Mineral flotation collecting agent, preparation method and application

A technology of mineral flotation and collector, applied in flotation, solid separation and other directions, can solve the problems of restricting the comprehensive utilization level of resources and the need for efficient utilization of difficult mineral resources, achieve excellent collection performance, and be conducive to environmental protection , high-quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

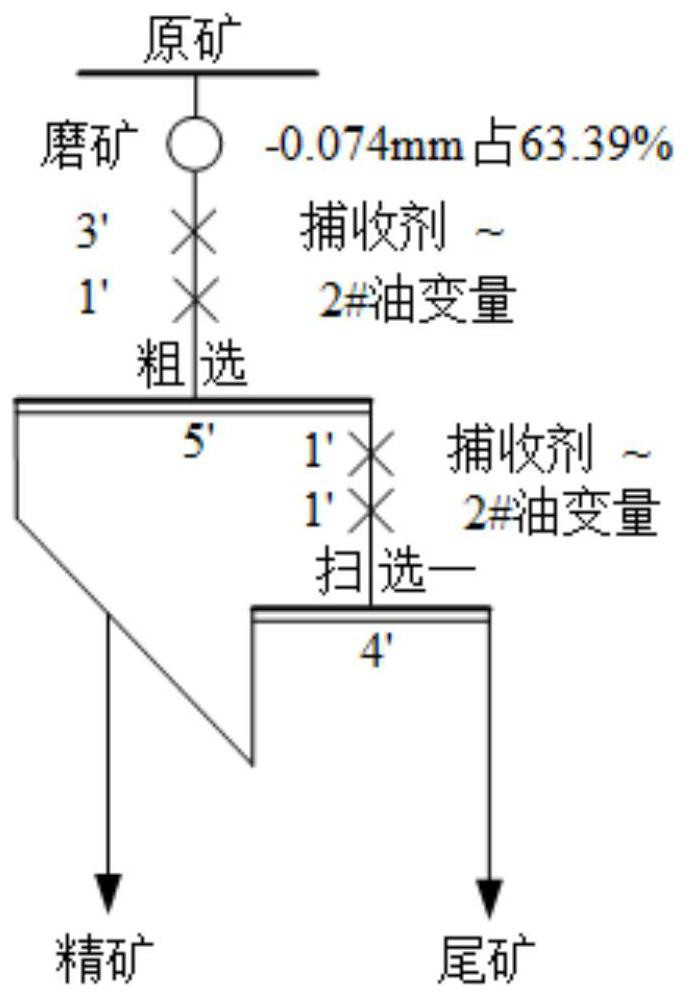

Method used

Image

Examples

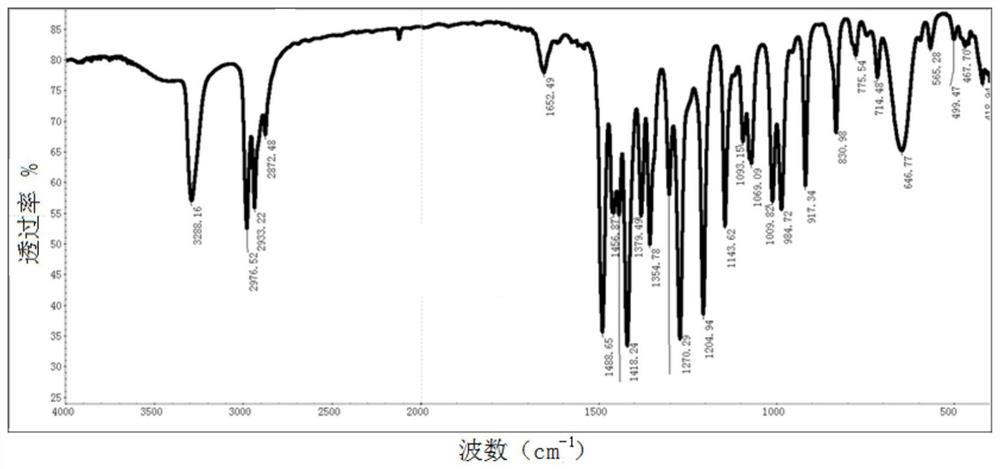

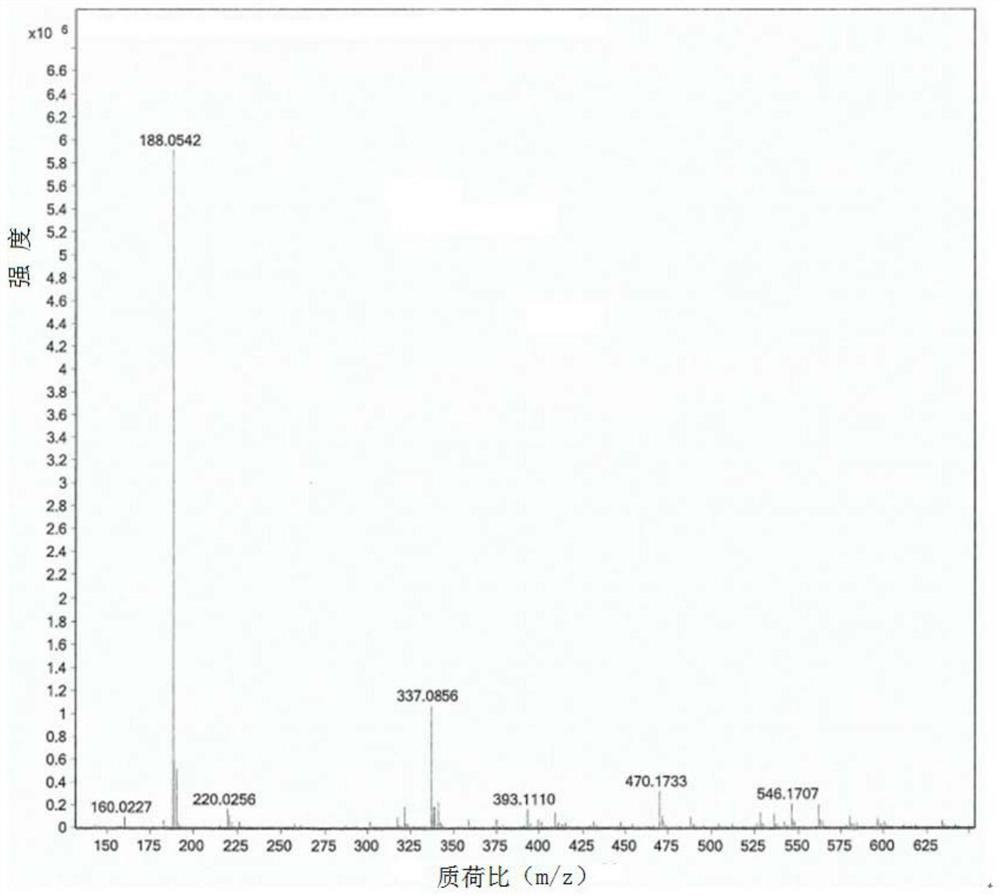

Embodiment 1

[0064] Weigh 0.1 mol of N,N-diethyldithioalkanoate sodium (17.13g) and 45.06g of water, mix and stir for 10min; Slowly add sulfuric acid (30% concentration) dropwise to the mixed solution until the solution pH=6.5, continue to stir for 5 minutes, then add 0.08mol propyne chloride (5.96g) and polybenzyltriphenylphosphorous chloride successively to the mixed solution 0.09g, 0.14g of hydroquinone, then the temperature was raised to 30°C in a water bath, and after stirring for 2 hours, the mixture was naturally cooled to room temperature, left to stand for separation, and the target product N,N-diethyldithioalkyl acid propane The alkynyl ester is separated from the waste liquid, and the product is in the form of black oil. The content of propynyl N,N-diethyldithioalkanoate is detected and calculated to be 86.68%, and the yield is 87.35%.

Embodiment 2

