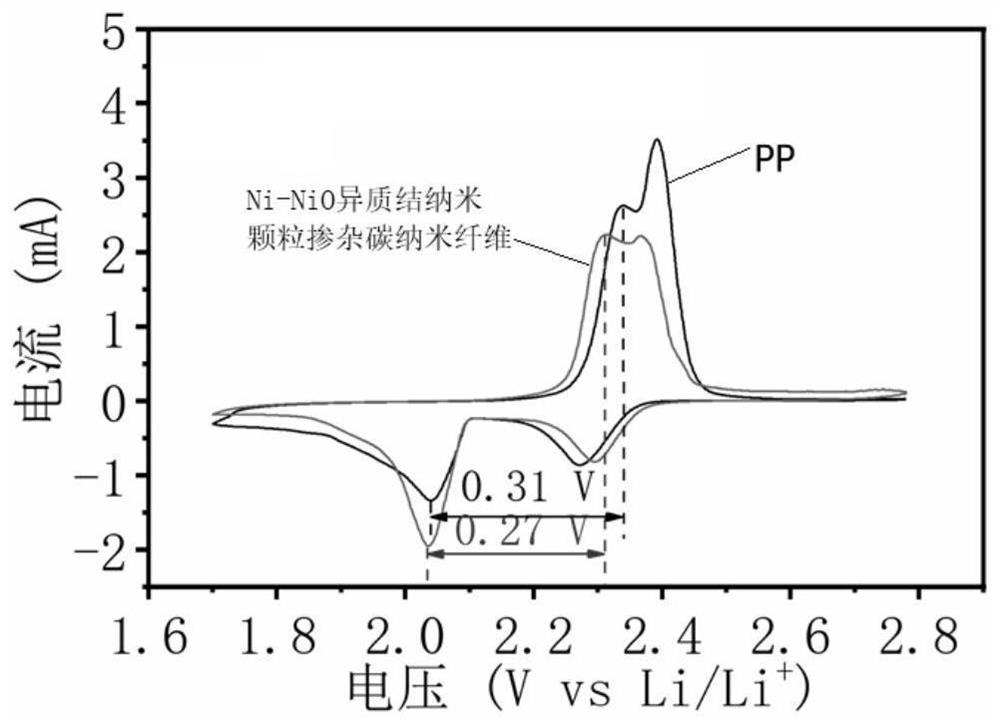

A nanoparticle and carbon nanofiber technology, applied in lithium batteries, non-aqueous electrolyte batteries, nanotechnology, etc., can solve problems such as low rate and capacity reduction, and achieve the effect of increasing initial capacity, improving comprehensive performance, and inhibiting the shuttle effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

