Sodium chloride flotation agent and preparation method thereof

A flotation agent and sodium chloride technology, applied in the field of sodium chloride flotation, can solve the problems of high production cost, high price, large equipment investment, etc., and achieve good flotation effect, short reaction time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

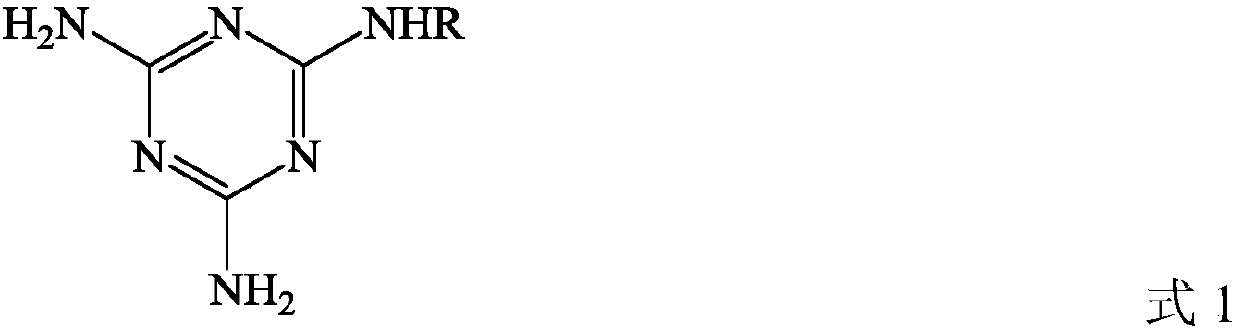

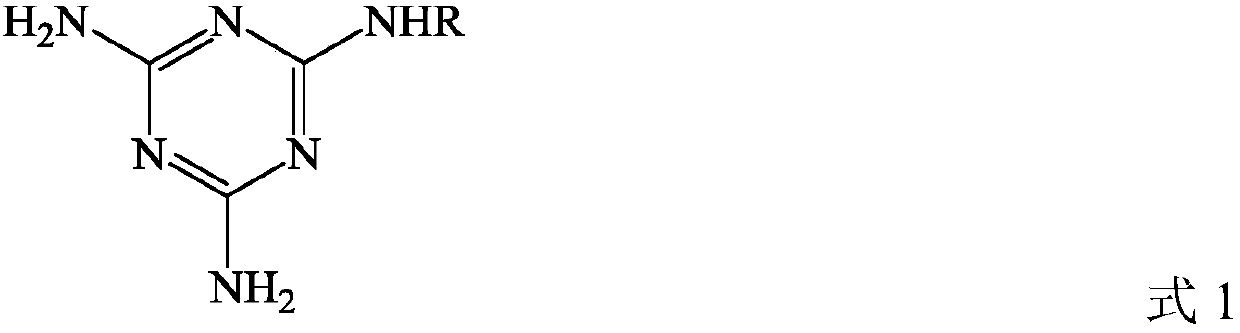

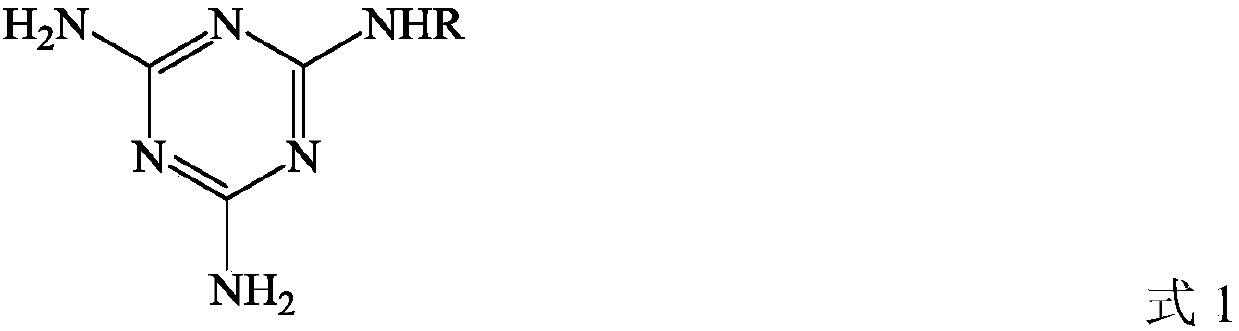

Image

Examples

preparation example Construction

[0025] The present invention also provides the preparation method of above-mentioned sodium chloride flotation agent, it comprises the steps:

[0026] Step S1, heating and dissolving melamine in a dimethyl sulfoxide solution to obtain a first reaction system.

[0027] Generally, it is sufficient to heat the melamine to about 80°C.

[0028] Step S2, adding halogenated linear alkanes to the first reaction system to obtain a second reaction system.

[0029] Specifically, the ratio of the amount of melamine to the halogenated straight-chain alkane is controlled to be 0.5:1 to 5:1, and the number of carbon atoms in the halogenated straight-chain alkane is not less than 6, preferably 9 to 12, Twelve are more preferable.

[0030] Preferably, the halogenated linear alkanes are in particular 1-halogenated linear alkanes, and preferably 1-bromododecane.

[0031] Step S3, adding sodium bicarbonate or sodium hydroxide to the second reaction system, and reacting at 80° C. to 200° C. for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com