[0066] Weigh 0.1 mol of N,N-diethyldithioalkanoate sodium (17.13g) and 45.06g of water, mix and stir for 10min; Slowly add sulfuric acid (concentration is 30%) to solution pH=7 in the mixed solution, keep stirring for 5 minutes, add 0.09mol chloropropyne (6.71g), tributylamine 0.17g, p-hydroxybenzene successively in mixed solution 0.16g of methyl ether, then heated up to 35°C in a water bath, stirred and reacted for 2 hours, the mixture was naturally cooled to room temperature, left to separate, and the target product N,N-diethyldithioalkyl acid propynyl ester and waste liquid After separation, the product was in the form of black oil. The detected and calculated content of propynyl N,N-diethyldithioalkanoate was 88.41%, and the yield was 90.58%.

Embodiment 3

[0068] Weigh 0.1 mol of N,N-diethyldithioalkanoate sodium (17.13g) and 34.25g of water, mix and stir for 10min; Slowly add sulfuric acid (concentration: 30%) dropwise to the mixed solution until the solution pH=7, continue to stir for 3 minutes, add 0.1mol propyne chloride (7.45g) and 0.13g ethylene glycol dialkyl ether to the mixed solution successively , 0.14g of p-hydroxyanisole, then the temperature was raised to 35°C in a water bath, and after stirring for 4 hours, the mixture was naturally cooled to room temperature, left to stand for separation, and the target product N,N-diethyldithioalkyl acid propyne The ester is separated from the waste liquid, and the product is in the form of black oil. The detected and calculated content of propynyl N,N-diethyldithioalkanoate is 91.37%, and the yield is 93.04%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com