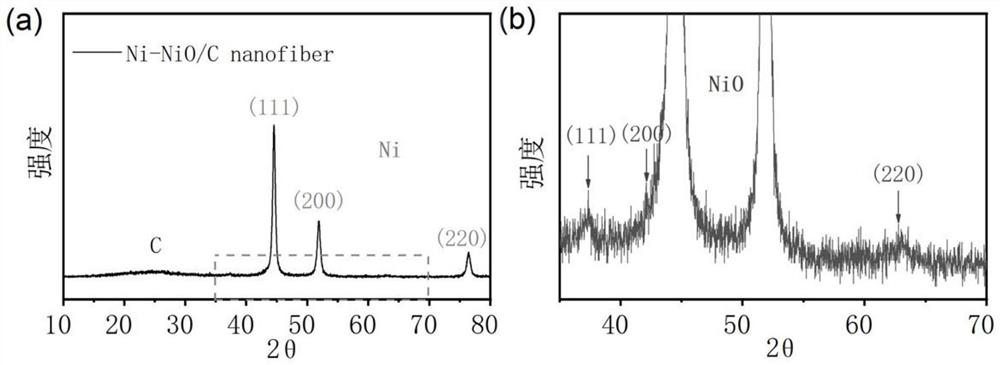

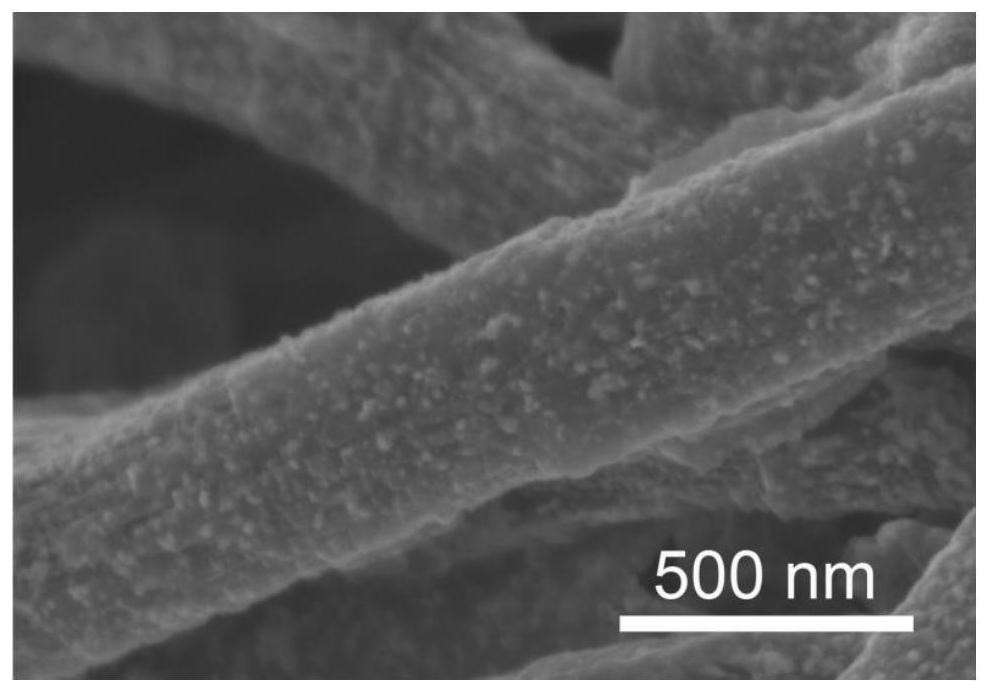

[0055] A method for preparing size-controllable Ni-NiO heterojunction nanoparticles doped carbon nanofibers, comprising the following steps:

[0056] 1) Weigh 0.278g of dimethylglyoxime and dissolve it in 24mL of absolute ethanol, add 40mL of 0.5 mol / L sodium hydroxide solution, adjust the pH of the above solution to 13, and form A solution.

[0057] 2) Weigh 0.521g of nickel chloride hexahydrate and dissolve it in 700mL of deionized water to form B solution.

[0058] 3) Slowly add solution A to solution B, dropwise for 30 minutes, stir at a constant speed of 400 rpm for 30 minutes, let stand for 3 hours, centrifuge, wash with deionized water and absolute ethanol for 5 minutes times, until the pH of the supernatant was neutral, and dried at 60° C. for 10 h to obtain a precursor.

[0059] 4) Put the obtained precursor into a tube furnace and calcinate at 600°C for 1 hour under the protection of argon to obtain ultrafine Ni nanoparticles doped carbon nanofibers.

[0060] 5) Pu...

Embodiment 2

[0075] A method for preparing size-controllable Ni-NiO heterojunction nanoparticles doped carbon nanofibers, comprising the following steps:

[0076] 1) Weigh 0.278g of dimethylglyoxime and dissolve it in 24mL of absolute ethanol, add 40mL of potassium hydroxide solution with a concentration of 0.8 mol / L, adjust the pH of the above solution to 13, and form A solution.

[0077] 2) Weigh 0.521g of nickel chloride hexahydrate and dissolve it in 700mL of deionized water to form B solution.

[0078] 3) Slowly add solution A to solution B, dropwise for 30 minutes, stir at a constant speed for 30 minutes at a stirring speed of 400 rpm, let stand for 3 hours, centrifuge, wash with deionized water and absolute ethanol respectively 5 times, until the pH of the supernatant was neutral, and dried at 60° C. for 10 h to obtain a precursor.

[0079] 4) Put the obtained precursor into a tube furnace, and calcinate at 700° C. for 1 hour under the protection of argon to obtain ultrafine Ni nan...

Embodiment 3

[0089] A method for preparing size-controllable Ni-NiO heterojunction nanoparticles doped carbon nanofibers, comprising the following steps:

[0090] 1) Weigh 0.595g of dimethylglyoxime and dissolve it in 27mL of absolute ethanol, add 45mL of sodium hydroxide solution with a concentration of 0.6 mol / L, adjust the pH of the above solution to 13, and form A solution.

[0091] 2) Weigh 0.318g of nickel chloride hexahydrate and dissolve it in 800mL of deionized water to form B solution.

[0092] 3) Slowly add solution A to solution B dropwise for 30 minutes, stir at a constant speed of 500 rpm for 20 minutes, and let stand for 4 hours to obtain a precursor.

[0093] 4) The obtained precursor is put into a tube furnace, and calcined at 600° C. for 1 hour under the protection of argon to obtain carbon nanofibers doped with ultrafine Ni nanoparticles.

[0094] 5) Place the obtained product in air and calcinate at 300° C. for 2 hours to obtain carbon nanofibers modified with Ni—NiO h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com